what is yarn-dyed?

Yarn-dyed weaving refers to the process of dyeing yarn or filament and then weaving with colored yarn. Different from the printing and dyeing method of printing and dyeing the woven fabric, the dyed fabric first dye the yarn and then uses colored yarn for weaving, which has a unique style.

The color of dyed fabrics is mainly bright and bright, and the pattern is also distinguished by color contrast. Generally speaking, yarn-dyed fabric refers to the fabric woven by shuttle loom, but the knitting machine can also make yarn-dyed knitted fabric.

Yarn-dyed fabrics can be divided into full-color fabrics and half color fabrics

Full-color weaving: dyed or partially dyed yarn in both warp and weft (or several colored yarns in the fabric are interwoven with white yarn).

Semi dyed: warp or weft yarns are dyed or partially dyed.

Reasons for adopting full-color weaving:

❶ in order to achieve the effect of different colors – the post-treatment of dyeing and printing of the same raw material with different colors cannot be done, but yarn-dyed weaving can be used.

❷ requirements for colorfastness and color light – yarn-dyed products have good colorfastness and color light feeling. C. requirements for a sense of hierarchy – a good sense of hierarchy is required.

Reasons why the fabric is semi colored:

① Different warp and weft raw materials – different warp and weft yarn raw materials have different requirements for dyeing performance, so semi-colored weaving can be used.

② Reduce costs and increase fancy.

Difference between yarn-dyed fabric and printing dyeing

Yarn-dyed weaving – dyeing the yarn and then weaving with colored yarn, such as many shirt fabrics, denim, etc.

Printing and dyeing – printing and dyeing of woven fabrics, such as many, many printed fabrics, with rich and colorful patterns.

Characteristics of dyed fabrics

Advantage

Strong three-dimensional sense: dyed fabrics use different colored yarns to cooperate with the fabric structure to form various beautiful patterns, which have a three-dimensional sense than ordinary printed fabrics.

Good color fastness: because the dyed fabric is dyed with the original yarn, the dye permeability is strong, so the color fastness is good.

Rich colors: yarn-dyed fabrics are woven by multi shuttle and multi arm weaving, which can interweave different fibers or different yarn counts into varieties with rich colors and smart patterns.

Unique style: due to the use of colored yarn or fancy yarn and various organizational changes, dyed fabrics can be woven into beautiful and unique varieties.

Shortcomings

Due to the large loss of processes such as yarn dyeing, weaving, and finishing, the output of Taiwan production is not as high as that of white cloth, so the input cost is high and the technical requirements are high.

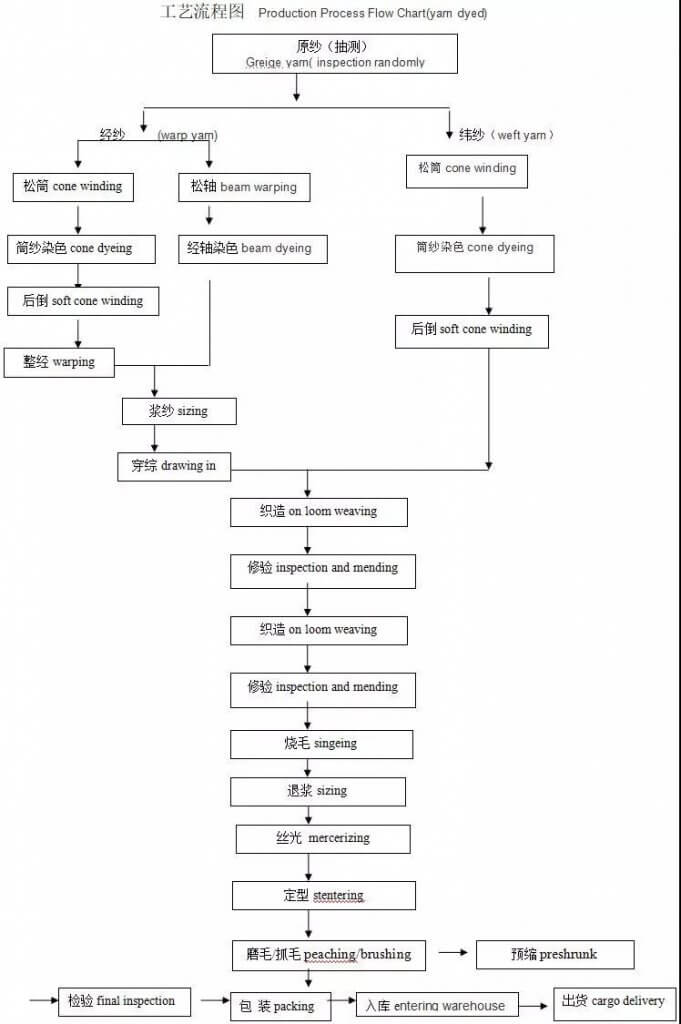

The production process of yarn-dyed fabric factory

The production process of dyed fabrics can be divided into cylinder dyeing and shaft dyeing according to warp dyeing. Barrel dyeing can be used regardless of the single quantity, but its process is long and brings some inconvenience to the cost control. The process of shaft dyeing is short, the loss of warp yarn is small, and the cloth color is well controlled. According to the current equipment configuration of our company, it is suitable for single quantity dyeing above 2000 meters.

According to different processes, the yarn-dyed fabric factory is divided into three main workshops: dyeing workshop, weaving workshop, and finishing workshop. In addition, production planning, equipment dynamic} force, process technology, and other departments are set up. The following mainly introduces three processes: dyeing, weaving, and finishing.

Circular knitting machine

Large circular knitting machine, scientific name: circular knitting weft knitting machine (or circular knitting weft knitting machine). The large circular knitting machine has developed rapidly due to its many loop forming systems (called the number of yarn feeding routes or loop forming routes in enterprises, referred to as the number of routes), high speed, high output, rapid pattern change, good fabric quality, few processes, and strong product adaptability

Related article

Rare earth heating fibers

Textile fabric width control

Several types of regenerated fibers that are easily confused.

Read moreSeveral types of regenerated fibers that are easily confused.

Key technologies for double-sided circular knitting machine needle plate calibration

Read moreKey technologies for double-sided circular knitting machine needle plate calibration

How a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)

Read moreHow a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)