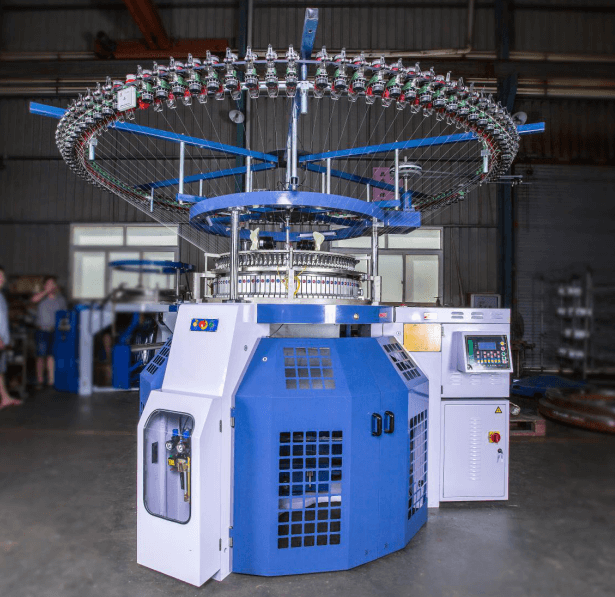

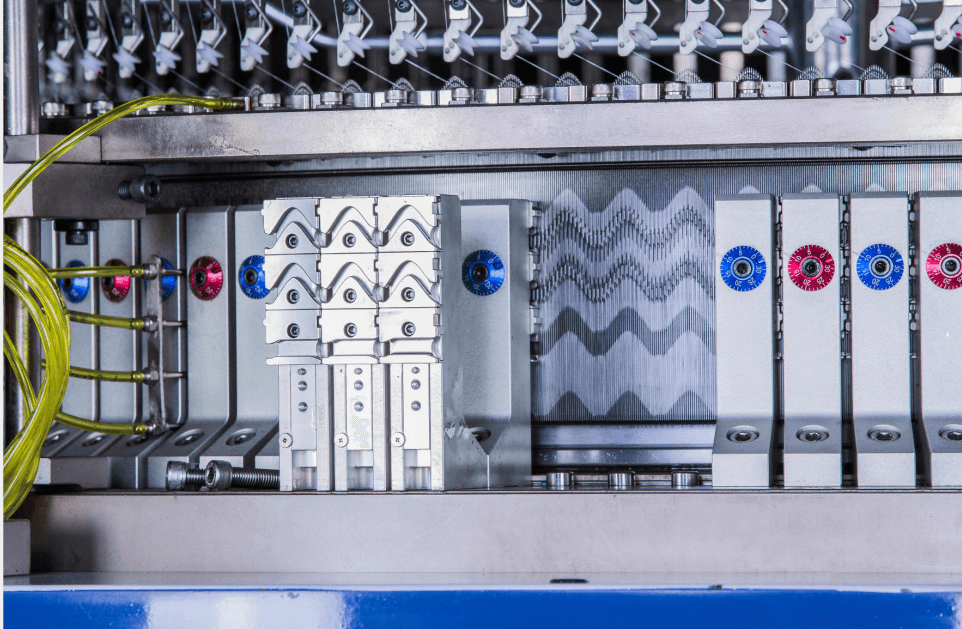

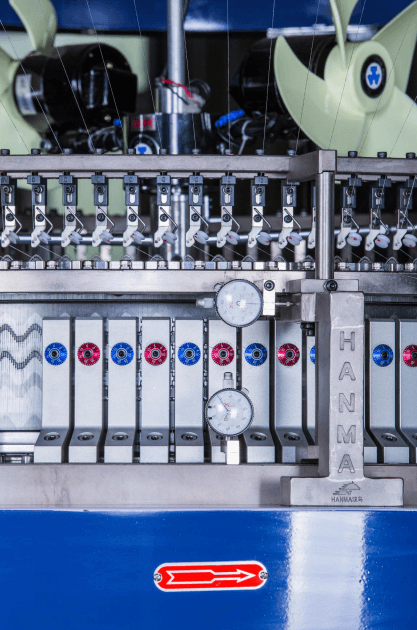

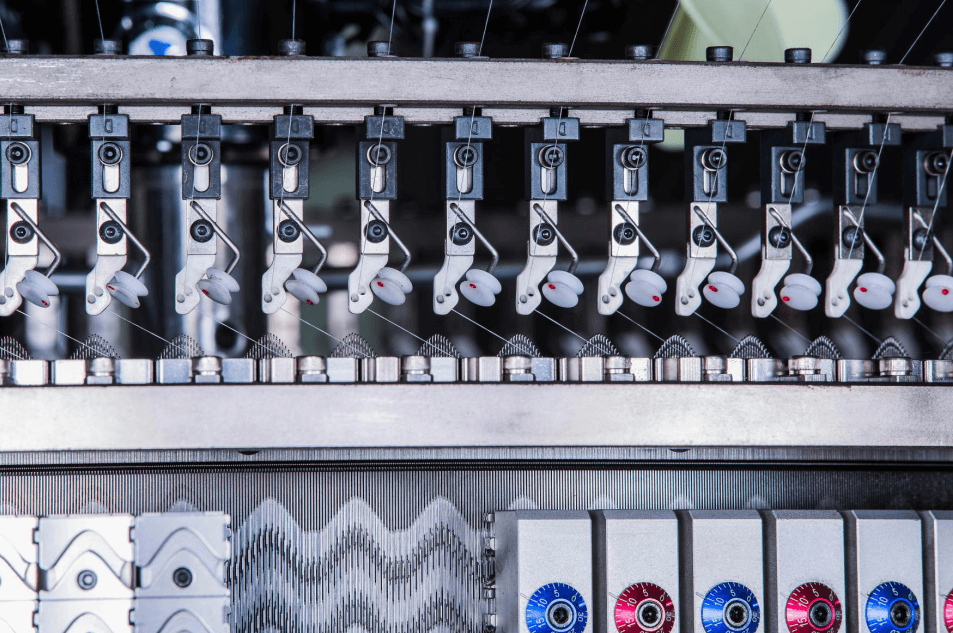

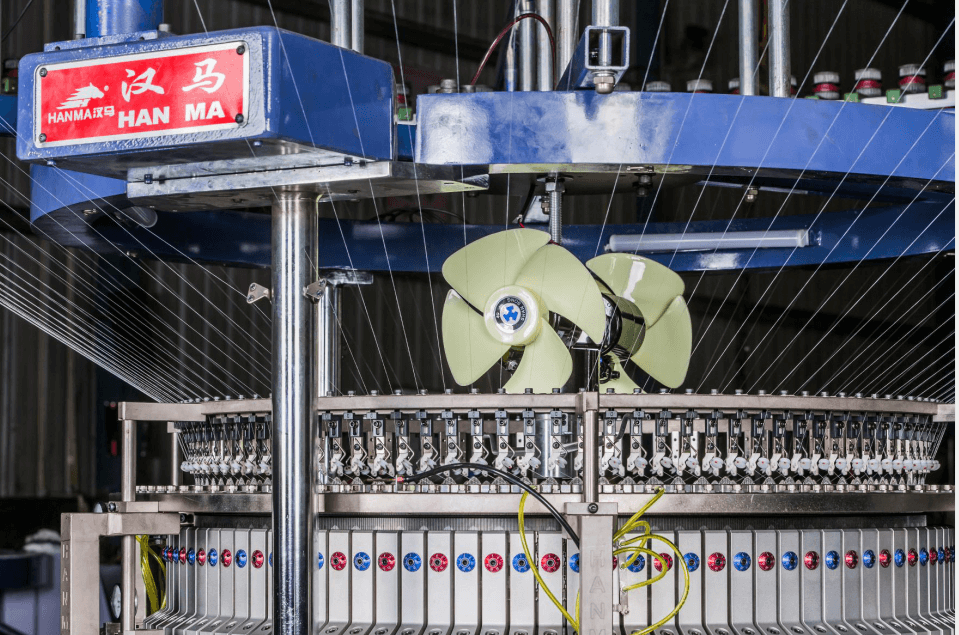

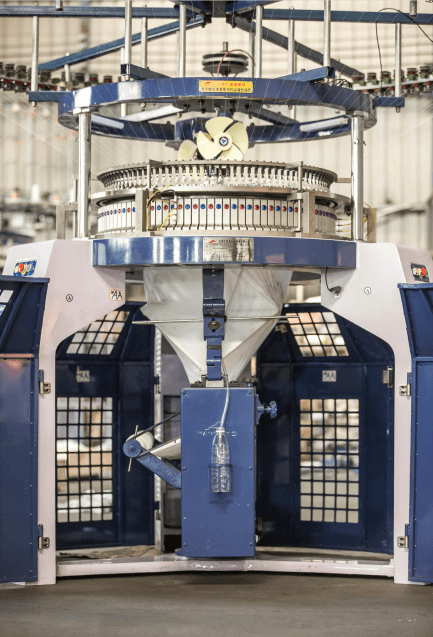

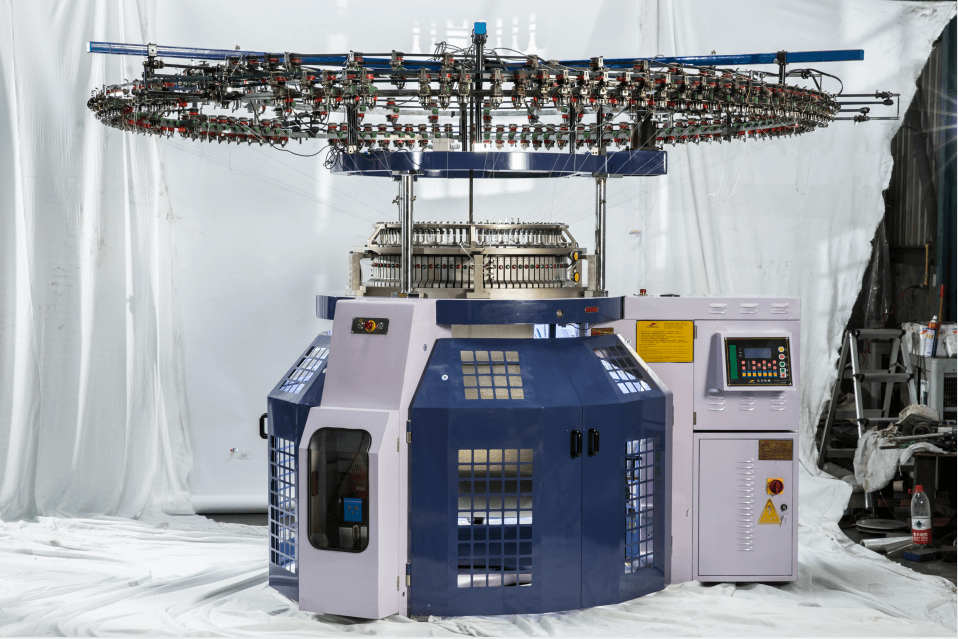

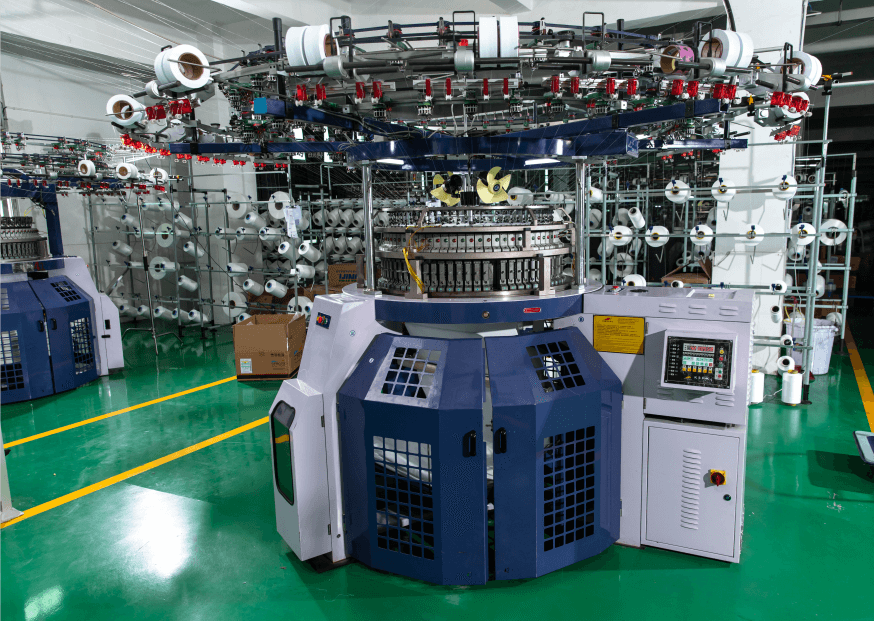

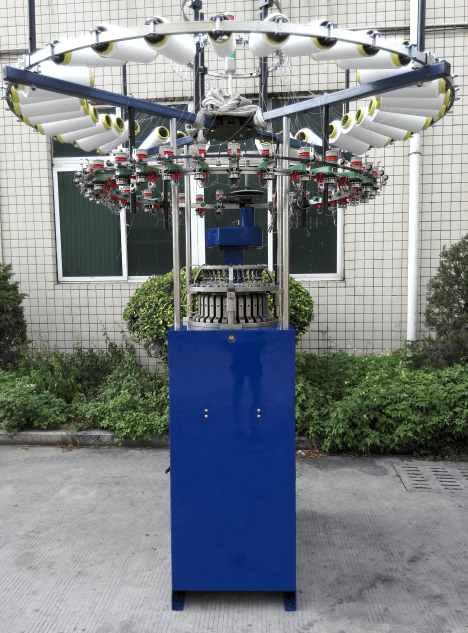

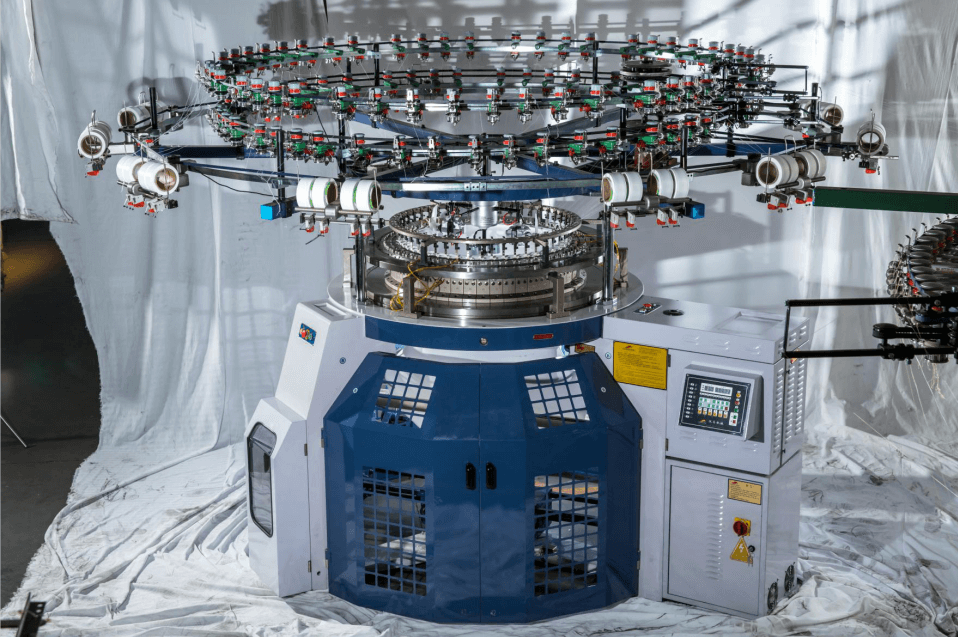

It adopts four-track cam design of closed type with Draw-down cam, Tuck cam, Floating threads cam. Central total lift can easily and quickly adjust the weight of fabric; mouth feeding yarn with specially design makes the increase of spandex with facility. Use humanization design, additional feed yarn intermediate ring is easy observation and wearing yarn of operator, instead of touching the operator’s head of yarn; at the same time, making yarn delivery more fluid and smooth, to meet the requirements for high-speed weaving of machine. Sophisticate structural design makes needle cylinder more convenient to replace, through different triangular arrangements, a variety of tissue fabrics can be produced, such as: mercerized cotton, polyester cover cotton, striped fabric, scouring pads, single and double lacoste mesh fabric, elastic couth, scale loop +spandex, cotton spandex single jersey, etc. Products are used to vest, T-shirt, sportswear, aerobic suit, and swimming suit.

One machine has lots of functions, and single-surface machine can be converted into sweater machine or towel machine just by changing key parts;

Single jersey horizontal knitting frame was first made in 1589 by William Lee. Single jersey machine can only produce plain. Plain is the simplest type of structure practiced since the inception of knitting technology. It can be done in hand knitting as well as machine knitting (flat and circular). Although stockings, gloves and caps were the main uses of plain hand-knitted structures in the past, now it has wide application in the manufacture of inner and outer garments.

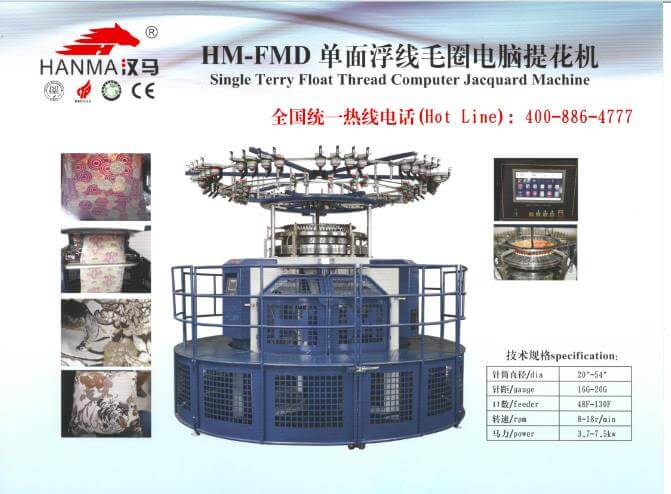

Diameter:8″-68″

Gauge:15G -44G

Feeder:24F -408F

Speed:16-30r/min

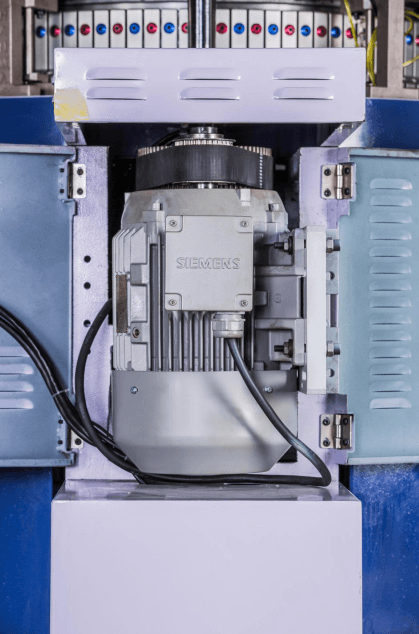

Power:2HP -11.5HP

Premium Quality Lycra can be made (For Spandex Manufacturing)

With our special design of the feeding yarn carrier, Lycra can be made as soft, elastic, flexible and more proficient than ever.

Featuring an ergonomic design, the additional middle feeding yarn transfer ring makes it easy for personnel to monitor and carry yarn, without the machine touching the operator’s body; at the same time, the yarn carrying system is freer and steadier, satisfying the demand of machine operating and knitting at high speeds.

Flexible for Knitting Varying Fabrics and Multi-functional Models

This conventional single jersey circular knitting machine can perform multi-purpose functions by just replacing the heart parts. Easy conversion into 3-thread-fleece and terry machine and other machines can be performed.

| Condition: New | Product Type:fabric | Type:Circular | Production Capacity:250-750kg |

| Place of Origin: Fujian China (Mainland) | Brand Name:HANMA (circular knitting machine) | Model Number:HM-DF4 (circular knitting machine) | Power(W):5.5kw (circular knitting machine) |

| Knitting Style: knitted | Knitting Method: Single | Computerized: No | Weight:2.5TON |

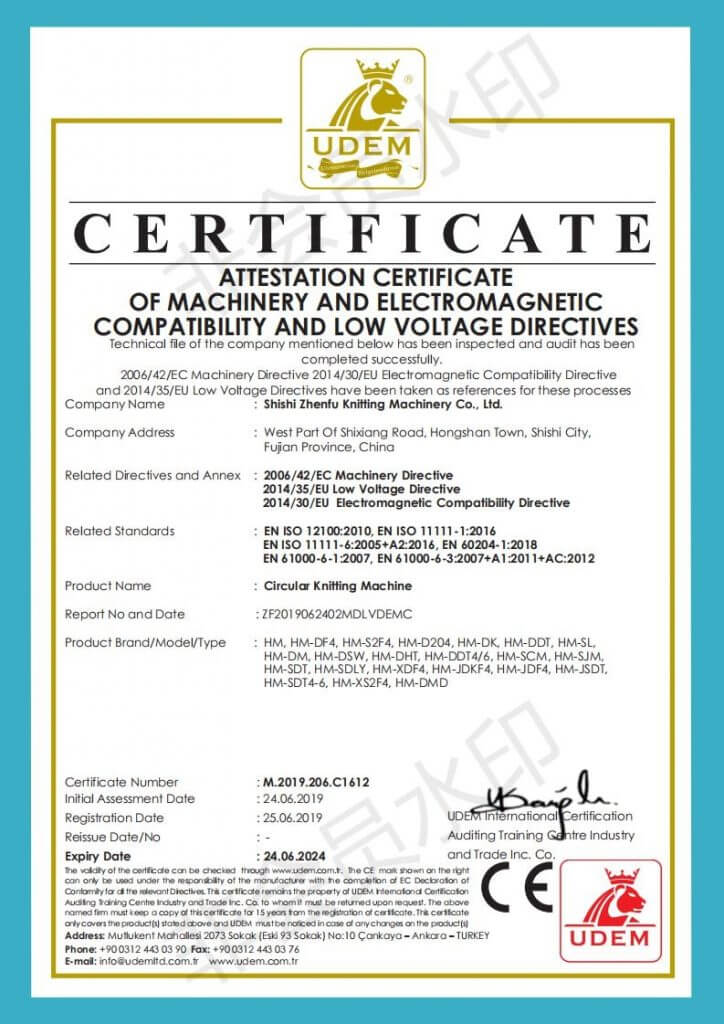

| Dimension(L*W*H):2.35*2.28*2.28M | After-sales Service Provided:Engineers available to service machinery overseas | speed:0-30RPM | Certificate: CE |

| machine type: single jersey | turn way: anticlockwise | fabric function:sports garment |

There are many types of circular knitting machine that produce long lengths of tubular fabric manufactured for specific end uses. Single jersey machines are equipped with a single ‘cylinder’ of needles that produces plain fabrics, about 30 inches in diameter. Wool production on single jersey machines tends to be limited to 20 gauge or coarser, as these gauges can use two-fold wool yarns. The cylinder system of single jersey machines is demonstrated in Fig. 7.1. Another inherent feature of woollen single jersey fabrics is that the fabric edges tend to curl inwards. This is not a problem whilst the fabric is in tubular form but once cut open can create difficulties if the fabric is not finished correctly. Terry loop machines are the basis for fleece fabrics that are produced by knitting two yarns into the same stitch, one ground yarn and one loop yarn. These protruding loops are then brushed or raised during finishing, creating a fleece fabric. Sliver knitting machines are single jersey machines that have been adapted to trap a sliver of staple fibre into the knit structure.

| No | Description | Supplier | Brand | Quantity |

| 1 | Insert flake type cylinder &dial(Germany metal) | Hanma | China | 1 unit |

| 2 | Needles | Groz-beckert | Germany | 1 set |

| 3 | Sinkers | Kern liebers | Germany | 1 set |

| 4 | Positive storage yarn feeders | Hanma | China | 1 unit |

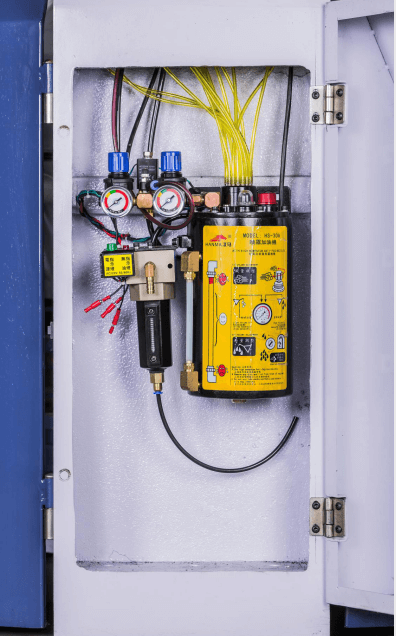

| 5 | Oiling lubricator | Hanma | China | 1 unit |

| 6 | Yarn creel | Hanma | China | 1 set |

| 7 | One ways Take-down device | Yong tai | Taiwan | 1 set |

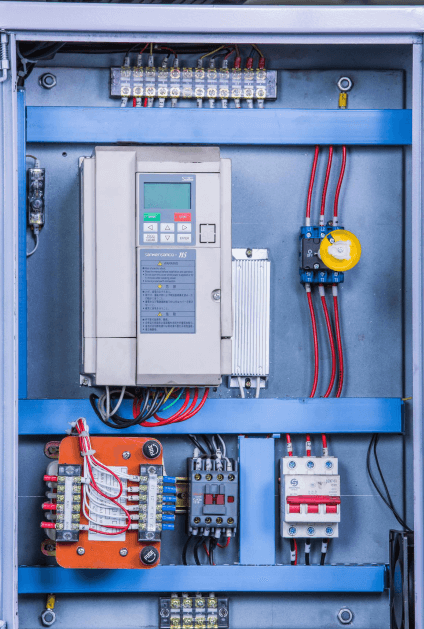

| 8 | Invertors for motor controller | Sunyue | Taiwan | 1 set |

| 9 | fabric Spreader equipment | Hanma | China | 1 set |

| 10 | cam | Hanma | China | 1 set |

| 11 | Control panel | Hanma | China | 1 set |

| 12 | Automatic dust fans with blower equipment. | San song | China | 1 set |

| 13 | Radar type round 360”Clear dust equipment | San song | China | 1 set |

| 14 | Motor | Hanma | Taiwan | 1 set |

| 15 | Spare tools | 1 set | ||

| 16 | Operation manual for invertors & controller panel | 1 set | ||

| 17 | Extra Spare parts : (a) 100pcs needles (b)100pcs sinkers (c)Feeders 1pcs (d)Air blower gun 1 set (e)Fuse 4pcs (f) Yarn carrier 1pcs (g)Needle oil 1 liter |

| Product Name | Organic 100% Cotton Combed Single Jersey Knit Fabric |

| Composition | 100% cotton |

| Weight | 190GSM |

| Width | 58/60″ |

| Product Number | FM-2676 |

| Usage | usually for t shirt, other garments according to your requirements |

| MOQ | 400KGS |

Related Product

Related Article

Related RFQ

Company Profile

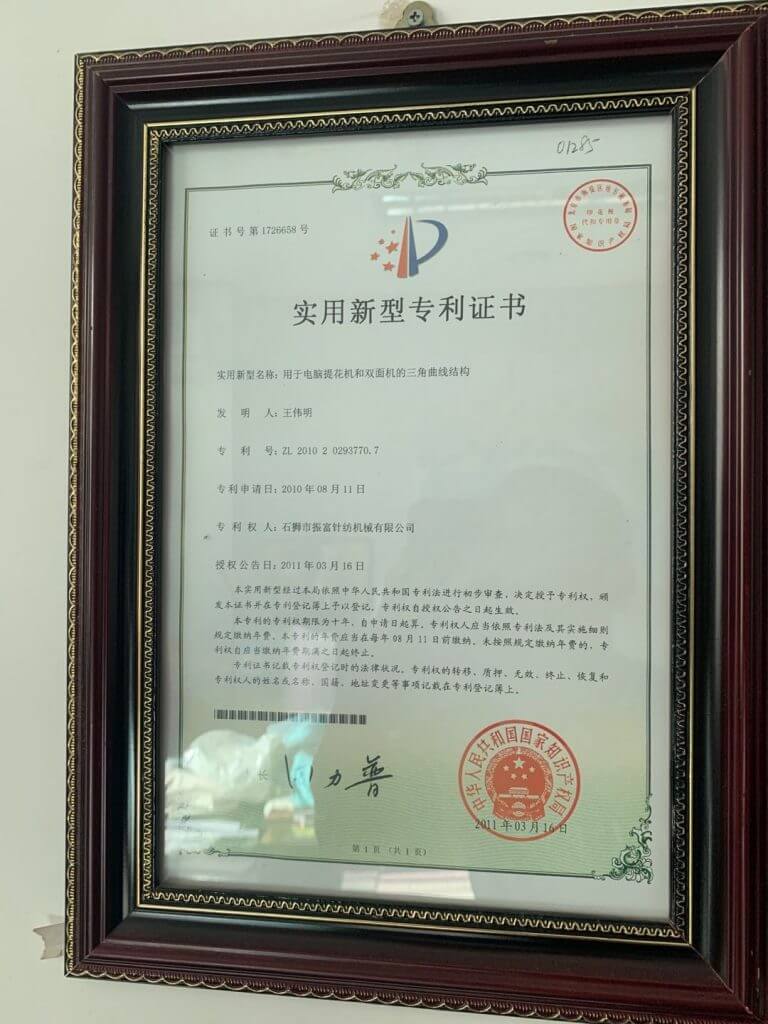

Zhenfu Knitting Machinery Co., Ltd. is a professional enterprise specializing in manufacturing machines, woven products, and apparel. We are also engaged in the production and design of fabrics and large diameter circular knitting machines for woof weaving and knitting. We have three trademarks — “HANMA”, “LUHU”, “ZHENFU”.We introduced foreign advanced computer process equipment and test and measurement instruments. We also research information reflection from consumers for stratifying customers’ different demands. We have a group of engineer technicians with rich experience. They can develop new products according to customers’ specifications. We are based on the enterprise tenet of “Credit, Factualism, and Innovation” and persist in the management concept of “Quality is the Base and Credit is the First”. We can supply top-ranking products and perfect after-sales services to our customers. We have taken root in a vehemently competing market of diameter circular knitting machines. Our company was awarded ISO9001 certificate in 2003. We have developed into a production factory with a certain scale. We offer large diameter circular knitting machines, including rib universal machines, large high-speed and single-sided jacquard cylinders, high-speed and single-sided large diameter circular knitting machines, back-to-face packed pole loop machines, and single-sided sanitary clothes. We welcome all clients to contact us.

In 2015 Hanma circular knitting machine show in Italy exhibition. Hanma company is a professional circular knitting machine factory. We are manufacturing circular knitting machines for 17 years, our products have high stability, high speed, and easy operation. We have to sell all over the world.