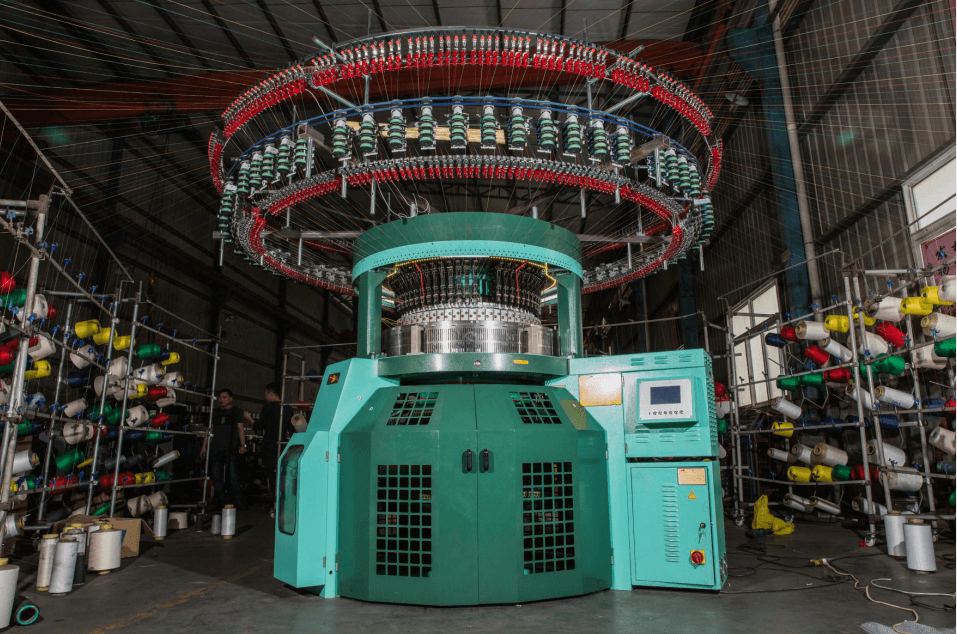

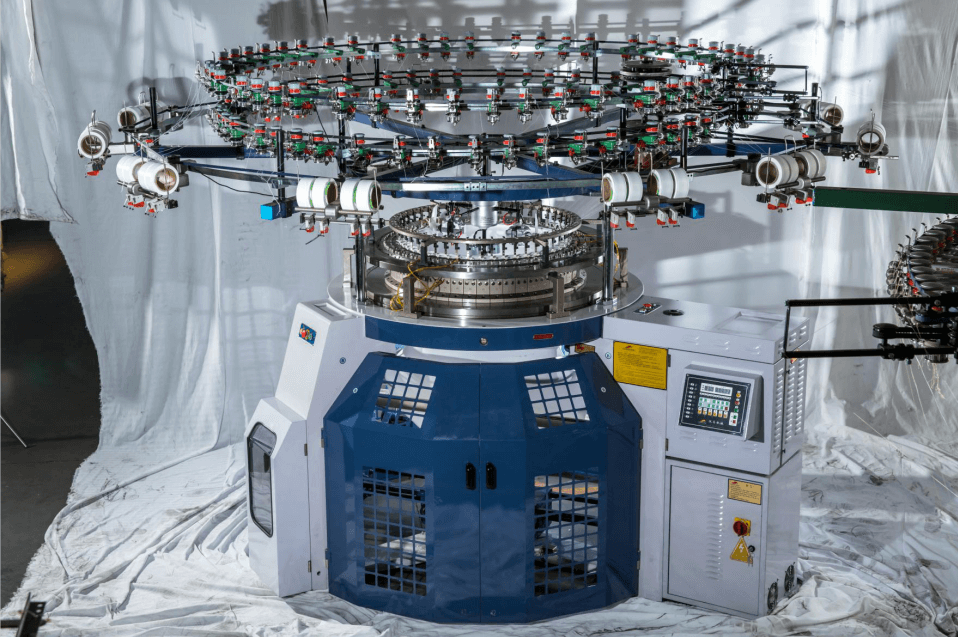

Circular knitting machines are generally divided into two categories: single-sided series and double-sided series. But according to the types of fabrics processed and produced (academically called fabrics. Commonly called grey fabrics in factories), there are the following types:

Single side series

The single jersey circular knitting machine is a machine with a needle cylinder. Specifically divided into the following categories.

Ordinary single jersey circular knitting machine

Ordinary single jersey knitting machines have many loops (usually 3~4 times the diameter of the needle cylinder, that is, 3 routes∕25.4mm~4 routes∕25.4mm). For example, a 30″ single jersey machine has 90F~120F, The 34″ single-sided machine has 102~126F circuits, etc., with high speed and high output. In our country, some knitting enterprises are called multi-triangular knitting machines (mainly arising from the Z241 type).

Ordinary single jersey circular knitting machines have single needle tracks (one track), two-needle tracks (two tracks), three needle tracks (three tracks), four needle tracks, and six needle tracks. Most of them are currently used in knitting enterprises. The four-needle single-sided circular knitting machine is used. It uses the organic arrangement and combination of knitting needles and triangles to weave various new fabrics.

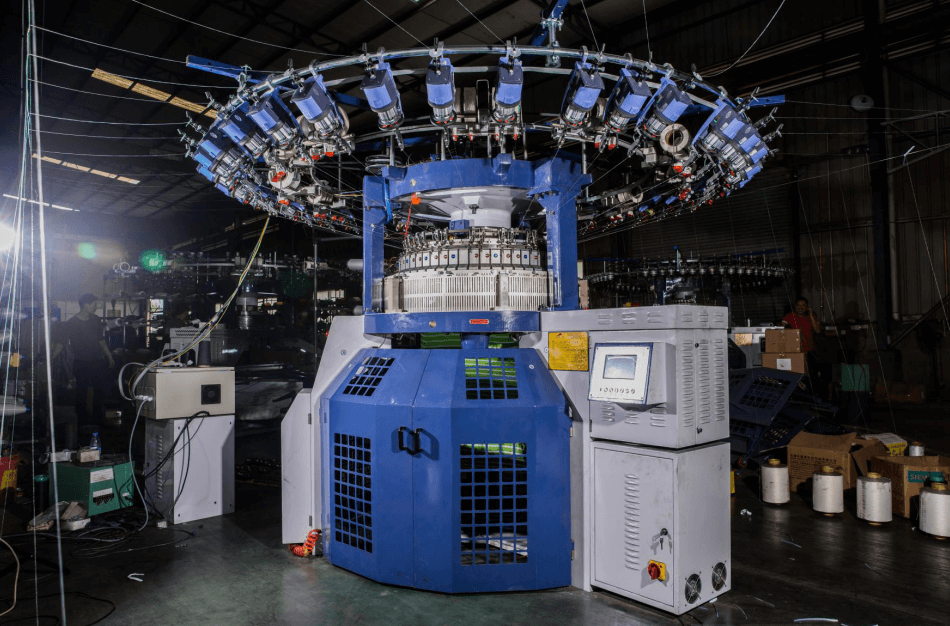

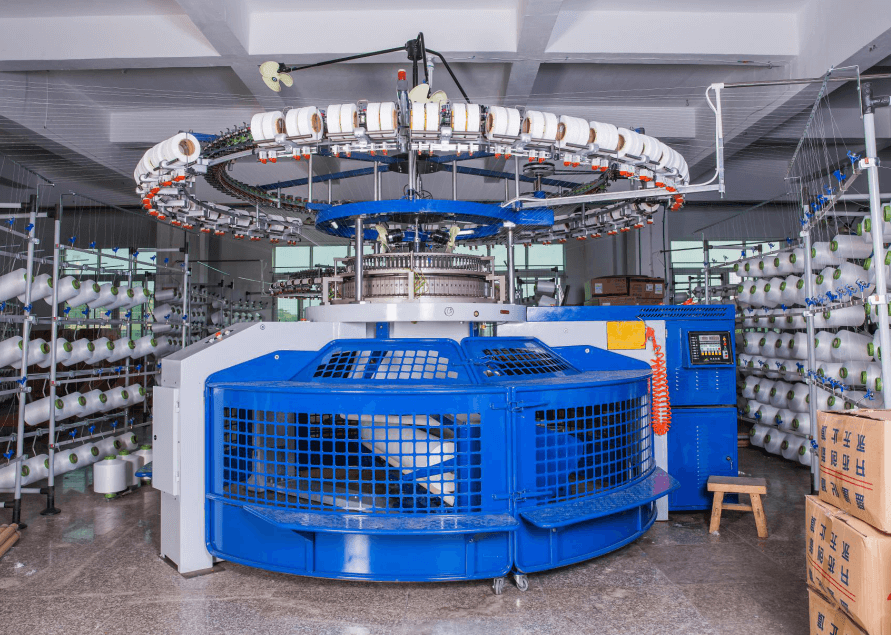

Single terry machine

Single terry machine is also called a single towel machine. It has a single needle track, double-needle track, and four needle track models, and has a positive wrapping terry machine (the terry yarn wraps the ground weave yarn inside, that is, the terry yarn is displayed on the front of the fabric. The yarn of the organization is covered in it) and the turn-up terry machine (that is, the terry fabric we usually see, the yarn of the ground weave is on the opposite side of the fabric), which uses the arrangement and combination of sinkers and yarns. To weave and produce new fabrics.

Three-thread circular knitting machine

The three-thread circular knitting machine is called a sweater or flannel machine in knitting enterprises. It has single-needle, double-needle and four-needle models, which are used to produce all kinds of fleece and non-pull fleece products. He uses knitting needles and arranging yarns to produce new fabrics.

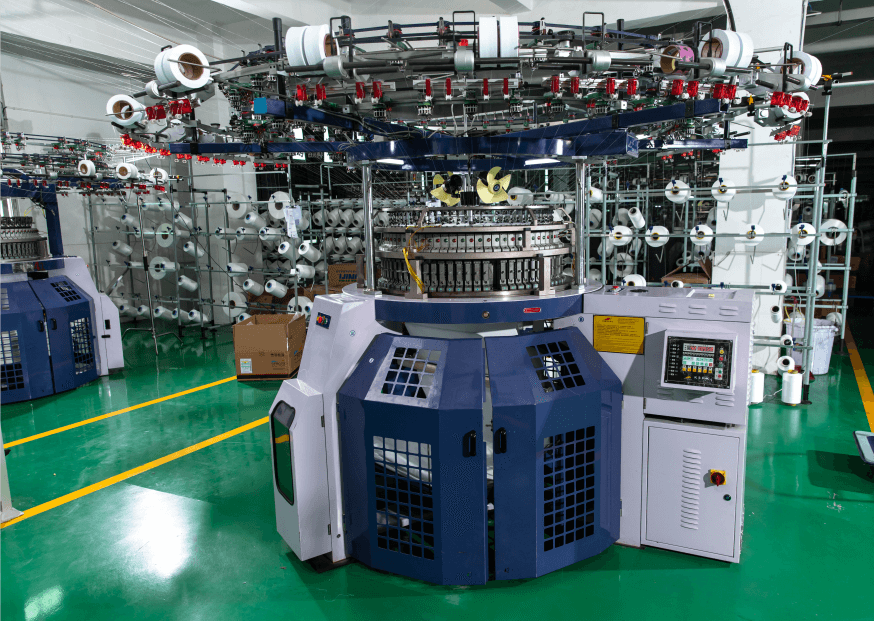

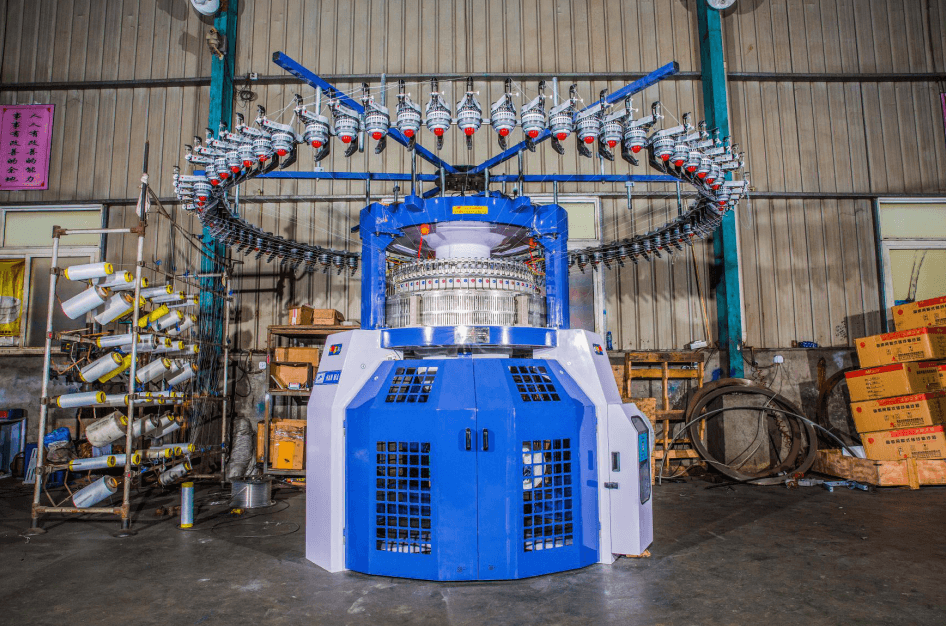

Single jersey Jacquard circular knitting machine

Single jersey Jacquard circular knitting machine has two types: small jacquard machine and large jacquard machine.

1) Small single jacquard circular knitting machine

Small jacquard circular knitting machines are called mechanical jacquard knitting machines in knitting enterprises. It is simple, convenient, and quick to change varieties, but it has low speed and low output. It has several types of jacquard wheel type (commonly known as flower plate type), pick type (swing type), drum type, and insert type. It is used to weave and produce various single-sided small jacquard fabrics, with ordinary single-sided and ordinary loops. , Sweaters, transfer loops, and other small jacquard machines.

2) Large single jacquard circular knitting machine

Large single jacquard circular knitting machine is commonly known as a computer jacquard circular knitting machine because it inserts the designed floppy disk into the computer, and then enters the program to perform knitting production, so it is also called the fool circular knitting machine. The machine adopts a computer program to select knitting needles for knitting, non-knitting, and tucking. There are two power positions (loop formation and floating yarn, loop formation, and tuck) and three power positions (one way can simultaneously knit, tuck and float ) It is used to knit and produce knitted fabrics with large patterns, and can change the color of the yarn. There are four colors, five colors, six colors, and eight colors that can be changed mutually, with large jacquard single-sided, jacquard wool Jacquard machines for loops, jacquard sweaters, transfer loops, etc.

The computer jacquard knitting circular knitting machine greatly shortens the product design cycle, reduces the cost of the circular knitting machine, and greatly improves the product quality, which improves the economic and social benefits of the enterprise, and at the same time improves the competitiveness and resilience of the enterprise.

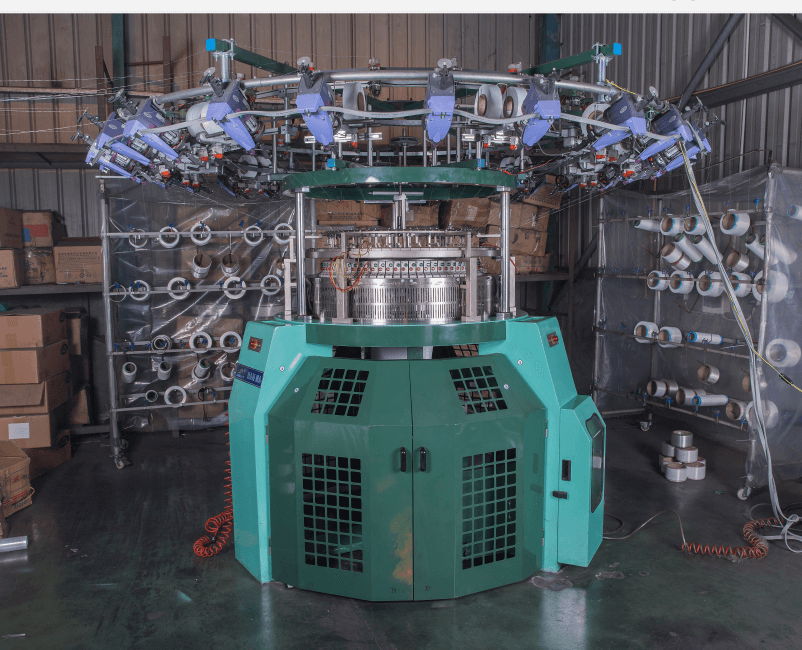

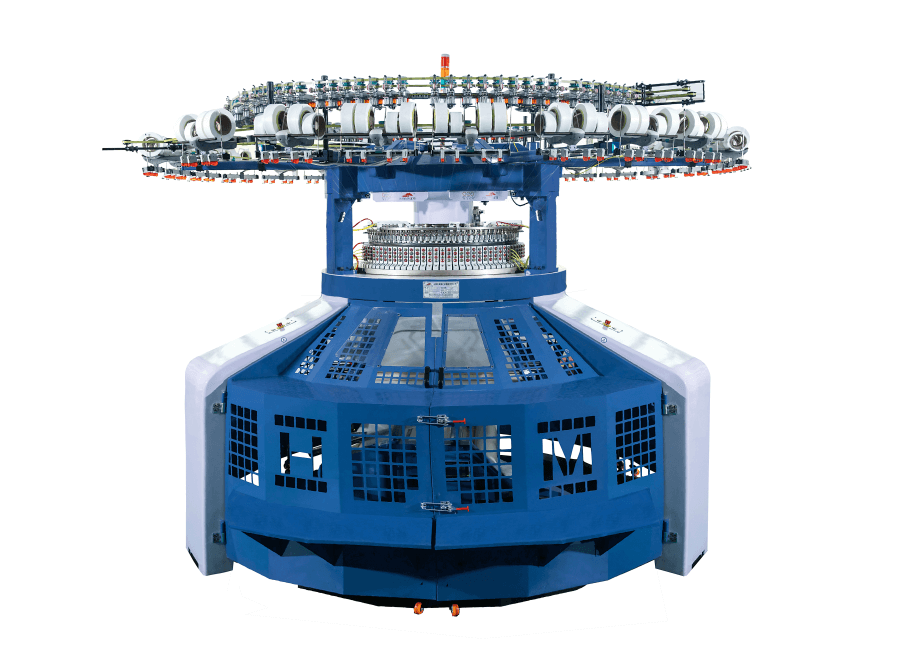

Double jacquard circular knitting machine

The double jacquard circular knitting machine is a circular knitting machine with two-needle cylinders, namely an upper needle cylinder (commonly known as a needle plate) and a lower needle cylinder, and are arranged perpendicular to each other, that is, the needle plate and the needle cylinder are arranged vertically at 90 degrees. It mainly has the following types.

Rib knitting machine

The rib knitting machine is a special model of a double-sided circular knitting machine. It has (1+1) needle track (one needle track on the dial, one needle track on the needle cylinder), (2+2) needle track, (2+4) needle track, and (4+4) needle track. Use the mutual arrangement and combination of triangles and knitting needles and yarn arrangement to weave and produce new knitted fabrics.

Ordinary double jersey circular knitting machine

An ordinary double jersey circular knitting machine is also called a cotton wool machine, multi-function machine, universal knitting machine, etc. It also has a (1+1) needle path, (2+2) needle path, (2+4) needle path, and rib knitting machine. (4+4) Needle path. The newly introduced knitting circular knitting machine companies, in order to produce more varieties of patterns, mostly use (2+4) needle circular knitting machines, which use the mutual arrangement and combination of triangles and knitting needles and yarn arrangements to knit Production of new knitted fabrics

Double Jacquard circular knitting machine

The double jacquard circular knitting machine has two types: small jacquard machine and large jacquard machine.

1) Small double jacquard circular knitting machine

Same as the small single jacquard knitting circular knitting machine, with small double-sided jacquard knitting machines such as an ordinary rib, double-sided, and transfer loops.

Large double jacquard circular knitting machine

- Same as a large-scale single jacquard knitting circular knitting machine, with large-scale jacquard double-sided jacquard and transfer jacquard machines.

In addition, there are some special large circle machines, namely transfer large circle machine (including transfer rib machine, single-sided transfer large circle machine, double-sided transfer large circle machine, etc.), double-sided terry machine (that is, the fabric has a loop effect on both sides of the fabric ), single-sided machine on the tube (ie double-reverse round machine)

Related product

Computerized Single Jersey Auto-Striper circular Knitting Machine

Computerized Single Jacquard Circular Knitting Machine

Computer Jacquard circular knitting machine

DOUBLE JERSEY JACQUARD CIRCULAR KNITTING MACHINE

DOUBLE JERSEY AUTO-STRIPER CIRCULAR KNITTING MACHINE (FOUR/SIX COLORS)

DOUBLE RIB JACQUARD CIRCULAR KNITTING MACHINE

Related Article

What is heat-setting knowledge?

circular knitting machine guide

what is Basic knowledge of circular knitting

What is the Knowledge of knitted fabrics

what is the kind of circular knitting machine

Circular knitting machine basic operation knowledge

Read moreCircular knitting machine basic operation knowledge