- Classification of knitted fabrics

knitted fabric is made of continuous loops. According to the continuous loop formation method, it can be divided into two types, namely warp knitting and weft knitting

Circular knitting

Weft Knitting

Knitting Flat knitting

Warp knitting - Weft-knitted yarns are bent into loops in the transverse direction and stringed together to form a fabric.

- Warp-knitted yarns are bent into loops in the longitudinal direction and stringed together to form a fabric.

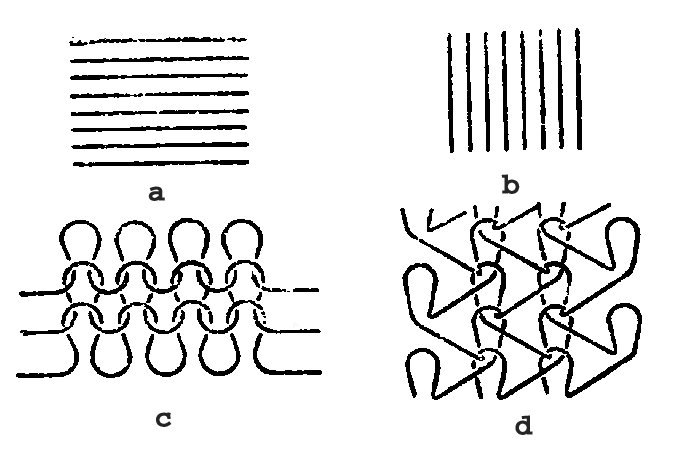

Figure 1-1

The yarn is bent to form a knitted fabric

a-Horizontal yarn knitting system

b-Longitudinal yarn knitting system

c-Bending of transverse yarns

d-Bending of longitudinal yarns

- Single jersey and double jersey

knitted fabrics can be divided into single jersey knitted fabrics and double-sided knitted fabrics.

Single jersey: fabric knitted with a single needle bed.

Double jersey knitted fabric: a fabric knitted with a double-needle bed.

The single jersey or double jersey knitted fabric depends on the knitting method. In weft knitting, there are few weaving single jersey fabrics, and most of them are double jersey fabrics. In warp knitting, single-needle bed knitting is mostly used, and single jersey fabrics are mostly used.

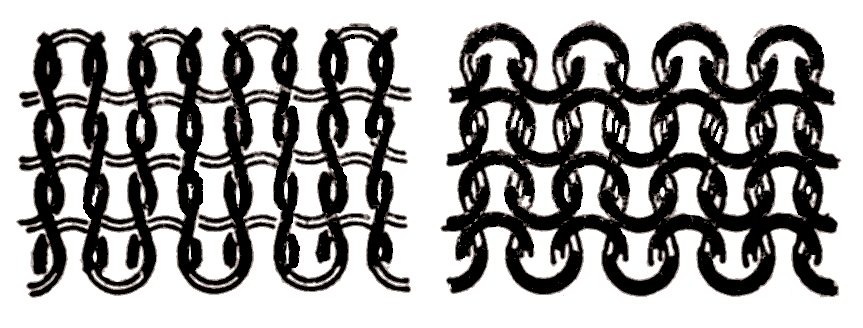

Figure 1-2 is the most basic weft knitting weave-weft flat stitch. This figure shows the front and the opposite of the flat stitch. Both sides are covered by loops of the same shape. The coil column of the surface layer with a V-shape on the top is called the front side, and the coil on the inner layer with the sinking arc on the top is called the backside. The vertical loops in the picture are called wales (W in the picture), and horizontal lines are called rows (C in the picture).

w1 w2 w3 w4 w1 w2 w3 w4

C3

C2

C1

C3

C2

C1

SINGLE JERSEY KNITTING MACHINE

DOUBLE JERSEY CIRCULAR KNITTING MACHINE

Figure 1-2 Weft flat stitch organization

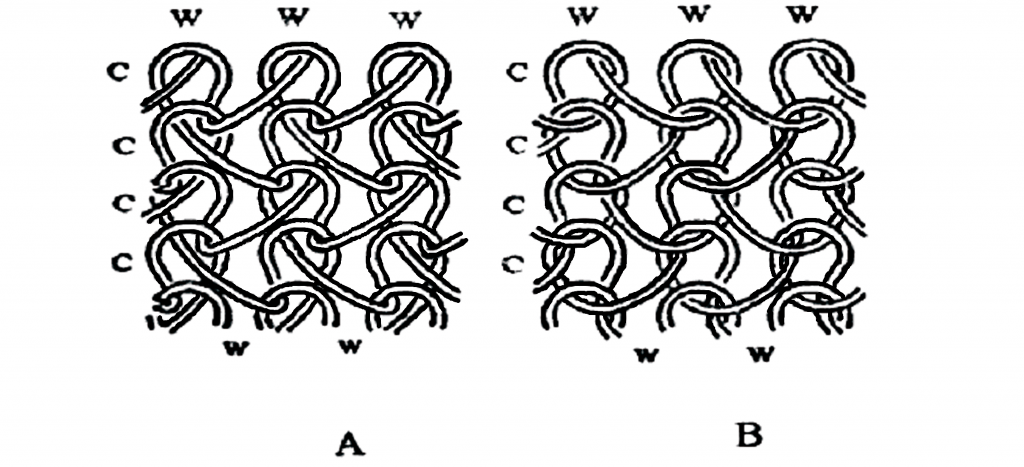

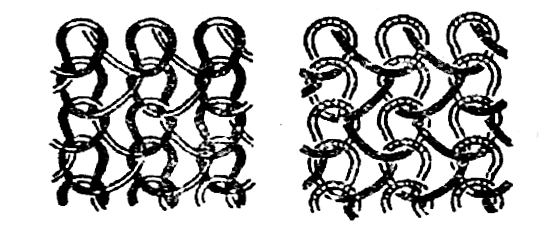

The coil shown in Figures 1-3 is the most basic meridian tissue. In the figure, A and B sinker arc coils have different shapes. A is an open coil, and B is a closed coil, both of which represent reverse coils. Figure 1-4 shows the front and back of the flat tissue (closed-loop). The front loop is the same as the weft knitting, which is V-shaped, and the arc of the sinking arc of the back loop becomes longer, forming a horizontally long V-shape.

Third, the characteristics of knitted fabrics

- Deformation recovery

Since the knitted fabric is made of loops, when subjected to external force, the looping column and the arc in the loop are transferred, that is, the loop is deformed. Under the condition of little external force, the fabric can produce greater deformation. When the external force disappears, the loop tries to return to its shape in the fabric processing. Low modulus and deformation recovery are the most significant characteristics of knitted fabrics. This feature makes knitted garments fit and comfortable when taken, especially weft knitted fabrics, which can expand and contract with the movement of various parts of the human body, giving people a comfortable feeling. - Softness

Due to the loop structure, the knitted fabric is porous and soft. Making underwear and sticking to the skin can give people a warm and soft texture. - Breathable and warm

The air permeability of knitted fabric is much greater than that of woven fabric. The porous structure is not only conducive to the discharge of sweat but also can hold more air and produce a heat preservation effect. - Dispersibility

When the yarn of the knitted fabric breaks or the loop loses the connection between the series and the loop, the loop and the loop will separate in a certain direction, which is called detachment.

Dispersibility is related to factors such as the type of raw materials used in the fabric, the friction coefficient of the yarn, the organizational structure, the underfill coefficient of the fabric, and the bending stiffness of the yarn. Single-sided weft flat stitches have greater dispersibility, but jacquard fabrics, double-sided fabrics, and warp knitted fabrics have less dispersibility or no dispersibility. - Crimping

The single jersey fabric will have a wrapping phenomenon at the edge in a free state, this phenomenon is called curling. This is caused by the internal stress of the curved line segment in the coil trying to straighten the line segment.

Hemming is related to factors such as the structure of the knitted fabric, yarn twist, organization density, and loop length. Generally, the hemming of single jersey fabric is more serious, and the tighter the density, the more serious the hemming, and the double-sided knitted fabric have no hemming. - Snagging and pilling

When the fabric encounters a hard object during use, the fibers or yarns in it will be hooked out. This phenomenon is called snagging. In the process of wearing and washing, the fabric is constantly rubbed, and the fiber ends on the surface of the yarn are exposed to the surface of the fabric. This phenomenon is called fluffing; when the fluffed fibers cannot fall off in time during subsequent wearing, they will be entangled and kneaded into many pieces. The small spherical particles are called pilling. Because of the loose structure of knitted fabrics, snagging, fuzzing, and pilling are more likely to occur than woven fabrics.

Related Product

high leg DOUBLE JERSEY OPEN WIDTH KNITTING MACHINE

HIGH-SPEED Small size RIB Circular KNITTING MACHINE

Double terry circular knitting machine

Velvet Shearing Circular Knitting Machine

High Speed Rib Knitting Machine

PILE LOOP SHEARING CIRCULAR KNITTING MACHINE

Related Article

What is heat-setting knowledge?

circular knitting machine guide

what is Basic knowledge of circular knitting

What is the Knowledge of knitted fabrics

what is the kind of circular knitting machine

Circular knitting machine basic operation knowledge

Read moreCircular knitting machine basic operation knowledge