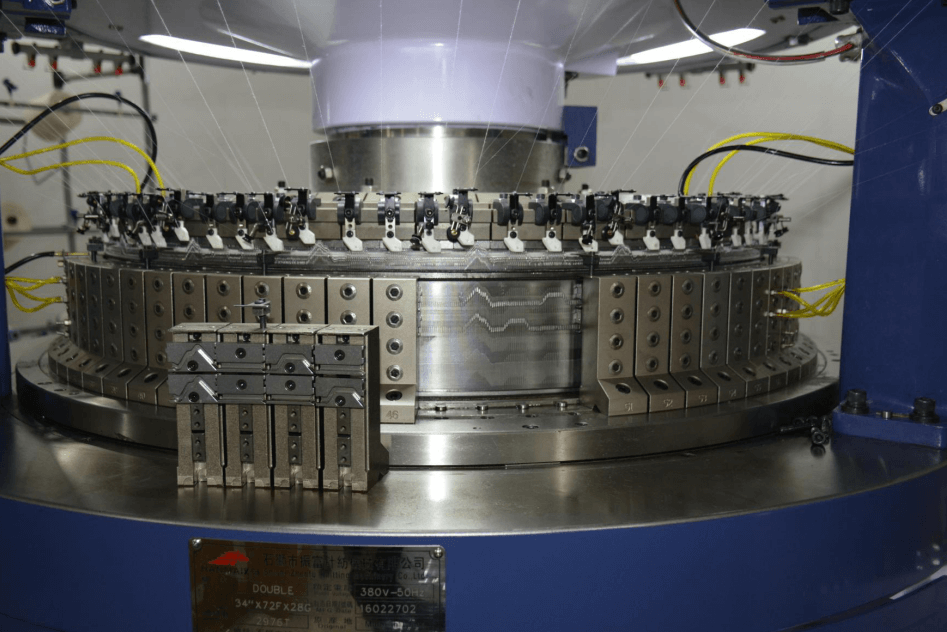

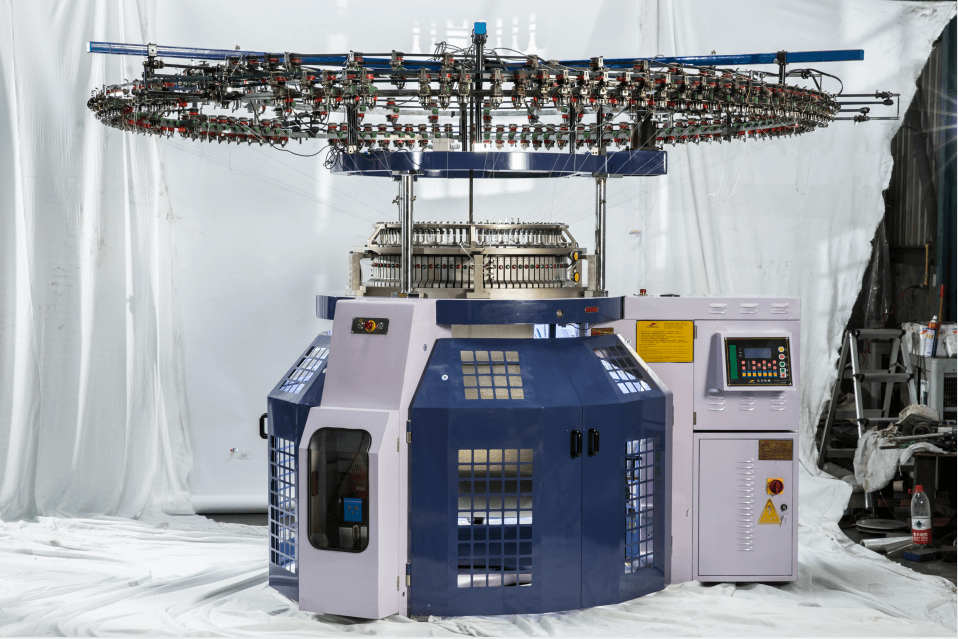

The common organizational structure of large circular knitting machines

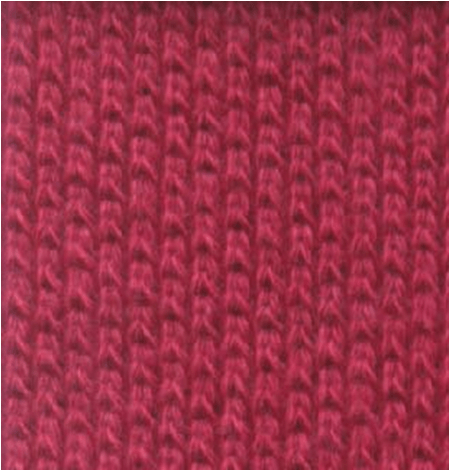

1) Weft flat stitch organization

The weft flat stitch structure is formed by successively stringing together the same kind of unit loops in one direction. The two sides of the weft flat stitch have different geometric shapes. The loop column on the front loop and the loop wales are arranged at a certain angle. The knots and neps on the yarn are easily blocked by the old loops and stay on the reverse side of the knitted fabric. , So the front is generally smoother and smoother. The arcs on the reverse side are arranged in the same direction as the course, which has a greater diffuse reflection effect on light and is therefore darker.

The cloth surface of the weft flat needle weave is smooth and clean, the texture is clear, the texture is fine, and the hand feels smooth. It has better extensibility in the transverse and longitudinal stretching, and the transverse extensibility is greater than the longitudinal extensibility. The hygroscopicity and air permeability are good, but there are dispersibility and curling properties, and sometimes the phenomenon of coil skew occurs. It is often used in the production of underwear and T-shirt fabrics.

2) Ribbed weave

The ribbed weave is made up of the coil’s wales and the back coil’s wales arranged alternately in a certain combination pattern. The front and back loops of the rib weave are not on the same plane, and the loops on each side are adjacent to each other. There are many types of rib weaves, depending on the configuration of the number of wales on the front and back coils. Usually, numbers are used to represent the combination of the number of wales on the front and back. Performance rib fabric.

The rib structure has good elasticity and extensibility both longitudinally and transversely, and the transverse extensibility is greater than the longitudinal direction. Ribbed weaves can only fall apart in the opposite direction of weaving. In the rib structure with the same number of wales on the front and back, such as 1+1 ribs, the crimping forces are balanced with each other, so there is no crimping phenomenon. It is commonly used in the production of close-fitting elastic underwear, casual clothing, swimming suits, and elastic parts such as necklines, trousers, and cuffs.

3) Double rib weave

A double rib weave, commonly known as a cotton wool weave, is composed of two rib weaves compounded with each other. Both sides of the double rib weave have frontal loops.

The extensibility and elasticity of the double rib weave are smaller than that of the rib weave. At the same time, it can only disperse in the reversible knitting direction. When an individual coil is broken, it is hindered by another rib structure coil, so the dispersibility is small, and the cloth surface is flat without curling. According to the knitting characteristics of the double rib structure, using different colored yarns and different methods on the machine can obtain a variety of color effects and various longitudinal uneven stripes. Commonly used in the production of underwear, sportswear, casual clothing fabrics, etc.

4) Adding yarn organization

Adding yarn structure is a structure in which a part or all of the loops of the pointer fabric are formed by two or more yarns. In general, two yarns are used for knitting. Therefore, when two yarns with different twist directions are used for knitting, the phenomenon of weft knitted fabric loop skew can be eliminated, and the thickness of the knitted fabric can be uniform. Weaving organizations can be divided into two categories: plain weaving and color weaving.

All the loops of the plain-colored spun yarn organization are formed by two or more yarns, where the veil is often on the front side of the fabric and the ground yarn is on the reverse side of the fabric. The front side reveals the circle column of the veil, and the backside shows the circular arc of the ground veil. The compactness of the plain-colored spliced yarn is larger than that of the flat needle weave, and the extensibility and dispersibility are smaller than that of the flat needle weave. Commonly used in the production of underwear, sportswear, casual clothing fabrics, etc.

5) Pad tissue

The padding structure is based on one or several padding yarns forming an unclosed overhang on some loops of the fabric according to a certain proportion, while the remaining loops are floating on the back of the fabric. The ground yarn weaves the ground weave of the pad organization, and the pad yarn is woven into an unclosed overhanging arc according to a certain rule on the ground weave, thereby forming the pad organization.

The padding tissue is mainly used to produce flannel, which is napped during the finishing process to make the padding yarn into a short pile shape and increase the warmth retention of the fabric. Commonly used in the production of fleece trousers, children’s wear, casual wear, T-shirts, etc.

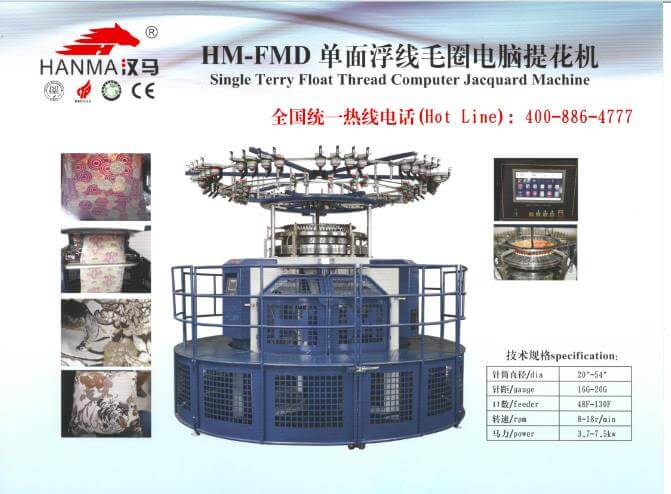

6) Terry tissue

The pile structure is a combination of flat stitches and pile loops with elongated sinking arcs. It is generally knitted with two yarns. One yarn weaves the ground weave, and the other yarn weaves loops with loops. Terry weaves can be divided into two types: normal terry weaves and colorful terry weaves, and single-sided and double-sided. In the ordinary pile structure, the sinking arc of each pile loop forms a pile. In the pattern pile structure, the pile is formed in a part of the loop according to the pattern. The single-sided loop structure only forms loops on the reverse side of the fabric process, while the double-sided loop structure forms loops on both the front and back sides of the fabric.

The looped tissue has good warmth retention and moisture absorption, and the product is soft. thick. It is suitable for the production of pajamas and bathrobe fabrics.

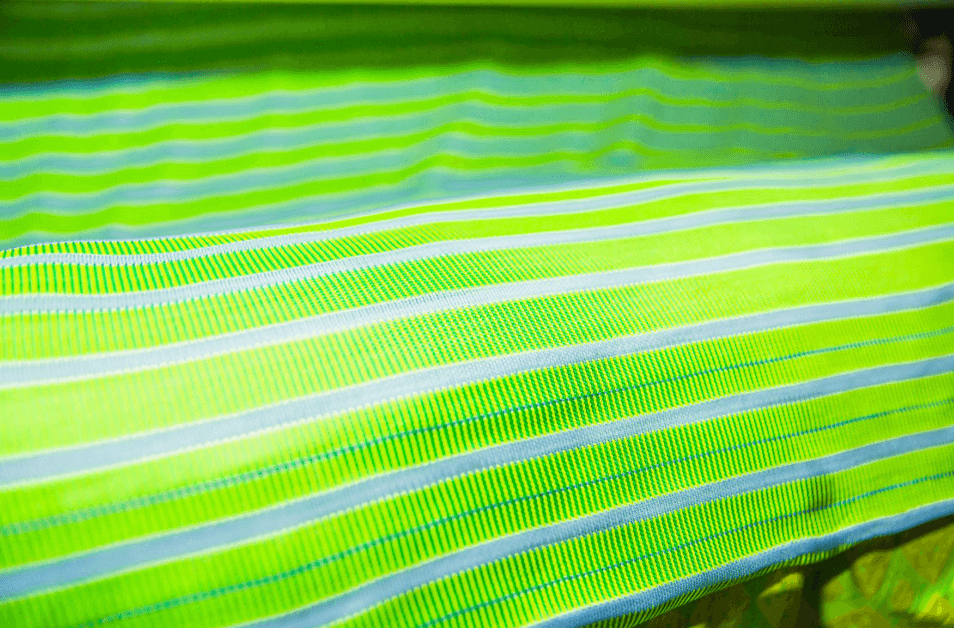

7) Color horizontal striped fabric

The horizontal stripe effect is formed by using different types of yarns to form each course.

The color horizontal stripe effect is formed by dyeing after interweaving colored yarns or yarns of different properties. The basic organization can be used or combined with the pattern organization, and its performance is the same as the user organization.

Make use of changes in the structure of the organization, such as the use of ribs or double ribs to compound with a single-sided structure or with a tuck structure. Can form horizontal uneven stripe effect on the surface of the fabric. The common fabrics of the former are ribbed air layer weaves and ribbed tuck weaves. These weaves are less stretchable than ribbed weaves. They are soft, elastic, dimensional stability, and thick and firm. The fabric has a wide width and is widely used. For knitted outerwear, children’s clothing, sportswear. The latter common fabrics include double rib air layer weaves and double rib tuck weaves. Compared with double rib fabrics and ribbed composite weave fabrics, these weaves are thicker, tighter, less transverse extensibility, good elasticity, and dimensional stability. The characteristics of this product are widely used in the production of acupuncture coats.

In addition to the above-mentioned organizations, there are single-sided tuck weaves, double-sided terry weaves, terry weaves, weft inserted weaves, yarn-added weaves, padding weaves, etc. which can form horizontal stripes on the fabric

8) Fabrics with vertical stripe effect

The vertical stripe effect is mainly formed by the method of organizational structure changes.

For outerwear fabrics, there are tuck stitches, ribbed composite weaves, double ribbed composite weaves, padding weaves, etc. to form fabrics with a vertical stripe effect. The longitudinal stripe effect formed by the tuck organization is suitable for making spring and autumn sweater fabrics; the use of rib stitching and floating stitching, rib tucking and floating stitching, etc. can form a longitudinal uneven stripe effect on the surface of the fabric, and the horizontal extensibility of the ribbing stitching and floating stitching structure Small size, good dimensional stability, suitable for making sports casual wear, spring and autumn outerwear, etc.; the use of fat flower structure can form longitudinal uneven stripe effect on the surface of the fabric. The appearance of the fat flower structure is like corduroy. It is usually woven with polyester low-elastic yarn. Making autumn and winter outerwear, but the fabric is easy to fuzz, pilling and snagging, and due to the uneven loop structure, the strength of the fabric is reduced.

In addition, the use of jacquard weave, terry weave, and yarn weaving can all form a vertical stripe effect on the fabric.

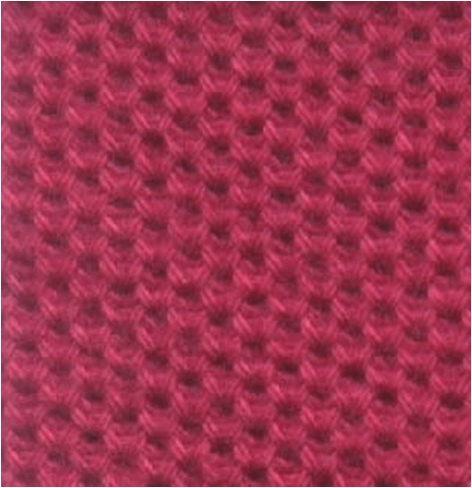

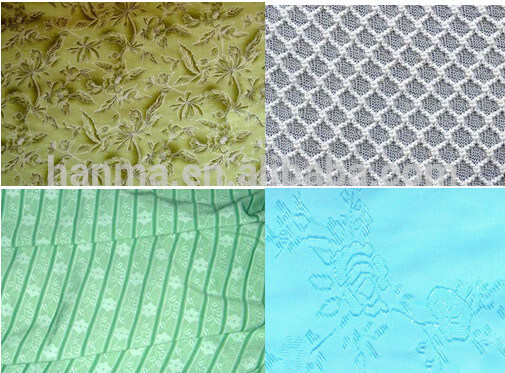

9) Mesh fabric

The mesh effect fabric is the most widely used fabric for T-shirts and spring and autumn outerwear.

The use of coils and tuck ring suspension arcs staggered configuration, forming a mesh effect, also known as piqué fabric. According to the same or an unequal number of flat stitches and tuck loops, but the same way, alternate checkers configuration to form a variety of piqué fabrics. This kind of fabric has good air permeability. It is a double-bead fabric woven with combed cotton yarn. After post-treatment, the mesh is crystal clear and resembles pearls. It is an excellent fabric for summer, spring and autumn clothing. Tuck and float are knitted on the basis of the rib structure to form a badger-shaped concave-convex mesh effect. This kind of fabric has good air permeability and small longitudinal and horizontal extensibility. It is a good fabric for summer, spring and autumn outerwear. The double rib weave and tuck weave are combined to form a honeycomb mesh on the surface of the fabric. This kind of fabric is thicker than the rib tuck, has less extensibility, is stiff, has bones, and has good dimensional stability. It is a good fabric for casual fashion in spring and autumn. Sweat-absorbent and quick-drying fabrics often use this structure.

10) Jacquard weave

Jacquard weave is to knit the yarn into loops by placing the yarn pads on some needles selected according to the pattern requirements. The knitting needles that do not put the new yarn into the loops do not form a loop, and the yarn forms a floating thread, which is behind these knitting needles that do not participate in the knitting. . Jacquard fabrics are divided into single-sided jacquard fabrics and double-sided jacquard fabrics according to the organizational structure, and plain jacquard fabrics and multi-color jacquard fabrics according to the color. There are also jacquard terry knitted fabrics, jacquard rib knitted fabrics, and so on. The raw materials are low-elastic polyester yarn, nylon elastic yarn, nylon filament, eye-lens yarn, wool yarn, cotton yarn, and polyester-cotton blended yarn. Jacquard knitted fabric has clear patterns, rich patterns, thick texture, stable structure, less extensibility and dispersibility, soft and elasticity, and is a good knitted outerwear fabric.

11) Composite organization

The composite structure is composed of two or more fabric structures. It can be composed of different basic organizations, different change organizations, and different color organizations. The compound organization can be compounded into the required organization structure according to the characteristics of various organizations. Rib weave and plain needle weave are compounded to form rib air layer weave, and double rib weave and flat needle weave are compounded to form double rib air layer weave. The fabric of this kind of organization is compact and thick, has good elasticity, good warmth retention, small lateral extensibility, and good dimensional stability. If the outer layer of the air layer is knitted with cotton yarn and lined with high-stretch silk, it is an excellent fabric for thermal underwear; if the front and back sides are knitted with different types of yarn, it is especially suitable for outerwear. Incomplete ribs and plain stitches are compounded to form a dotted weave, with a compact structure and stable dimensions. The surface of the fabric has an obvious dotted effect. The jacquard weave is combined with the tuck weave to form a jacquard tuck weave. The front and back sides can be woven with different types of yarns. The front side and the backside can be knitted with obvious color effects, the surface is wear-resistant, and the backside is soft and hygroscopic. It is an excellent fabric for knitted outerwear. The polyester-covered cotton fabric interwoven by two raw materials has silk (polyester and other chemical fibers) exposed on the front, but cotton (cotton and other natural fibers). It has a crisp appearance, wrinkle resistance, abrasion resistance, fastness, and good colorfastness. The inner layer is soft. Moisture absorption, breathability, warmth, low static electricity, comfortable to wear, combining the advantages of polyester (chemical fiber) knitted fabrics and cotton knitted fabrics. Single-sided polyester-covered cotton fabrics are made of plain stitch yarn, and double-sided polyester-covered cotton fabrics often use ribs, double-ribbed tuck floats, or air layer structures, which are suitable for making sportswear, jackets, fitness pants, etc.

12) Fleece cloth

Fleece knitted fabric (fleece): The knitted fabric covered with a dense layer of short and fine fleece is called fleece knitted fabric, which is divided into single-sided fleece and double-sided fleece. A single-faced pile is formed by napping the backside of the pad structure, and a double-faced pile is generally formed by raising and finishing both sides of a double-sided knitted fabric. After bleaching and dyeing, the pile knitted fabric can be processed into bleached, extra white, plain, printed, and other varieties. It can also be woven into plain or yarn-dyed products with dyed or mixed yarn.

The fleece knitted fabric is soft to the touch, rich in texture, light and warm, and has a strong sense of comfort. There are many types of raw materials used. The base fabric is commonly used in cotton, polyester-cotton blended yarn, polyester yarn weaving, and thicker, low-twist cotton yarn, acrylic yarn, woolen yarn, or blended yarn is used for pile yarn. According to the linear density of the yarn used and the thickness of the pile surface, single-sided fleece is divided into a fine pile, thin pile, and thick pile. The suede surface of the fine flannel cloth is thin, and the cloth surface is fine and clean, and beautiful. The dry weight of pure cotton flannel is about 270g/m2, which is often used to make underwear for women and children; the dry weight of acrylic flannel is 220g/m2, which can be made into sportswear and outerwear. The purified fiber in the thin flannel has bright color, low shrinkage, and dry weight of 380~450g/m2. It is used to make spring and autumn sweaters and trousers. The dry weight of thick flannel is 545~570g/m2, which is relatively heavy, has a fluffy suede, and has better warmth retention. There are pure cotton and acrylic products, which are mostly used to make winter sweaters and trousers.

13) Cut flannel

The weft-knitted single-sided terry cloth is cut down by cutting the pile of the pile, and then brushed and ironed to form a smooth suede. The suede is fine and shiny, also known as velvet. The structure of the shearing fabric is generally made of chemical fiber, and the fleece yarn is made of combed cotton, acrylic polyester, and so on. Various patterns and colors of velvet can be formed by using jacquard or color strips, flower scissors, and flower ironing.

14) Plush tissue

The plush organization is the organization that uses fiber strips or yarns and ground yarns to feed into the weaving loops during the weaving process. The fibers are attached to the back of the fabric in the form of fluff. It is woven with various synthetic fibers of different properties. The appearance is similar to natural fur, so it is also called “artificial fur”. Especially knitted artificial fur made of acrylic fiber is lighter than natural fur, has good warmth retention and abrasion resistance, and the pile structure and shape are similar to natural fur. Realistic appearance, suitable for making winter outerwear.

The pattern structure can not only form various patterns on the knitted grey fabric to beautify the appearance of the knitted fabric, but also change the performance of the knitted fabric, such as reducing the dispersibility, making the fabric tighter, thicker, and having good dimensional stability. Appreciation provides abundant materials.