Synthetic fibers differ from natural fibers in that they possess unique properties based on their molecular composition, such as high strength, lightweight, quick-drying, elasticity, and resistance to mildew and mold. Their use in the textile industry is gradually surpassing that of natural fibers. Polyester, a major category of synthetic fibers, has rapidly gained traction since its development in 1941. In recent years, its market share has gradually surpassed that of polyamide fibers, becoming the leading synthetic fiber. While PET, PBT, and PTT fibers are all polyester fibers, their properties differ, resulting in varying applications.

01PET fiber

PET fiber, also known as polyethylene terephthalate fiber, is commonly referred to as polyester in my country. Currently, PET fiber is primarily produced through the direct esterification of terephthalic acid (PTA) and ethylene glycol (EG) or the transesterification of dimethyl terephthalate (DMT) and ethylene glycol (EG).

The longitudinal cross-section of PET fiber is similar to that of PTT fiber, appearing circular under a microscope. Its thickness is relatively uniform, with minimal hairiness and a smooth surface. The molecular formula of PET fiber is [-OC-Ph-COOCH2CH2O-]n, where the monomeric group consists of a benzene ring, two ester groups, and two methylene groups. Due to the presence of benzene rings in the PET molecule, stretching is required after traditional melt spinning to promote rapid crystallization. This results in a high degree of fiber orientation and crystallinity. The resulting PET fiber exhibits high strength, good elasticity, excellent heat setting properties, excellent heat resistance, and resistance to acids and alkalis.

Due to its ease of processing and affordability, polyester is widely used in clothing, decoration, and industrial applications. In the clothing sector, PET fabrics are easy to wash and dry quickly, earning them the nickname “wash and wear.” The ester bonds in its molecules offer strong antioxidant properties, making them resistant to degradation by detergents and soaps. PET fibers are also resistant to microbial attack, resulting in excellent wear resistance. After heat setting, polyester fabrics exhibit stable dimensions, excellent stiffness, and are resistant to shrinkage. They are used in shirts, men’s trousers, outerwear, and jackets. However, polyester’s drawbacks stem from its dense molecular arrangement and lack of hydrophilic groups, resulting in poor dyeability, hygroscopicity, and antistatic properties, as well as flammability.

With the advancement of science and technology and the consumer’s pursuit of high-quality clothing, the multifunctional applications of PET fiber are currently a key research area. In order to improve the shortcomings of polyester fiber, such as poor moisture absorption and easy generation of static electricity, Li Fang used nano-TiO2 to modify the surface of polyester fiber. While improving the defects of polyester itself, the addition of TiO2 gave it antibacterial, UV resistance, photocatalytic self-cleaning and other properties; Shi Zheng used chemical modification methods such as metal ions and organic acids to develop antibacterial PET fiber; Sun Pengxiao studied the surface modification and weaving methods of PET fiber used in medical artificial ligament materials.

02PBT fiber

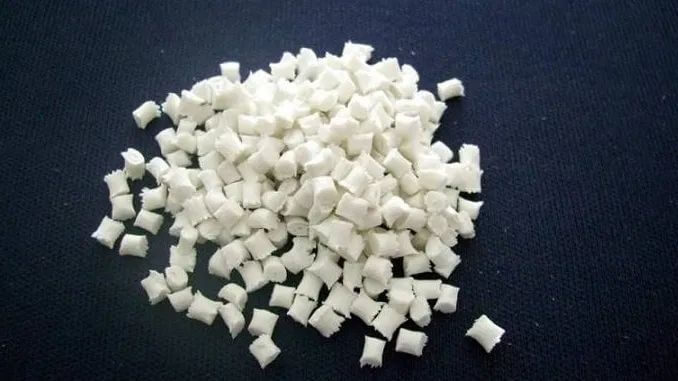

Polybutylene terephthalate (PBT) is made by esterifying dimethyl terephthalate (DMT) or terephthalic acid (TPA) with butanediol and then polycondensing it. Due to the abundant raw materials and similar production process to polyester, PBT fiber has been produced on a large scale in recent years. PBT’s molecular formula is [(CH2)4OOCC6H4COO]n. It has two more methylene chains than PET. The larger methylene chains in PBT form a helical main chain structure, similar to the molecular structure of nylon. However, the methylene chains are longer than those in PET. Therefore, PBT fiber has similar softness, abrasion resistance, and elasticity to nylon, and its chemical properties are similar to those of PET. Because PBT fiber molecules can move freely, they possess excellent tensile and compressive elasticity and wrinkle resistance. Compared with the poor dyeability of PET, the glass transition temperature of PBT is only 22°C. It can be boil-dyed with disperse dyes at normal pressure without a carrier. However, due to the existence of type a and type B crystal deformation, PBT has poor dimensional stability at high temperatures.

Due to its excellent resilience, mildew and moth resistance, good curl elasticity, antistatic properties, and dyeability, PBT fiber is widely used in stretchable clothing such as swimsuits, sportswear, ski suits, jumpsuits, and dance leotards. Spandex is expensive and has poor lightfastness, easily yellowing. However, PBT fiber’s elasticity is second only to spandex and superior to nylon, making it a viable alternative to spandex in certain fabrics. For example, spandex is commonly used as the stretch yarn in stretch jeans. However, spandex has low strength and is prone to breakage after prolonged wear and friction. Using PBT fiber instead of spandex as the stretch yarn can effectively improve this situation. Due to its wool-like feel, PBT fiber can be interwoven with cotton and linen in the wool spinning industry for autumn and winter clothing. It is also an ideal down-like feather and filling material.

In addition to its use as a textile material alone, PBT fiber has also been extensively researched and developed in recent years for its modified applications. For example, PBT/PET composite spinning fiber not only has good spinnability, but also has a soft feel, high loft, and is easy to dye. It can be used as wool-like fiber and can also replace spandex. At present, the elasticity of PBT block copolymer fiber can reach 80% of spandex, and its other properties are better than spandex. At the same time, the appearance of this fiber is very similar to real silk and can be interwoven with real silk to form special style fabrics.

03 PTT fiber

PTT fiber (polytrimethylene terephthalate) is a new polyester fiber developed by Shell in the mid-1990s. PTT can be produced by melt polycondensation of 1,3-propylene glycol (PDO) and dimethyl terephthalate (DMT) via transesterification, or by melt polycondensation of PDO and terephthalic acid (PTA). PTT fiber is a semi-crystalline thermoplastic polyester with a smooth, rounded surface. Unlike PBT and PET fibers, PTT fiber possesses a trans-para-para-trans conformation, which minimizes energy and creates a distinct “Z” shape. Furthermore, while PET and PBT have two methylene units in their molecular chains, PTT has three. This creates an “odd carbon effect” between the molecular chains. This molecular structure gives PTT fiber the deformability of a coiled spring and superior resilience compared to PET and PBT. As a new synthetic fiber, polytrimethylene terephthalate (PTT) fiber has been dubbed the “new polyester fiber of the 21st century” due to its excellent dimensional stability, stain and wrinkle resistance, abrasion resistance, and dyeability, coupled with the high resilience derived from its unique molecular chain structure.

As a new material, PTT fiber combines the advantages of PET and PBT fibers while also overcoming some of their shortcomings.

Currently, most swimwear on the market is made of nylon fabric, but nylon’s low light and chlorine resistance limits its use in swimwear. A comparison of the elasticity of nylon and PET reveals that PTT fabrics offer superior elasticity, meeting swimwear requirements for elasticity, sizing, and comfort. Furthermore, PTT’s ease of dyeing, high color fastness, chlorine resistance, and UV resistance make it an ideal material for swimwear. PTT/wool blends not only address wool production issues but also offer a rich feel and excellent drape, combining the multiple properties of nylon and spandex. Given PTT fabric’s ease of shaping and wrinkle recovery, its application as shape-memory fabrics is also growing. PTT fiber nonwovens can be used in carpet backing, artificial leather, protective materials, and medical applications. Their soft feel and excellent drape also hold great potential for applications in sanitary napkins and disposable diapers.

Conclusion

PBT, PET, and PTT fibers hold broad prospects in the textile industry. With technological advancements and increasing demand for comfort and versatility in clothing, developing new multifunctional, composite fibers is a key area of focus. As synthetic fibers, efficient, low-carbon, and environmentally friendly production is key to process improvement, while fabric recycling also holds potential market value.

Related Article

Rare earth heating fibers

Textile fabric width control

Several types of regenerated fibers that are easily confused.

Read moreSeveral types of regenerated fibers that are easily confused.

Key technologies for double-sided circular knitting machine needle plate calibration

Read moreKey technologies for double-sided circular knitting machine needle plate calibration

How a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)

Read moreHow a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)