What is woolen and worsted?

Woolen cashmere and worsted cashmere, in short, are two kinds of yarns with different thicknesses in appearance due to different technological processes in the process of spinning cashmere into yarn.

In the spinning process, there is a process called combing, and the yarn produced by this process is called combed yarn, but the yarn produced by this process is called combed yarn or roving yarn. Combed yarn is better than combed yarn in strength, evenness, and so on.

What is the difference between the weaving effect of woolen and worsted?

Woolen cashmere products have the knitting effect of stick needles. The pile surface is rich and flat, the color is uniform and slightly shiny, the hand touch has a warm feeling, there is no crease after folding and pressing, and the wool is soft and has strong resilience.

Worsted cashmere products have a smooth and smooth surface and fine and clear texture. Soft and natural luster, soft and elastic feel.

Analysis of worsted, semi-worsted and woolen

The biggest difference between semi-worsted and traditional wool worsted and woolen processes is that it integrates cotton spinning technology and wool spinning technology to form a new multi-component mixing process, which is preceded by woolen and woolen equipment plus cotton carding machine, drawing frame, roving machine, and spinning machine; The backtrack is worsted winding, doubling and double-twisting equipment. The change of equipment and technology has solved the problems that the original wool spinning equipment can not solve.

Semi worsted can realize the successful blending of natural raw materials such as cotton, wool, silk, and hemp with other new man-made fibers and chemical fibers. The raw materials of wool semi-worsted include natural fibers such as cashmere, wool, silk, rabbit hair, cotton, and ramie, artificial fibers such as soybean protein fiber, milk protein fiber, Tencel, modal, bamboo fiber, and viscose fiber, as well as chemical fibers such as acrylic fiber, polyester fiber, and nylon. The product structure is extremely rich.

Roving is a spinning method of wool spinning. The spun cashmere is a kind of Coarse Count, and the price is low. The wool yarn has poor properties, easy pilling, and deformation. The count of semi-worsted is about 28 / 2. Compared with woolen, the price is higher and the nature is better. Worsted cashmere is the best. The count is more than 2 / 48. The articles made are soft and delicate. Very comfortable and warm. But this kind of yarn is very expensive, commonly known as “soft gold in wool yarn”. About 1800 yuan / kg.

There are two kinds of cashmere high count yarn production lines in China, semi-worsted spinning and full worsted spinning. Semi worsted yarn can be spun below 16.67 texes without combing to remove short fibers, which can meet the needs of general light and thin fabrics, with high yarn yield and relatively low cost. The worsted yarn needs to be combed to remove short fibers, and the spinning count can reach 10Tex, but the cost is high. Due to the problem of yarn strength, it often needs to be blended with other fibers, which is suitable for special light and thin fabrics. Therefore, the development and production of semi-worsted cashmere yarn, after woolen cashmere yarn, has been paid more and more attention by the cashmere yarn market at home and abroad.

The difference between woolen and worsted

Identification of woolen fabrics:

(1) Sensory recognition. All pure wool products generally have a rich and flat pile surface, uniform color and luster, warm touch, no crease after folding and pressing, and the wool body is soft and elastic.

(2) Combustion identification. When smoking a single yarn and burning it with fire, it will smoke slowly. It smells like burning hair. The gray is black and brittle.

(3) Product number identification. Every piece of wool sold is labeled with a five-digit product number. If the first digit is 0, it is pure wool and the first digit is 1, it is blended products. For example 01001 – pure wool Melden; 11001 – blended Melton; 71001 – purified fiber Melden.

Identification of worsted:

Worsted wool is a high-grade garment fabric mainly made of pure cotton wool, which can also be mixed with a certain proportion of wool chemical fiber or other natural fibers, processed by combing equipment and technology, and made through combing, merging, drafting, spinning, weaving, dyeing and finishing for many times. It has good elasticity, softness, unique cashmere shrinkage, and wrinkle resistance unique to animal hair. It also has warmth retention after absorbing moisture or sweat.

Difference between woolen and worsted wool:

The worsted fabric has a smooth and smooth surface and fine and clear texture. The luster is soft and natural, and the color is pure. Feel soft and elastic. Pinch the Tweed with your hand and loosen it. The crease is not obvious and can be quickly restored to its original state. The yarn count is mostly double strand.

Woolen cloth is plump, compact, and thick. There is fine fluff on the surface, and the texture is generally not exposed. Feel warm, plump, and elastic. The yarn is mostly coarse single yarn.

The difference between worsted, semi-worsted and woolen lies in the thickness of yarn count,

There are no special provisions on the composition.

- Worsted wool, also known as combed wool, is woven from high count combed wool yarn. The wool quality is good, the fabric is clean, compact, flat and soft, the fabric is clear, bright and elastic, and its varieties include gabardine, serge, tribute, Valentine, Paris, breeches, women’s clothing, camel silk cotton, Vienna, etc.

- Woolen cloth, also known as combed woolen cloth, is woven from combed yarn or part of combed woolen yarn. The body of the cloth is thick, and there is a layer of plush on the surface of the fabric to cover the number of lines of the organization. However, there are also thick woolen yarn without Plush on the surface to form various colors and patterns. This kind of products feel soft, soft and warm. The main varieties are plain coat, silver gun coat, mohair coat, Melden, tweed, uniform, plush, camel hair, etc.

- Semi worsted cotton includes: plain cotton, semi refined cotton (semi worsted), refined cotton (worsted). The biggest difference between semi worsted and traditional wool worsted and woolen process is that it integrates cotton spinning technology and wool spinning technology to form a new multi-component mixing process.

- The so-called worsted and woolen spinning should be explained from two angles: one is on the fiber, the other is the weaving method. The general worsted spinning on the fiber is 32 and 40. The higher the number of high-line fibers, the smoother the fibers, fewer joints, high natural density, good wear resistance and comfort. The other is the weaving method. The worsted weaving machine is used for worsted fabrics to prevent fiber breakage, High density, woolen fabrics have many joints, which are easy to break, poor natural wear resistance and poor density.

- Worsted spinning is to use high-quality cotton raw materials to spin yarn with high twist and less hairiness (generally single strand yarn and combined strand yarn). Worsted products have light and thin feel, dense grain, good wet fastness and wear resistance, so the price is also higher.

- The difference between semi worsted yarn and worsted yarn is mainly in and production technology. Worsted yarn has one more combing preparation and combing process than ordinary yarn. Semi worsted yarn is made by mixing worsted green strip and common spinning green strip. It is commonly known as semi worsted. It is slightly better than common combed yarn and slightly less than worsted yarn. Combed wool yarn has the characteristics of smooth surface, elasticity and good strength. It is used to weave serge, tweed, Valentine and other fabrics.

Semi worsted yarn does not have the above characteristics. - What does wool spinning mean by worsted, semi worsted and woolen, and what are the differences between them?

(1) Carding wool spinning

It is a wool spinning process in which the net wool is loosened, combed, divided into narrow strips, twisted and spun directly. It includes the processes of mixing and oiling, carding, strip rubbing and twisting into roving, and then drafting and twisting into oil yarn. The spun yarn has good hairiness, soft feel and low count. It is used for weaving woolen fabrics.

(2) Combed wool spinning

After the washed wool is combed into strips, it is made into combed tops after combing and the preparation and finishing process before and after combing, and then spun into yarn, which is for combed wool spinning. This process includes carding, slitting, combing, slitting and re washing, slitting, roving, spinning and other processes. It is mainly divided into two stages: sliver making and spinning. Internationally, combed top is a commodity, so the enterprise producing combed top is often called top factory. Combed wool yarn has the characteristics of smooth surface, elasticity and good strength. It is used to weave serge, tweed, Valentine, whatever flavor tweed and other fabrics.

(3) Semi combed wool spinning

Similar to combed wool, but not combed, prepared and finished. The process flow is as follows: (wool cleaning) → mixing and oiling → carding → needle carding (3 passes) → roving → spinning. It has the characteristics of short process and low cost, but the yarn quality is slightly worse than combed yarn. It is suitable for spinning low count (2 ~ 12 metric count) yarn and medium count (30 ~ 40 metric count) yarn. Most of the products are manual knitting yarn, knitting yarn, carpet yarn, industrial and decorative fabric yarn, etc. it can also be used to weave general clothing materials.

Related Product

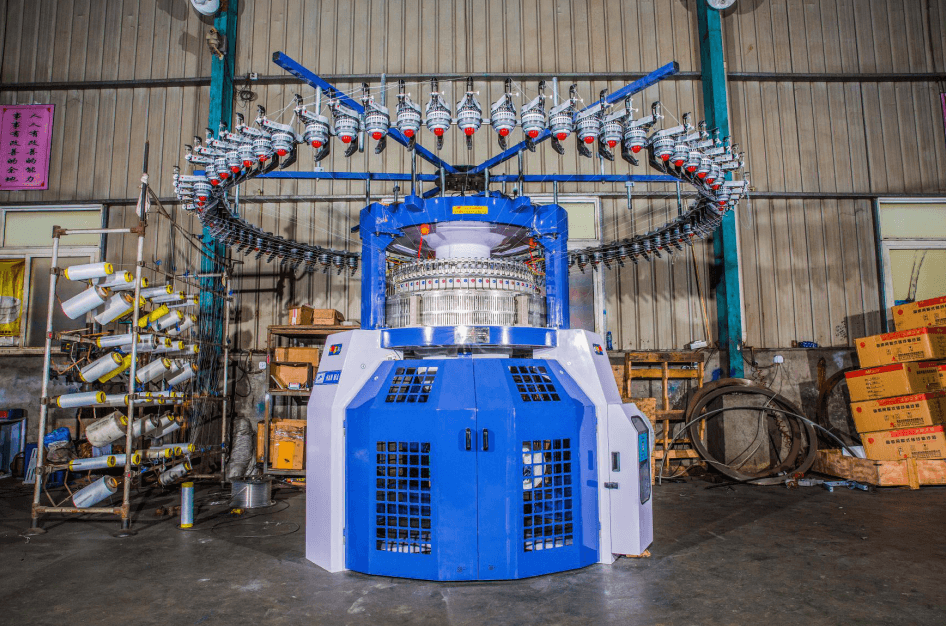

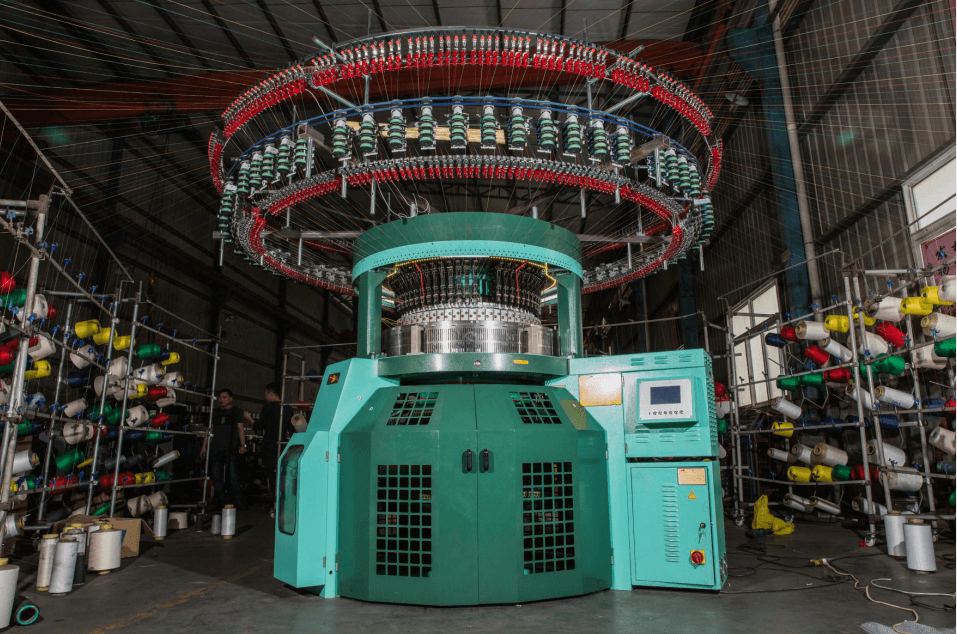

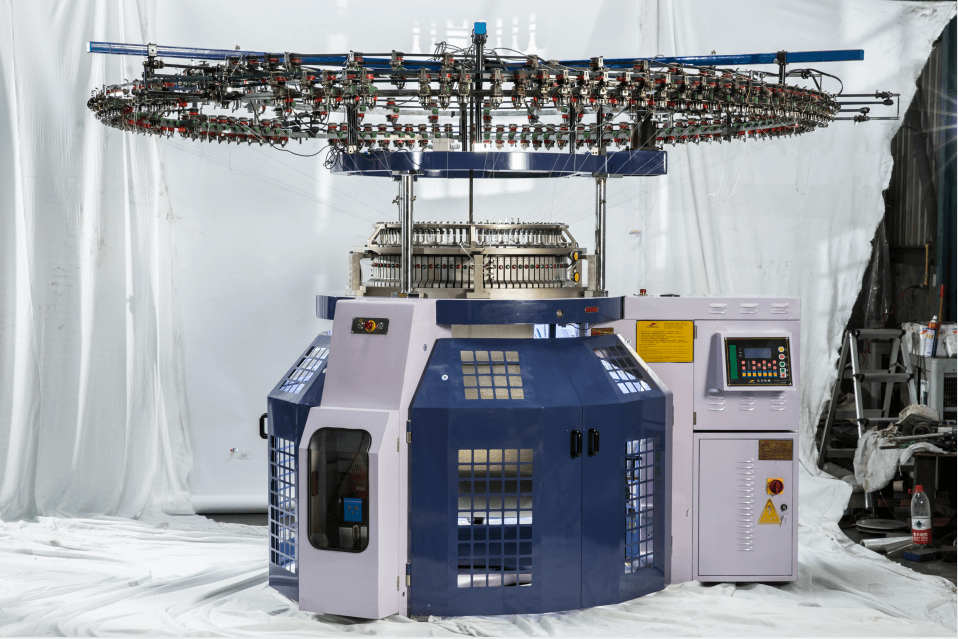

Double terry circular knitting machine

DOUBLE RIB JACQUARD CIRCULAR KNITTING MACHINE

DOUBLE JERSEY AUTO-STRIPER CIRCULAR KNITTING MACHINE (FOUR/SIX COLORS)

PILE LOOP SHEARING CIRCULAR KNITTING MACHINE

High speed three thread fleece circular knitting machine

DOUBLE JERSEY OPEN WIDTH KNITTING MACHINE

Related Article

Rare earth heating fibers

Textile fabric width control

Several types of regenerated fibers that are easily confused.

Read moreSeveral types of regenerated fibers that are easily confused.

Key technologies for double-sided circular knitting machine needle plate calibration

Read moreKey technologies for double-sided circular knitting machine needle plate calibration

How a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)

Read moreHow a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)