Readers’ questions:

When adjusting the machine, how to adjust the roundness and flatness of needle cylinder and needle disc? What should we pay attention to when adjusting?

Expert answer:

The operation process of the circular machine is essentially a movement process dominated by the circumferential rotation of parts. Most parts are installed and operated around the same center. After a certain period of operation, the machines in the knitting factory need to be overhauled. In addition to cleaning the machines and replacing the worn parts, the main work of the overhaul process is to check whether the installation accuracy and operation accuracy of each part have changed. If there are changes and exceed the accuracy requirements, they should be corrected.

The following is an analysis of the reasons why the roundness and flatness of needle cylinder, needle disc and other parts can not reach the required range.

Influencing factors when the roundness of needle cylinder can not meet the standard

1.1 the operation of the toothed disc cannot reach the required accuracy

For example, the wear of the positioning stop between the large disc and the toothed disc (mostly in the wear-resistant plate operation mode) leads to the loosening of the toothed disc or the wear and loosening of the steel wire runway (mostly in the steel wire runway operation mode), and the wear and loosening of the bearing in the central sleeve of the double-sided machine tripod can lead to the failure of the roundness of the needle cylinder to meet the required accuracy. The inspection method is as follows: keep the machine at a standstill, push the dial indicator head on a certain point of the tooth disc needle disc holder (if the fixing screw between the needle cylinder or needle disc and the toothed disc or needle disc holder is not loosened, the top of the gauge head can also be on a certain point of the needle cylinder or needle disc), and the gauge base is sucked on a machine part that does not operate with the toothed disc or needle disc trays, such as large disc and tripod, as shown in Figure 1 As shown in Figure 2. Push and pull the toothed disc or needle disc tray with force, and observe the change range of the dial indicator pointer. If it is less than 0.01mm, it proves that the operation accuracy of the toothed disc is very good; When it is greater than 0.01mm and less than 0.03mm, the accuracy is better; When it is greater than 0.03mm and less than 0.05mm, the accuracy is general; When it is greater than 0.05mm, the operation accuracy of the toothed disc is poor. At this time, it is difficult or impossible to adjust the roundness of the needle disc to within 0.05mm. Be sure to restore the operation accuracy of the tooth disc or tray first. The method of restoring the operation accuracy depends on the different operation structures and modes of the dental disc, which will not be described in this paper.

1.2 the end face of the toothed disc in contact with the needle cylinder is uneven or the indirect contact surface of the needle disc and the bracket is uneven

When the contact surface is uneven, after the tightening and fixing of the fastening screws, the gap between the needle cylinder, needle disc, tooth disc, and bracket will be forcibly pressed and pasted, resulting in inelastic deformation of the needle cylinder and needle disc. Therefore, the roundness will change beyond the required range. In terms of practical operation, if the toothed disc is rotated slowly when the fastening screw is loosened, the roundness of the needle cylinder and needle disc can be easily adjusted to within 0.05mm, but when the roundness is checked after locking the screw, it greatly exceeds the required range within 0.05mm. The steps to solve this problem are as follows:

a. Loosen the fastening screw and roughly round the needle cylinder and needle disc to less than 0.03 mm.

b. Release the gauge head, place the dial indicator head on the end face of the needle cylinder mouth or the end face of the needle disc, move the fastening screw one by one to the lower part of the gauge head, lock the screw, and observe the change of the gauge needle. If the reading becomes smaller, it proves that there is a gap between the needle cylinder, needle disc, and tooth disc or bracket.

c. When the pointer of the watch changes, pad the gasket with an appropriate thickness on both sides of the fastening screw, lock the screw and then observe the change of the watch needle until the change of the watch needle after adjusting the locking screw is less than 0.01mm, preferably no change. Turn to the next fastening screw and repeat the above process until the change of the watch needle is less than 0.01mm after each fastening screw is locked, that is, there is no gap at the fastening screw between the needle cylinder, needle disc, and tooth disc or bracket. It should be noted that after the adjustment of each screw position is completed, loosen the screw before entering the next screw to ensure that the needle cylinder and needle disc are always in a relaxed state during the adjustment process.

d. Check the flatness of the whole circle of the needle cylinder and needle disc. If the change of the gauge needle exceeds 0.05mm, pad in the gasket to adjust it to less than 0.05mm.

e. Loosen the dial indicator head and place it on the side of the needle cylinder or at the disc opening of the needle disc. Adjust the roundness change of the needle cylinder and needle disc to be less than 0.05mm, and lock the screws.

The above process comes down to one sentence: first pad, then level, and then round.

1.3 the roundness of the needle cylinder cannot reach the required range due to its own defects

The method to judge the defects of the needle barrel or needle disc is actually very simple. First, operate according to the steps described in parts 1.1 and 1.2 to eliminate the interference factors of the dental disc and bracket. Then try to round the needle cylinder and needle cylinder. If the roundness is still greater than 0.05mm, record the roundness value of each point of the needle cylinder and needle cylinder in detail. By analyzing these data, if the difference between the roundness values of the two diagonal points of the needle cylinder and the needle disk is less than 0.02mm, and the overall roundness of the needle cylinder and the needle disk is greater than 0.05mm, it can be basically judged that the appearance of the needle cylinder is oval, which should belong to the defects of the needle cylinder and the needle disk. If the roundness values of the whole circle are very close, only a local point exceeds the standard, and loosens the fastening screw. There is no change in the roundness value, and it can also be concluded that the roundness of the needle disc and needle cylinder has deviation, which belongs to the defective needle cylinder. It should be noted that. When detecting such defects. The work of parts 1.1 and 1.2 should be done carefully, the sampling data should be accurate and detailed, the analysis should be organized and the logic should be meticulous. Only in this way can the conclusion be accurate and stand scrutiny.

The accuracy of sinker, cams, or middle tray of jacquard machine cannot meet the standard

This kind of tray part is generally the carrier of a triangular seat. Although the flatness and roundness requirements are not as high as those of needle disc and needle cylinder, they often adjust the height or left and right direction with the change of products in the production process, rather than mechanical parts such as needle disc and needle cylinder. After a one-time adjustment, if they are not replaced, they will not be adjusted again. Therefore, during the adjustment of this kind of tray, the installation and adjustment of its positioning block become very key. Let’s take sinker as an example to introduce the specific method.

2.1 flatness adjustment

When the flatness of the tray is out of tolerance, first loosen the screws and positioning blocks on the tray and bracket, suck the dial indicator seat on the needle cylinder, place the meter on the end face of the tray, turn the machine to a bracket, lock the fastening screws between the bracket and tray, and observe the change of the meter needle. If there is any change, it proves that there is a gap between the bracket and the tray, which needs to be padded with gaskets. When locking the screw, the change of the gauge needle is less than 0.01mm. It should be noted that the contact surface between the bracket and the tray is large and is not on the same turning radius as the direction of the meter,

When locking the screw, although there is a gap, the value change of the watch needle may not be smaller. It may also become larger. The change in the size of the watch needle directly reflects the position of the gap between the bracket and the tray. As shown in Figure 3a, the reading of the dial indicator on the locking screw will become larger. If it is in the case shown in Figure 3B, the reading of the dial indicator on the locking screw will become smaller. The position of the gap can be judged according to different reading changes, and the flatness of the bracket can be adjusted by using shims, or the gap can be padded directly with shims. After the brackets and trays are padded one by one, check the flatness value of each bracket. If it exceeds the standard, pad it with gaskets to make the flatness reach the standard range.

Note: due to different materials of some machines, improper aging treatment or processing, or wrong operation during assembly, the flatness of the pallets of some machines will be out of tolerance. Generally, when adjusting the flatness, only check and adjust the flatness at the bracket, while the parts between the brackets are not considered. When there is a small amount of out of tolerance, it generally does not affect the use. In case of serious out-of-tolerance, it is another matter and shall be sent to machining for repair.

2.2 roundness adjustment

After the flatness adjustment is completed, continue to suck the dial gauge base on the needle cylinder. The gauge head refers to the contact surface between the positioning block on the bracket and the tray because when the left and right positions of the tray are adjusted, the tray moves according to this end face. If the column of the machine affects the operation of the dial indicator, the lever dial indicator can be replaced for adjustment. First, loosen the positioning block from the tray, and turn the machine to adjust the roundness to the standard range. The following matters shall be noted during adjustment:

a. When the roundness of the pallet is out of tolerance, it is only necessary to adjust the position of the diagonal positioning block so that the reading difference of the meter is less than 0.03mm. Because the adjustment range of the pallet is limited, it can ensure that the deviation of the diagonal positioning block in the running radius is controlled within 0.03mm. When the tray rotates in a small range, the positioning block can basically control the center position of the tray unchanged.

b. When adjusting the roundness, never use the positioning block to forcibly push the tray to the required position. In this way, although the reading of the meter is in the correct position, the tray will produce elastic deformation, which will not only affect the flatness of the tray but also change the roundness when adjusting the left and right positions of the tray. The correct approach is that no matter what method is used to change the tray position, the external force shall be removed, and then the reading of the meter shall be read. After adjusting to the required range, the locking principle of the positioning block is the same. It only sticks to the tray rather than against the tray to avoid elastic deformation of the tray, which is very important.

3. Adjustment of roundness and flatness of double jersey machine

When the roundness and flatness of the double-sided machine exceed the normal range, before adjustment, first make sure that the bearing and tooth disc in the Dating central sleeve has no looseness or the looseness is within the standard range. After confirmation, adjust according to steps.

3.1 flatness

Install the dial indicator as required and loosen all fastening screws of the tripod. Turn the dial indicator to a middle bearing foot, lock the fixing screws one by one, and observe the change of the dial indicator to determine whether there is a gap between the middle bearing foot and Dating and the specific position of the gap. The principle is similar to the reading change analysis method of the table when adjusting the flatness of the tray. Fill the gap with shims. After each screw position is adjusted, loosen the screw before adjusting the next screw until the reading change of the meter is less than 0.01mm when each screw is locked. After completing this work, turn the machine for a full circle to see if the levelness exceeds the normal range. If it exceeds the normal range, adjust it with shims.

3.2 circularity

After adjusting the flatness, install the dial indicator as required. Operate the machine and observe whether the roundness exceeds the normal range. If it exceeds the normal range, use the adjustment screw of the machine to adjust it to the range. Attention should be paid to the use of the adjusting screw. As the use of the tray positioning block, it can not be used to forcibly push the central sleeve into place, which will cause elastic deformation of the parts. The adjusting screw can be used to move the central sleeve to the required position, then loosen the adjusting screw, and then read the reading of the meter. After adjusting, the adjusting screw is also applied to the center sleeve, but the force can not be exerted on it. In short, the parts shall not generate internal stress after adjustment.

When adjusting the same roundness, you can also select six diagonal points as the benchmark, because although the tooth discs of some machines are not loose, their motion track is elliptical due to wear, and their circle center is not at a fixed point. As long as the difference of diagonal readings is within the range, it can be regarded as meeting the standard. However, when the movement track of the dental disc is elliptical due to the deformation of the disc, the deformation of the disc must be eliminated first to restore the movement track of the dental disc to a circle. Similarly, the phenomenon that flatness suddenly exceeds the normal range at a local point can also be judged as the result of tooth disc wear or deformation. If it is caused by large disc deformation, the large disc deformation should be eliminated; If it is caused by wear, it needs to be repaired or replaced according to the severity.

Related Product

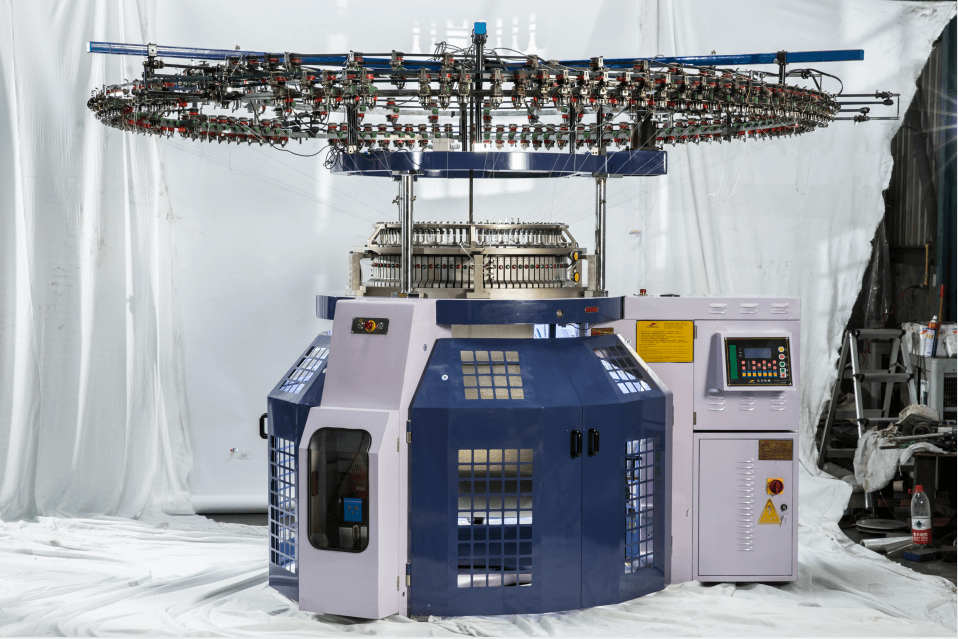

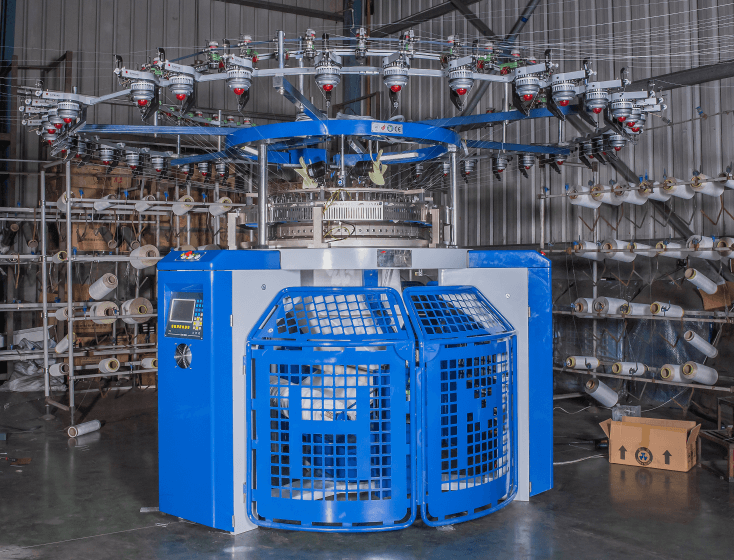

DOUBLE JERSEY Circular KNITTING MACHINE

DOUBLE JERSEY OPEN WIDTH KNITTING MACHINE

High speed three thread fleece circular knitting machine

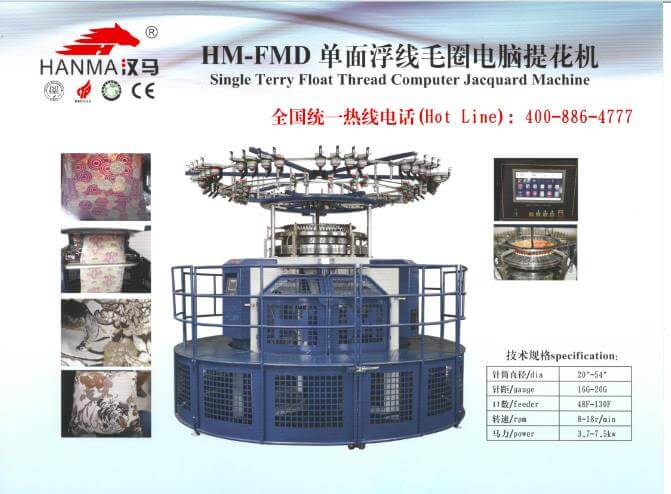

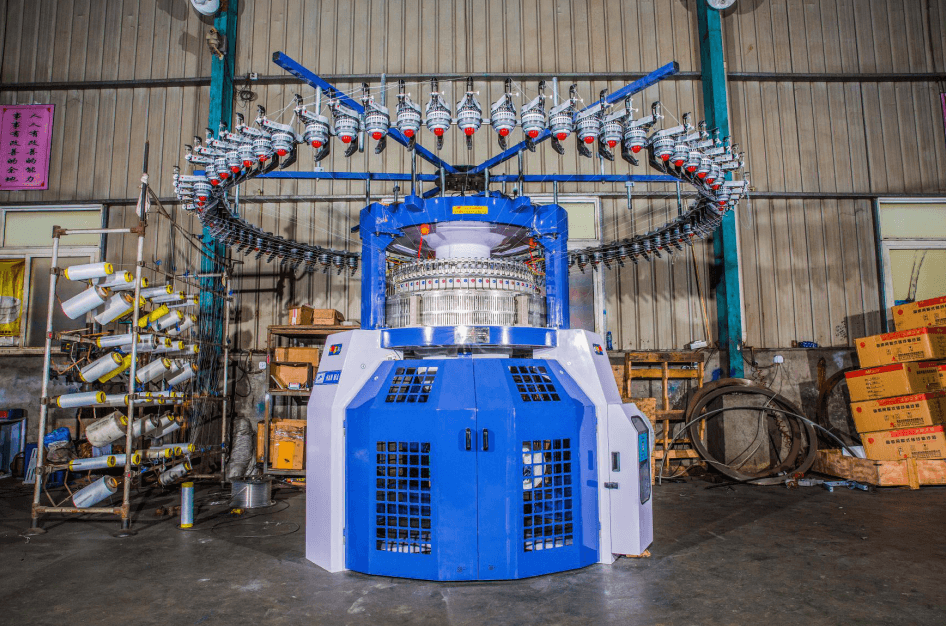

SINGLE TERRY JACQUARD CIRCULAR KNITTING MACHINE (THREE JACQUARD)

SINGLE TERRY FLOAT THREAD COMPUTER JACQUARD Circular knitting MACHINE

DOUBLE RIB JACQUARD CIRCULAR KNITTING MACHINE

Related Article

Rare earth heating fibers

Textile fabric width control

Several types of regenerated fibers that are easily confused.

Read moreSeveral types of regenerated fibers that are easily confused.

Key technologies for double-sided circular knitting machine needle plate calibration

Read moreKey technologies for double-sided circular knitting machine needle plate calibration

How a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)

Read moreHow a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)