That is, the fabric is formed by bending the yarn into circles and stringing each other with knitting needles. Knitted fabrics are divided into weft knitted fabrics and warp knitted fabrics.

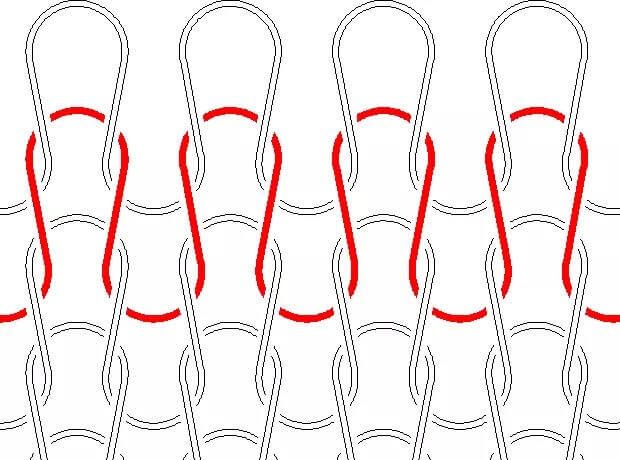

Weft knitted fabric is first woven horizontally. And it is formed by one continuous yarn beating into loops.

Weft knitted fabrics are easier to produce, but they are also easier to lose edges when cutting.

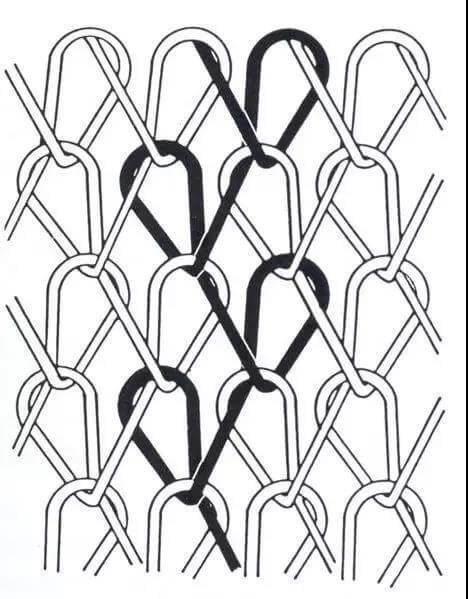

Warp knitted fabric is usually lengthwise, and its organization is zigzag so that it can make the coil form two or more continuous walls. Compared with weft knitted fabrics, it is usually smoother and more compact, resulting in less elasticity and preventing run resistance.

Characteristics of knitted fabrics

(1) Scalability. Knitted fabrics are made of yarns bent into circles and sleeved with each other. The coils have large flexibility up, down, left, and right. Therefore, they have good elasticity, fit with the body when wearing, are comfortable and convenient, and are suitable for stretching and bending during human movement.

(2) Softness. The raw material of knitted garment fabric is a fluffy and soft yarn with a small twist. There is a layer of tiny suede on the surface of the fabric. In addition, the tissue composed of coils is loose and porous, which reduces the friction between the skin and the surface of the fabric and gives people a comfortable and gentle feeling.

(3) Moisture absorption and air permeability. Because the coils constituting the knitted fabric are sleeved in series with each other, countless isolated airbags are formed inside the fabric, which has good heat preservation and air permeability. In addition, plant and animal fibers have a certain moisture absorption capacity, especially cotton fiber. Therefore, wearing cotton knitted clothes in summer feels cool without feeling stuffy and uncomfortable.

(4) Wrinkle resistance. When the knitted fabric is wrinkled by an external force, the coil can be transferred to adapt to the deformation under force; When the wrinkle force disappears, the transferred yarn can quickly recover and maintain its original state.

Common knitted fabrics

Sweat cloth

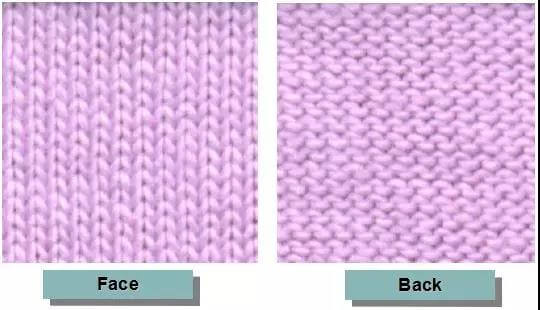

Sweat cloth is composed of continuous circular tissue. The front lines are clearer than the back lines and easy to identify. The cloth surface is smooth, the grain is clear, the texture is fine, and the hand feel is smooth. The longitudinal and transverse extensibility is better, and the transverse extensibility is greater than the longitudinal extensibility. Moisture absorption and air permeability are good, but they have detachability and crimping, and sometimes the coil skew phenomenon will occur.

Apply

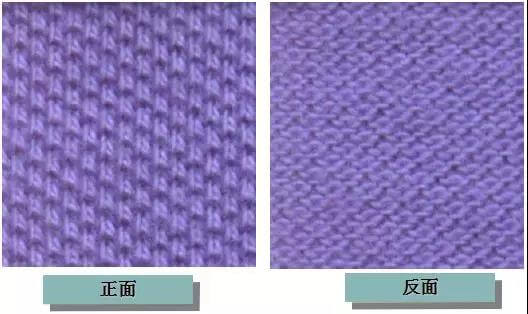

Bead mesh

Bead mesh fabric is composed of continuous knit stitch and tuck stitch, including 4-mold single bead, 6-mold bead, 8-mold bead, twill bead, sports bead, spandex bead, etc.

Apply

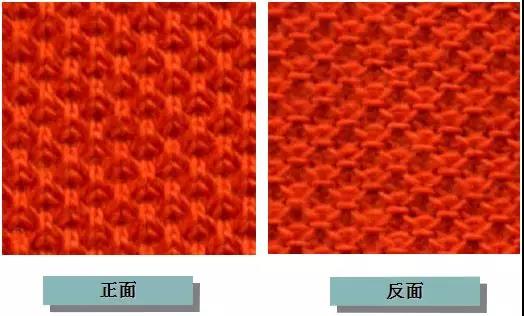

Fleece

Sweater cloth is a kind of knitted cloth, which is French Terry in English and called fleece after roughening. This kind of knitted fabric is mostly woven by displacement pad yarn, so it is called displacement cloth or sanitary cloth. Some places are called terry cloth and some places are called fish scale cloth. There are many varieties. (fish scale cloth is named because the back of the cloth is terry, and some look like fish scales.) the gram weight is generally between 190g / m2 and 350g / m2.

Rib Fabric

Rib knitted fabric is a kind of knitted fabric in which a yarn forms a coil on the front and backside in turn. Rib knitted fabric has the properties of separation, crimping, and extension of plain fabric, and also has great elasticity.

1×1 rib looks very similar to plain cloth, but the structure of the rib is loose, more elastic, and generally regardless of front and back.

The rib of other structures, such as 2×2 and 2×1 structures, is easy to be distinguished from other fabrics due to the particularity of their structure.

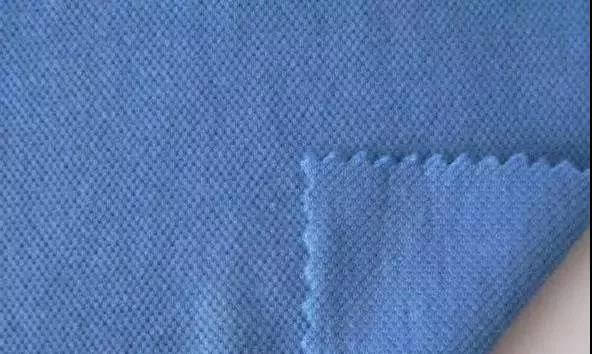

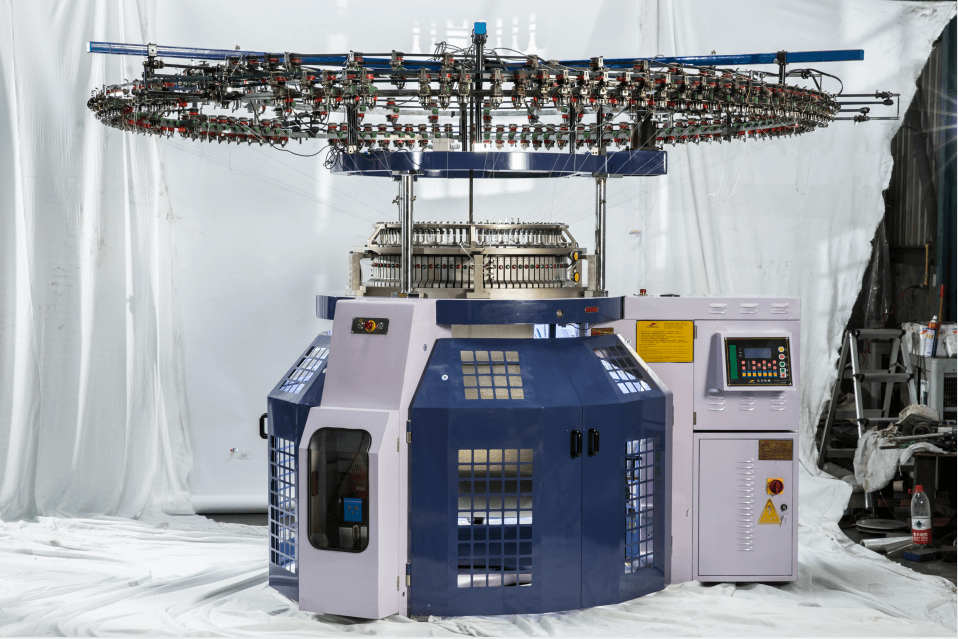

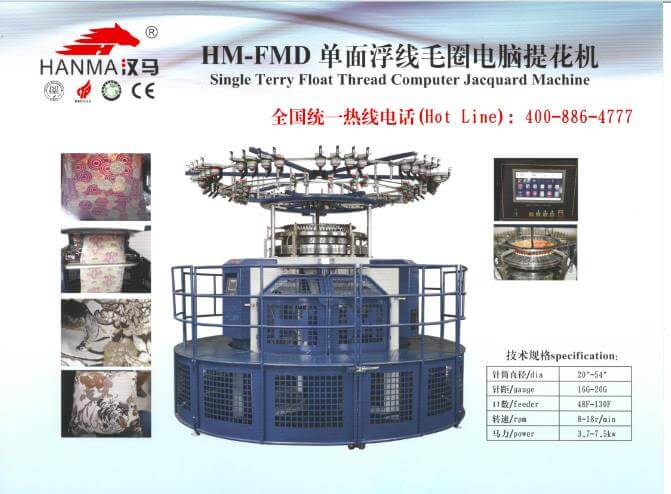

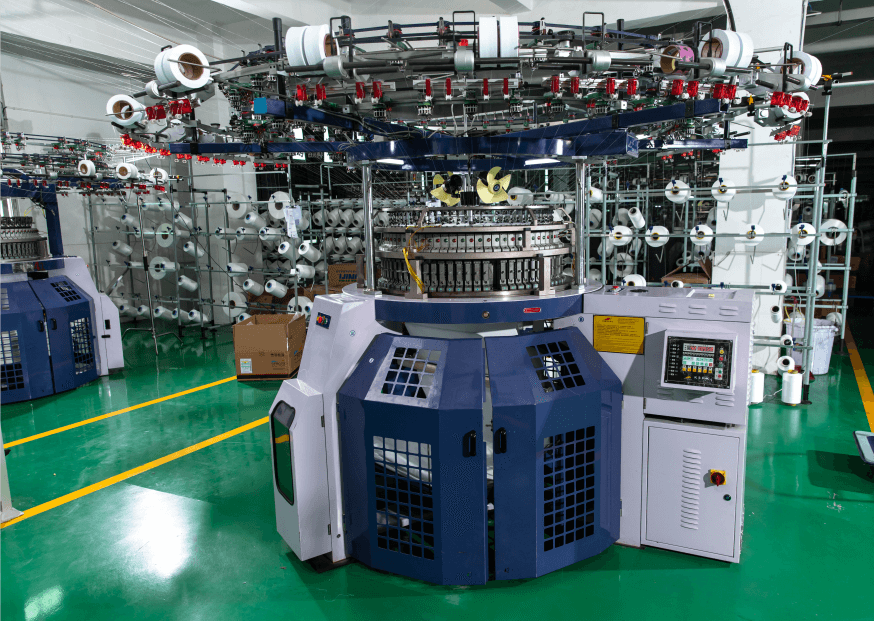

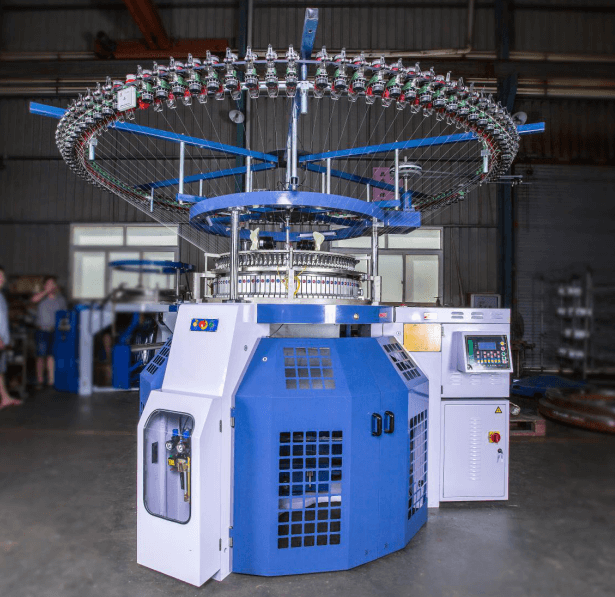

Roman Fabric

Roman cloth is a kind of knitted fabric, weft-knitted and made by a double-sided circular machine. Also known as Ponte de Roma, commonly known as chicken beating cloth. Roman cloth is a four-way cycle. The cloth surface is not as flat as ordinary double-sided cloth, with slightly irregular horizontal bars. The fabric has good horizontal and vertical elasticity, but its horizontal tensile performance is not as good as that of double-sided cloth, with strong moisture absorption. Used for making close-fitting clothes, breathable, soft, and comfortable.

Related Product

Related Article

Rare earth heating fibers

Textile fabric width control

Several types of regenerated fibers that are easily confused.

Read moreSeveral types of regenerated fibers that are easily confused.

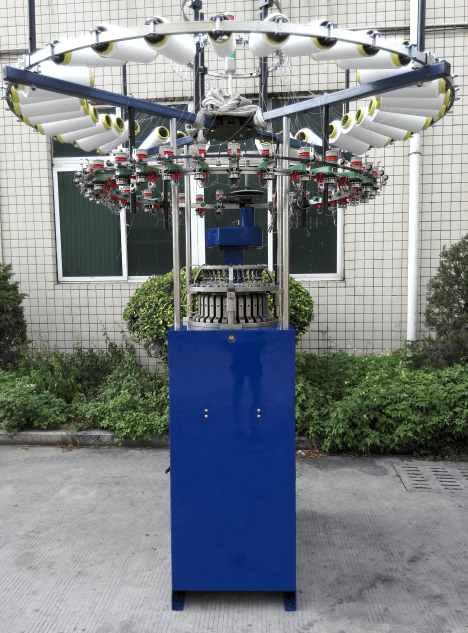

Key technologies for double-sided circular knitting machine needle plate calibration

Read moreKey technologies for double-sided circular knitting machine needle plate calibration

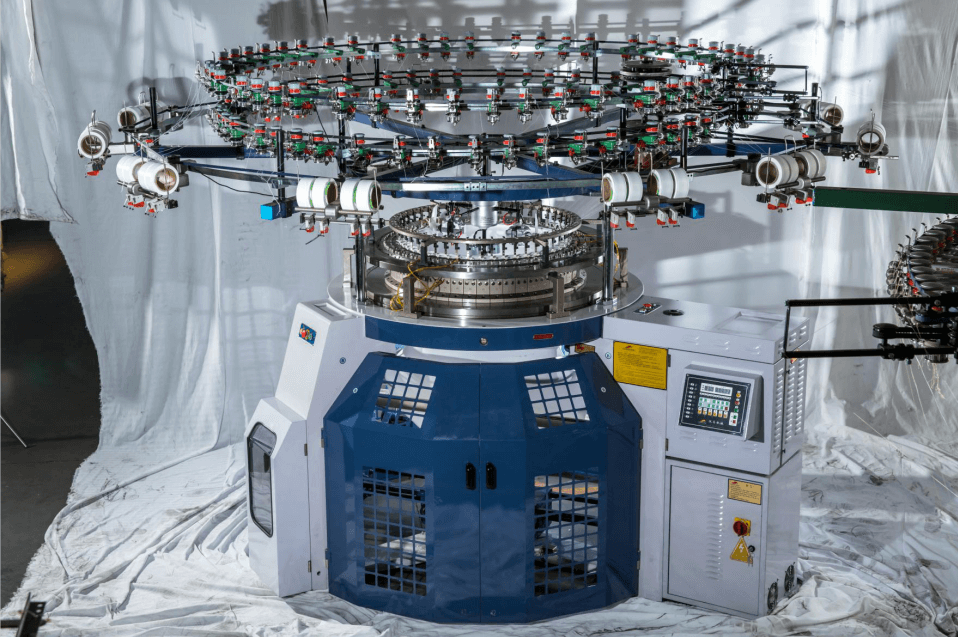

How a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)

Read moreHow a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)