When the polyester knitted fabric is dyed with dispersed dyes, why is the small sample inconsistent with the large sample?

Dyeing factories usually make small samples in the laboratory and then enlarge the samples in the workshop according to the small samples. The reasons for the inconsistent color light and the color difference between the small samples and the large samples may be in the following aspects.

1、 Different grey cloth

The grey cloth shall be refined or degreased before dyeing, and the small sample may not be pretreated, or the small sample treatment method is different from the large sample production in the workshop. The moisture content of grey cloth is different, and the moisture content of small samples has a great impact. Due to different moisture content, the weighing is also different. Therefore, it is required that the grey cloth for the small sample must be completely consistent with the grey cloth produced in the workshop.

In addition, is the pre-treatment of grey cloth predetermined? If the large sample grey cloth has been shaped, the small sample grey cloth has not been shaped, and even the large sample and small sample have been shaped, and the different setting temperatures can also cause different color absorption.

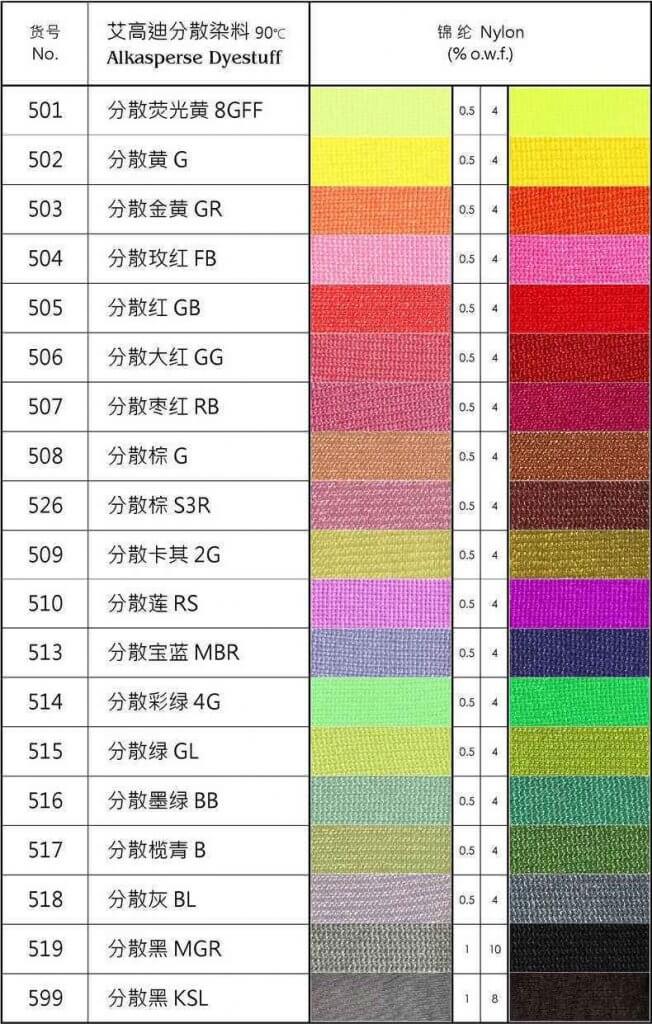

2、 Different dyes

Although the dyes used for small samples are the same as those used for large samples in terms of variety and strength, the differences between small samples and large samples may be caused by different batch numbers or inaccurate weighing of small samples. It is also possible that the dyes for large-scale production have been caked and damped, and some dyes are unstable, resulting in a decrease in strength.

3、 Different pH value of dyeing bath

Generally, the pH value of the dyeing bath is more accurate for small samples, while the pH value is unstable or no acid-base buffer is added during large sample production. Due to the alkalinity of steam during dyeing, the pH value increases in the middle of large sample production, and some disperse dyes such as ester group, amido group, and cyano group are hydrolyzed under high temperature and alkaline conditions. The carboxyl group of some dyes can be ionized under alkaline conditions, the water solubility increases, and the dye uptake decreases. When the pH value of most disperse dyes is 5.5 ~ 6, the color light is normal and stable, and the dye uptake is also high.

However, the color light changes when the pH value increases. For example, disperse black s2bl, disperse dark blue HGL, disperse grey m, and other dyes change significantly when pH > 7. Sometimes grey cloth is alkaline without sufficient cleaning after pretreatment, and the pH value of the dyeing bath increases during dyeing, which affects the color light.

4、 Effect of bath ratio

In the small sample test, the bath ratio is generally large [1: (25 ~ 40)], while the large sample bath ratio varies according to different equipment, which is generally 1: (8 ~ 15). Some disperse dyes have small bath ratio dependence and some have large dependence, so the color difference is caused by the different bath ratio between the small sample and the large sample.

5、 Impact of post-treatment

Post-treatment is one of the reasons affecting the color difference. Especially for medium and dark colors, if reduction cleaning is not carried out or cleaning is not clean, in addition to floating color, it can also affect the color light and produce a certain color difference. Therefore, the reduction cleaning must be consistent with the small sample and the large sample.

6、 Effect of heat setting

Disperse dyes can be divided into high-temperature type, medium temperature type, and low-temperature type.

The same type of dye shall be selected during color matching. In case of high-temperature and low-temperature color matching, the setting temperature shall not be too high during thermal setting, so as to avoid high temperature, which will cause the sublimation of some dyes, affect the color light and produce a color difference. The setting conditions of small samples and large samples are basically the same.

Because the pre-treatment setting or not and the setting conditions (temperature) have a great impact on the color absorption of polyester (the greater the setting degree, the lower the dye uptake), the cloth for small samples must be consistent with the large samples (i.e. duplicate samples of semi-finished products in the workshop before production), which is one of the keys.

Related Article

Rare earth heating fibers

Textile fabric width control

Several types of regenerated fibers that are easily confused.

Read moreSeveral types of regenerated fibers that are easily confused.

Key technologies for double-sided circular knitting machine needle plate calibration

Read moreKey technologies for double-sided circular knitting machine needle plate calibration

How a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)

Read moreHow a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)