Introduction of circular knitting machine

Until now, circular knitting machines have been designed and manufactured for the mass production of knitted fabrics. The special properties of knitted fabrics, especially fine fabrics made by the circular knitting process, makes these types of fabric suitable for application in clothing, industrial textiles, medical and orthopaedic garments, automotive textiles, hosiery, agro and geotextiles, etc. The most important areas for discussion in circular knitting technology are increasing production efficiency and improving fabric quality as well as new trends in quality clothing, medical applications, electronic garments, fine fabrics, etc. Famous manufacturing companies have pursued developments in circular knitting machines in order to extend into new markets. Textile specialists in the knitting industry should be aware that tubular and seamless fabrics are highly suitable for various applications not only in textiles but also in medical, electronic, agriculture, civil and other fields.

Characteristics of knitted structures

Knitted structures are composed of interlocking yarn loops with an anisotropic structure. The properties of knitted fabrics differ from those of woven structures because the yarns are not orientated in any direction, and the yarn direction changes continuously. Yarn loops can move across each other in the structure, and knitted fabrics are elastic and easy to shape. Lines of tying knots of weft-and-warp-knitted fabrics are perpendicular to each other. Warp-knitted yarns meander more from the knitting direction than weft-knitted yarns do, resulting in lower yarn mobility and thus increased stability in warp-knitted structures.

High yielding prior to tearing is a characteristic of knitted structures because the yarns in the structure can slide due to strain forces. Knitted structures also have high bursting strength, and they usually have lower yarn densities than woven structures. This leads to higher porosity as well as to lower thickness and compression strength. Generally, knits are highly conformable, and they are able to form smooth and even contact over nonuniform anatomical structures. In addition, knitted structures function as cavity-filling bulk because they can be compressed and inserted easily into small cavities (Heniford, 2011).

Both flat and tubular structures are possible using knitted fabrics. The fabrication of holes in a knitted structure is also possible, which increases the permeability of the knitted fabric. High surface area and open pore structure yield high in growth potential, and the properties of knitted spacer structures are determined by the characteristics of surface knits and yarn properties in the interspace. Surface knits increase the elasticity and permeability of the structure (Epstein et al., 1992; Miravete, 1999; Horrocks and Anand, 2000; Hutmacher, 2000; Heniford, 2011).

Weft knitting, weft-knitted fabric and knitwear design

Knitting machines can be grouped in many ways. One way is by the gauge—the number of needles per inch or centimetre. The exception to this is for fully-fashioned machines, where the gauge is often expressed as the number of needles per one and a half inches. A heavy-gauge fabric is one that has been knitted on a machine with a few needles per inch (2½ to 5 needles per inch are common gauges in the UK). A fine-gauge fabric is one that has been knitted in fine yarn on an 18- to 32-gauge machine (UK).

‘Knitwear’ (knitted garments usually with integral ribs) is normally produced on 2½ – to 14-gauge machines, with traditional type knitwear (lambswool, botany and cashmere) more likely to be in the 7- to 12-gauge range. Jersey (continuous fabric) is produced on finer gauge machines, from 18–32 gauge.

General terms and principles of knitting technology

Knitted structures are progressively built up from row after row of intermeshed loops. The newly-fed yarn is converted into a new loop in each needle hook. The needle then draws the new loop headfirst through the old (fabric) loop, which it has retained from the previous knitting cycle. The needles, at the same time, release, (cast–off or knock–over) the old loops so that they hang suspended by their heads from the feet of the new loops whose heads are still held in the hooks of the needles.

A cohesive knitted loop structure is thus produced by a combination of the inter- meshed needle loops and yarn that passes from needle loop to needle loop.

Introduction to 3D knitted structures

Three-dimensional knitted fabrics have been widely used in many fields, especially in technical textiles. The development of 3D knitted fabrics is based on 2D knitted fabrics. However, while a considerable amount of research has been performed on 2D knitted fabrics, by comparison little is known about the mechanical properties and applications of 3D knitted fabrics. This chapter provides a description of the three types of 3D knitted fabrics currently available, which are broadly categorized as multiaxial warp-knitted fabrics, space fabrics (or sandwich fabrics), and 3D knitted fabrics (or near-net-shaped knitted fabrics). The structures, properties, production, and applications of these different 3D knitted fabrics are described separately.

Fabric machines and garment-length machines

Weft knitting machines may be broadly grouped according to the end product as either:•

circular machines, knitting tubular fabric in a continuous uninterrupted length of constant width, or•

flat and circular machines, knitting garment–length sequences, which have a timing or counting device to initiate an additional garment-length programming (‘machine control’) mechanism. This coordinates the knitting action to produce a garment-length structural repeat sequence in a wale-wise direction. The garment width may or may not vary within the garment length.

The difference between fabric and garment-length knitting is best understood in terms of hand flat knitting. If the knitter merely traverses the cam carriage backwards and forwards across the needle bed, a continuous fabric length will be knitted. However, if the knitter counts the traverses and alters the cam box settings at predetermined traverses, a garment-length sequence can be knitted.

Underwear may be knitted either in garment-length or fabric form, whereas knitwear is normally in garment-length form, usually knitted in machine gauges coarser than E 14. Jersey wear is cut and made up from fabric usually knitted on large circular machines (26-inch or 30-inch diameter), although there are larger and smaller diameter machines used. Generally, gauges are finer than E 14.

Fabric machines

Large diameter, circular, latch needle machines (also known as yard goods or piece goods, machines) knit fabric, at high speed, that is manually cut away from the machine (usually in roll form) after a convenient length has been knitted. Most fabric is knitted on circular machines, either single-cylinder (single jersey) or cylinder and dial (double jersey), of the revolving needle cylinder type, because of their high speed and productive efficiency.

Circular machines employing bearded needles are now obsolete. Although sinkerwheel and loop heel frames could knit high-quality speciality fabrics, their production rates were uncompetitive.

Unless used in tubular body-width, the fabric tube requires splitting into open-width. It is finished on continuous finishing equipment and is cut-and-sewn into garments, or it is used for household and technical fabrics. The productivity, versatility and patterning facilities of fabric machines vary considerably. Generally, cam settings and needle set-outs are not altered during the knitting of the fabric (see also Chapter 13, The production of weft knitted fabric).

Garment-length machines

Garment-length machines include straight bar frames, most flats, hosiery, legwear and glove machines, and circular garment machines including sweater strip machines, producing knitwear, outerwear and underwear. On these machines, the garment sequence control with the timing/counting device, collectively termed ‘the machine control’, automatically initiates any alteration to the other facilities on the machine needed to knit a garment-length construction sequence instead of a continuous fabric.

This machine control may have to initiate correctly-timed changes in some or all of the following: cam-settings, needle set-outs, feeders and machine speeds. It must be able to override and cancel the effect of the patterning mechanism in rib borders and be easily adjustable for different garment sizes.

Also, the fabric takedown mechanism must be more sophisticated than continuous fabric knitting. It has to adapt to varying rates of production during the knitting of the sequence and, on some machines, be able to assist both in the setting-up on empty needles and the take away of separate garments or pieces on completion of the sequence.

Garments may be knitted to size either in tubular or open-width; in the latter case, more than one garment panel may be knitted simultaneously across the knitting bed. Large-diameter circular machines and wide V-bed flat machines can knit garment blanks that are later split into two or more garment widths (blanket–width knitting) (see also Chapter 20, Circular garment–length machines).

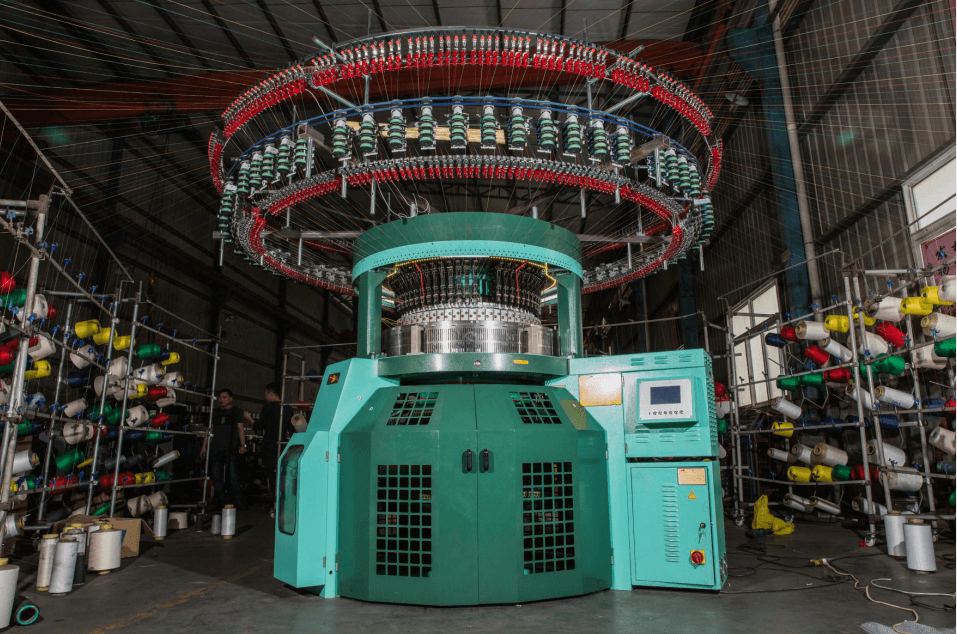

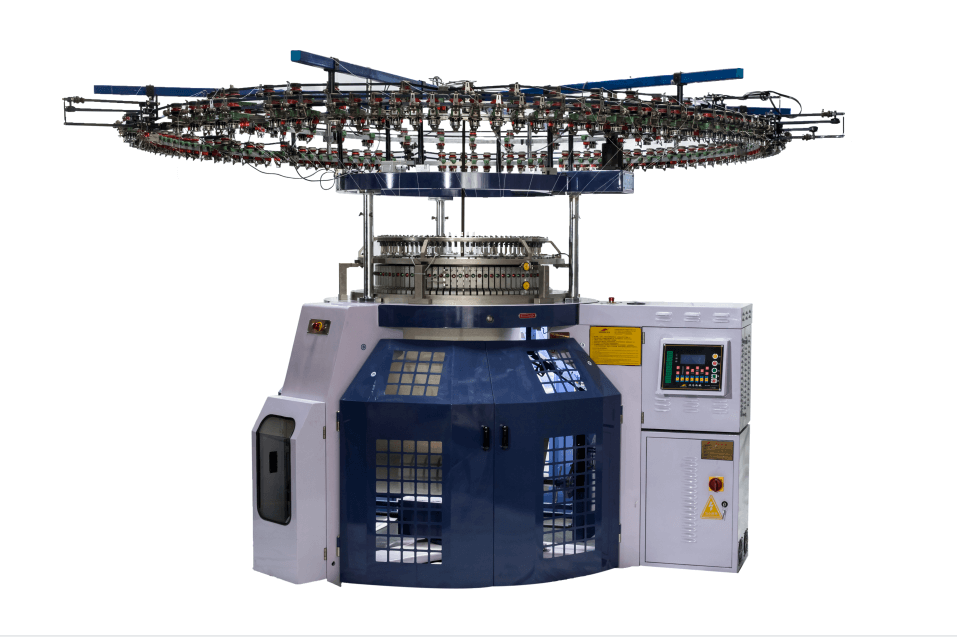

Parts of Circular Knitting Machines

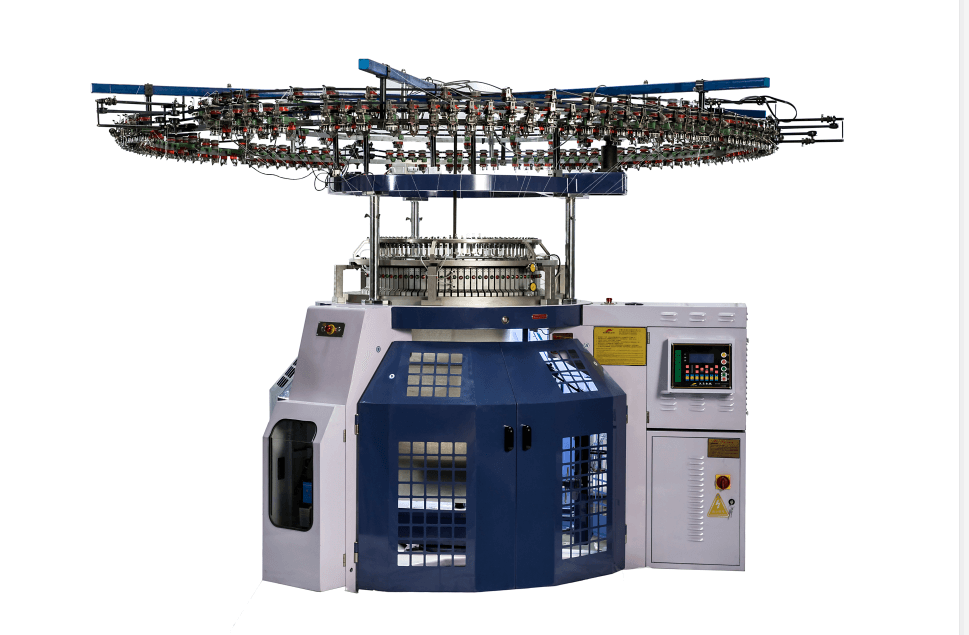

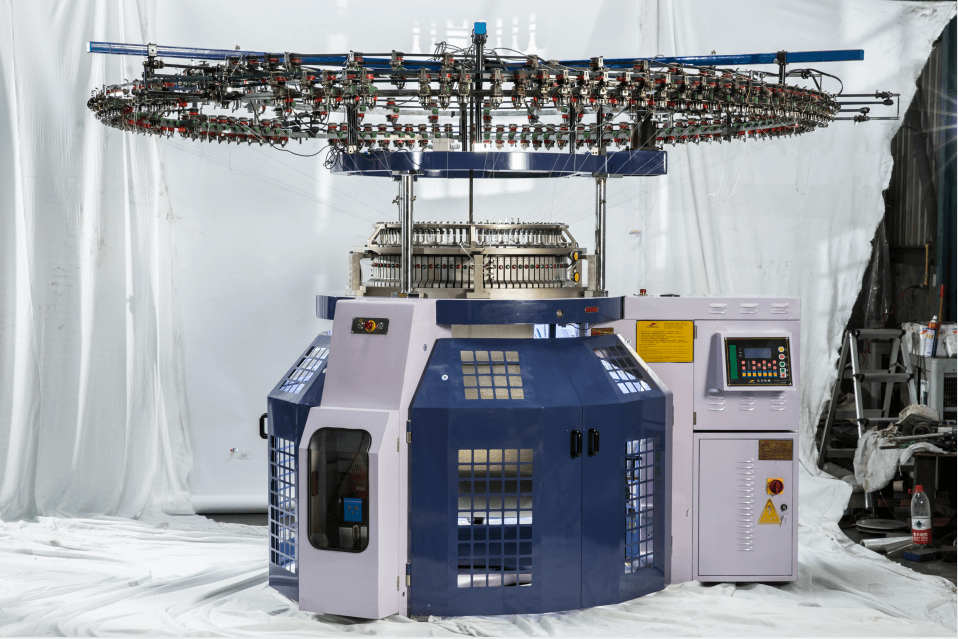

The circular knitting machine is composed of a frame, a yarn supply mechanism, a transmission mechanism, a lubricating and dust removal (clean) mechanism, an electric control mechanism, a pulling and winding mechanism, and other auxiliary devices.

Rack part

The frame of the circular knitting machine is composed of three legs (commonly known as the lower leg) and around the (also square) tables. The lower leg is fixed by a three-prong, and the table (commonly known as the large plate) has three uprights (commonly known as the upper leg or straight leg). ), a creel seat is installed on the straight leg. A safety door (also called a protective door) is installed in the gap between the three lower legs. The rack must be stable and safe. It has the following characteristics:

- The lower foot adopts a built-in structure

All electrical wiring and tools of the motor can be placed in the lower leg, making the machine safe, simple and generous. - The safety door has a reliable function

When the door is opened, the machine will automatically stop running, and a warning will be displayed on the operation panel to avoid accidents.

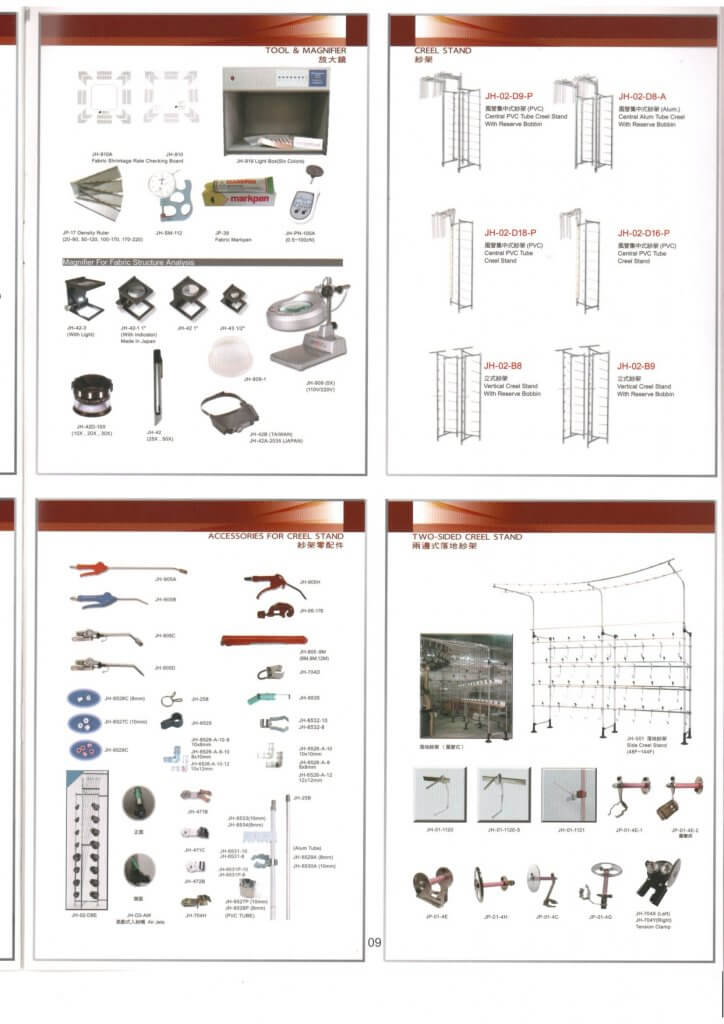

Yarn supply mechanism

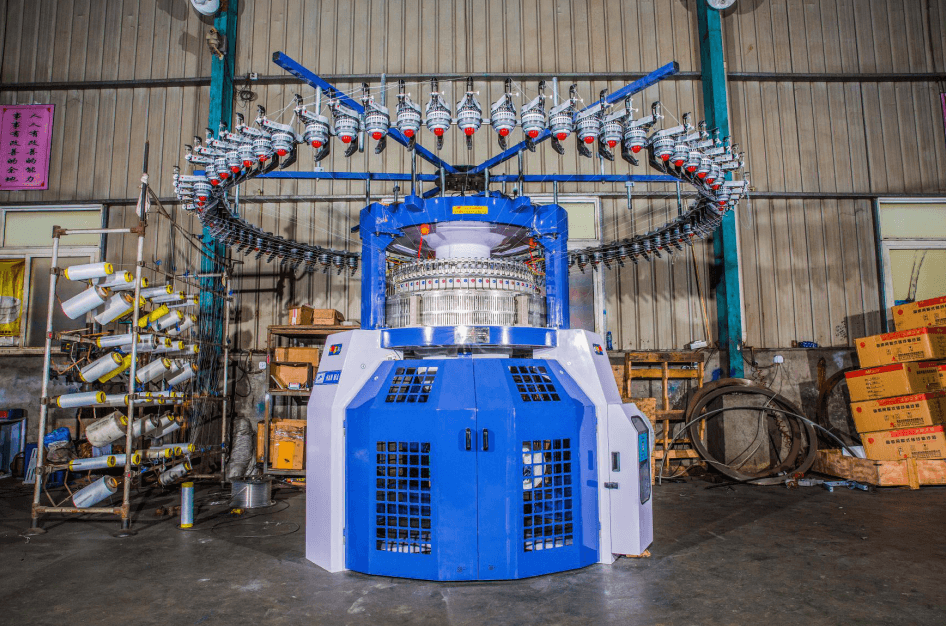

The yarn feeding mechanism is also called the yarn feeding mechanism, including the yarn rack, the yarn storage device, the yarn feeding nozzle, the yarn feeding tray, the yarn ring bracket and other components. - Creel

The creel is used to place the yarn. It has two types: umbrella type creel (also called top type creel) and floor type creel. Umbrella creel occupies a small space, but can not connect spare yarn, suitable for small local enterprises. The floor-standing creel has a triangular creel and a wall creel (also called a two-piece creel). The tripod creel is more convenient to move, making it more convenient for the operator to wear the yarn; the wall creel is arranged neatly and beautifully, but it occupies a relatively large area and it is convenient to place spare yarns. It is suitable for enterprises with large factories.

- Yarn feeder

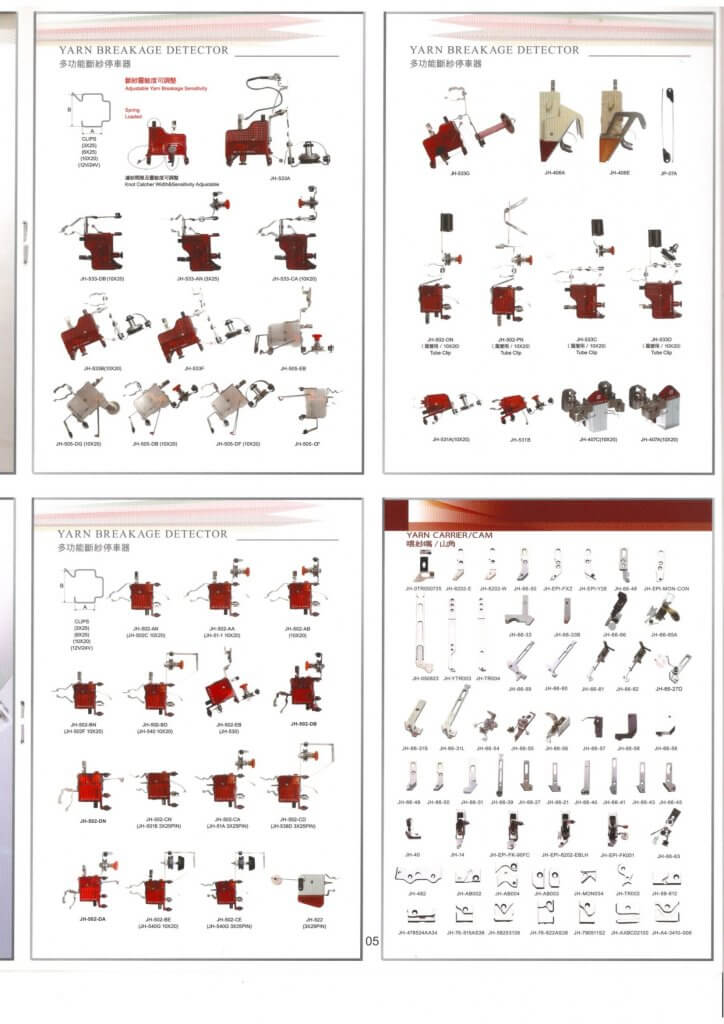

The yarn feeder is used for winding yarn in three forms: ordinary yarn feeder, elastic yarn feeder (used when spandex bare yarn is interwoven with other fiber yarns), and yarn storage device for electronic gap (used by jacquard circular knitting machine). Due to the different types of fabrics produced by knitting circular knitting machines, the yarn feeding methods used are also different. Generally, there are positive yarn feeding (yarn is wound on the yarn storage device for 10-20 laps), semi-negative yarn feeding (yarn is in the There are three types of yarn winding (1~2 laps on the storage device) and passive yarn feeding (yarn is not wound on the storage device).

- Yarn feeder

Yarn feeder is also called steel shuttle or yarn guide. It is used to feed the yarn directly to the knitting needles. It has many types and shapes, including single-hole yarn feeder, two-hole one-slot yarn feeder, etc. - Other

The sand tray is used to control the amount of yarn fed in the knitting production of the circular knitting machine; the yarn bracket can hold the large ring where the yarn storage device is installed. - Basic requirements for yarn supply mechanism

(1) The yarn feeding mechanism must ensure the uniformity and continuity of the yarn feed and tension, and ensure that the size and shape of the loops in the fabric are consistent, so as to obtain a smooth and beautiful knitted product.

(2) The yarn supply mechanism must ensure that the yarn feed tension (yarn tension) is reasonable, so as to reduce the occurrence of defects such as missing stitches on the cloth surface, reduce weaving defects, and ensure the quality of the knitted fabric.

(3) The yarn supply ratio between each knitting system (commonly known as the number of lines) meets the requirements. It is convenient to adjust the yarn supply amount (referring to the yarn feeding tray) to meet the demand for yarn feeding of different colors and varieties.

(4) The yarn hook must be smooth and free of burrs, so that the yarn is placed neatly, and the tension is even, which can effectively prevent yarn breakage [1].

Weaving mechanism

The knitting mechanism is the heart of the circular knitting machine, which is mainly composed of needle cylinder, knitting needle, cam and cam seat (triangular seat is also called saddle., sinker (only available on single jersey) and other components. - Syringe

Most of the needle cylinders used in the circular knitting machine are of the insert type, which is used to place the knitting needles. - Triangle

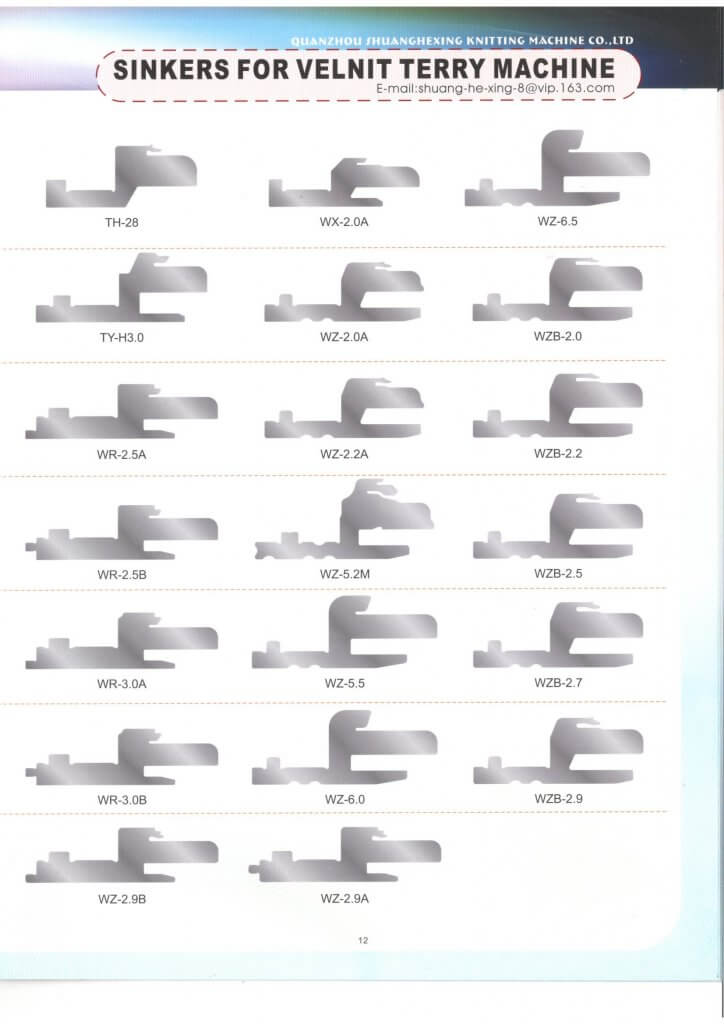

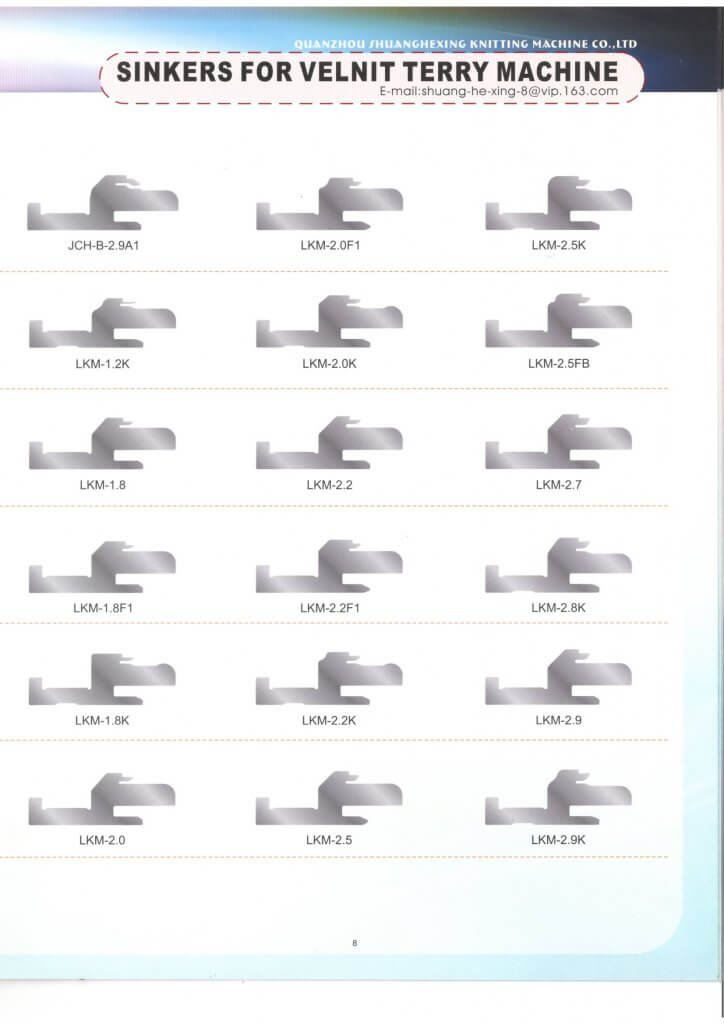

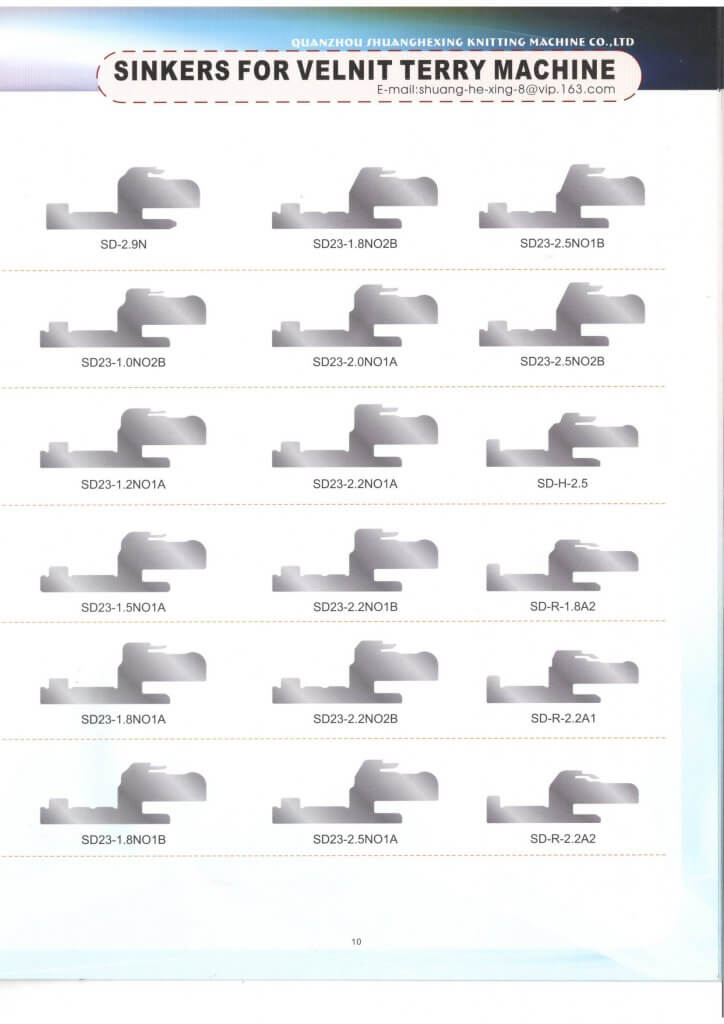

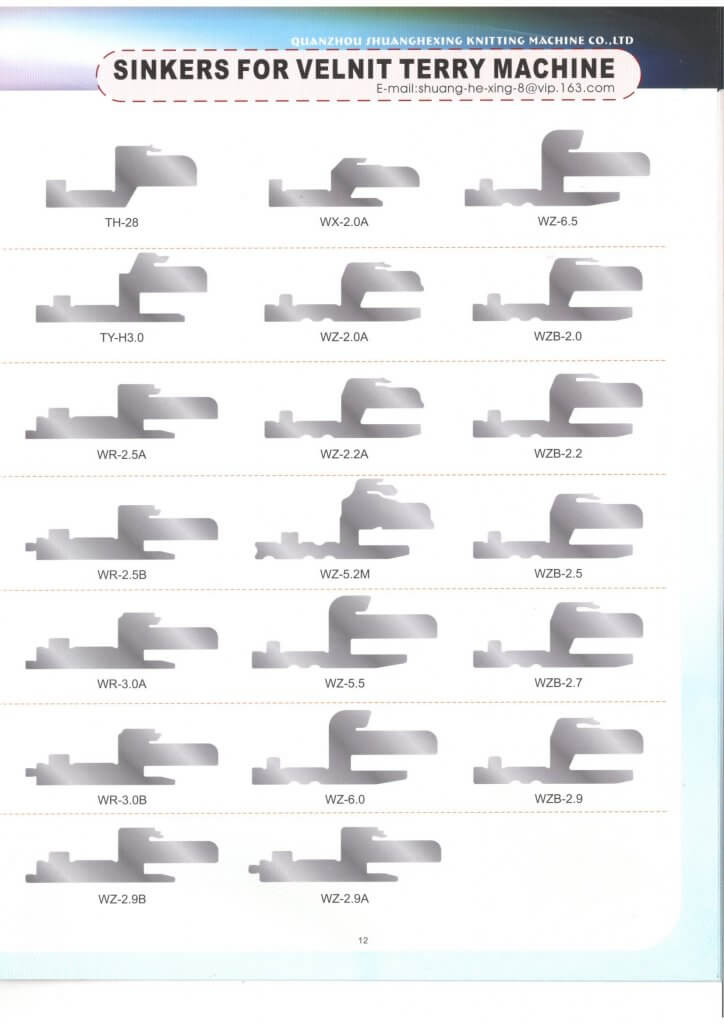

Triangle is also called mountain corner and water chestnut. It controls the reciprocating movement of the knitting needles and sinkers in the needle cylinder groove according to the different needs of the knitting varieties of the circular knitting machine. There are five types of triangles: loop triangle (full-needle triangle), tuck triangle (half-needle triangle), float triangle (flat-needle triangle), anti-string triangle (fat flower triangle), and pin triangle (proofing triangle). - Sinker

Sinker, also known as Sinker, is a unique knitting machine part of single jersey machine, used to cooperate with the normal production of knitting needles.

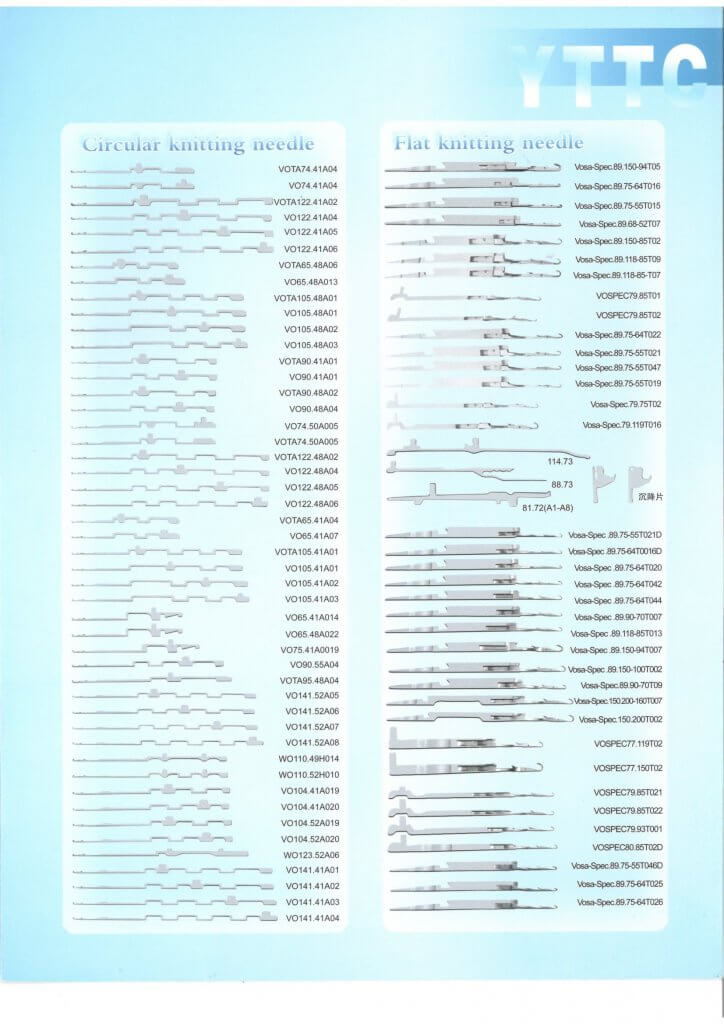

- Knitting needles

Knitting needles are distinguished by the height of the same type of needle, and its function is to complete the work from yarn to fabric.

- Triangle seat

The triangle seat is also called a saddle and is used to place the triangle. - Requirements for knitting machine parts

(1) The needle track (commonly known as the runway, which is the groove on the triangle) must be smooth and free of burrs, and the connection between the triangle block and the block needs to be well matched.

(2) The knob on the cam seat to adjust the depth of the crimping needle (bending depth) must be flexible and effective.

(3) Ensure that the height of the needle and the depth of the needle in the needle path of the knitting needle can meet the technological requirements.

Pull and take-up mechanism

The function of the pulling and winding mechanism is to pull the knitted fabric knitted by the circular knitting machine from the knitting area, and wind (or fold) it into a certain package form. The pulling and rewinding mechanism includes the spreading frame (cloth support frame), transmission arm (wall panel), adjusting gearbox, and other parts. Its characteristics are as follows:

- There is an induction switch under the big plate. When a transmission arm equipped with cylindrical nails passes through, a signal will be sent out to determine the data of the roll and the number of revolutions of the circular knitting machine, so as to ensure the weight of the cloth (dropping). Uniformity.

- The winding speed is controlled by a gear box, with 120 or 176 stages, which can accurately meet the needs of various patterns and colors of the winding tension in a wide range.

- On the operation panel, you can set the number of revolutions required for each piece of cloth weight. When the number of revolutions of the large circular knitting machine reaches the set value, it will automatically stop, so as to control the weight deviation of each piece of knitted fabric within 0.5 kg.

Transmission mechanism

The transmission mechanism is a stepless variable speed motor controlled by a leveler. The motor uses a V-belt or a timing belt (toothed belt) to drive the driving shaft gear, and at the same time transmits it to the large plate gear, so as to drive the needle cylinder to run with the knitting needles for knitting. The driving shaft extends to the large circular knitting machine, and drives the yarn feeding tray to convey the yarn according to the amount. The transmission mechanism is required to run smoothly without noise.

Lubrication and dust removal mechanism

The knitting circular knitting machine is a set of high-speed and coordinated precision system. Because the yarn will produce a lot of fly and dust during the knitting process, the central part of the finished knitting is easy to be unsmooth due to fly, dust and oil stains. It will damage the large circle machine, so the lubrication and dust removal (cleaning) of the running parts are very important. The lubrication and dust removal season of the circular knitting machine has the following functions and characteristics: - The special oil mist sprayer provides good lubrication for the surface of woven parts, and the oil level indication and oil consumption are visible. When the amount of fuel injection engine oil is insufficient, Great Circle will automatically stop running and give a warning on the operation panel.

- The new type of electronics is an automatic fuel dispenser, which makes the setting and operation more convenient and intuitive.

- The radar fan has a wide range of dust removal, which can remove impurities such as flying flowers from the creel, yarn storage device and knitting parts in a wide range, and avoiding poor yarn supply due to entanglement of impurities such as flying flowers.

Electrical control system

The electrical control system is used to complete the setting of operating parameters, simple button operation, and fault automatic stop instructions. - The control panel is composed of a microcomputer and a highly integrated control circuit, with convenient parameter setting, reliable button operation, and intuitive information display.

- The frequency converter is an important part of the AC control system of the motor (motor), which can achieve the purpose of changing the motor speed by controlling the output frequency. The speed can be adjusted in a wide range, and the start, stop, and slow performance can be set by parameters, which can be fast, stable and avoid impact.

- The wiring in the electrical control box is clear and orderly, and the entire box is inside the lower leg, which can effectively ventilate and prevent dust. The electrical wiring is in a hidden place, giving consideration to beauty and safety.

Accessory device

When the knitting needle breaks, the prober will transmit the signal to the control system, and the circular knitting machine will stop in about 0.5 seconds. There is also a cloth probe. After the slipping phenomenon occurs on the large circle machine, the machine will automatically stop, etc.

Types of Circular Knitting Machines

Knitting circular knitting machines are generally divided into two categories: single-sided series and double-sided series. But according to the types of fabrics processed and produced (academically called fabrics. Commonly called grey fabrics in factories), there are the following types:

Single side series

The single jersey series circular knitting machine is a machine with a needle cylinder. It is divided into the following categories.

- Single jersey circular knitting machine

Ordinary single jersey knitting machines have many loops (usually 3~4 times the diameter of the needle cylinder, that is, 3 routes∕25.4mm~4 routes∕25.4mm). For example, a 30″ single jersey machine has 90F~120F, The 34″ single-sided machine has 102~126F circuits, etc., with high speed and high output. In our country, some knitting enterprises are called multi-triangular knitting machines (mainly arising from the Z241 type).

Ordinary single jersey circular knitting machines have single needle track (one track), two needle tracks (two tracks), three needle tracks (three tracks), four needle tracks and six needle tracks. Most of them are currently used in knitting enterprises. The four-needle single-sided circular knitting machine is used. It uses the organic arrangement and combination of knitting needles and triangles to weave various new fabrics.

- Single terry circular knitting machine

Single-sided terry machine is also called single-sided towel machine. It has a single needle track, double needle track and four needle track models, and has a positive wrapping terry machine (the terry yarn wraps the ground weave yarn inside, that is, the terry yarn is displayed on the front of the fabric. The yarn of the organization is covered in it) and the turn-up terry machine (that is, the terry fabric that we usually see, the yarn of the ground weave is on the opposite side of the fabric), which uses the arrangement and combination of sinkers and yarns. To weave and produce new fabrics.

- Three thread circular knitting machine

The three-thread inserting machine is called a sweater or flannel machine in knitting enterprises. It has single-needle, double-needle and four-needle models, which are used to produce all kinds of fleece and non-pull fleece products. He uses knitting needles and arranging yarns to produce new fabrics.

- Jacquard single jersey circular knitting machine

Jacquard single jersey circular knitting machine has two types: small jacquard machine and large jacquard machine.

1) Small single jacquard knitting circular knitting machine

Small jacquard knitting circular knitting machines are called mechanical jacquard knitting machines in knitting enterprises. It is simple, convenient and quick to change varieties, but it has low speed and low output. It has several types of jacquard wheel type (commonly known as flower plate type), pick type (swing type), drum type, and insert type. It is used to weave and produce various single-sided small jacquard fabrics, with ordinary single-sided and ordinary loops. , Sweaters, transfer loops and other small jacquard machines.

2) Large single jacquard circular knitting machine

Large single jacquard knitting circular knitting machine is commonly known as computer jacquard circular knitting machine, because it inserts the designed floppy disk into the computer, and then enters the program to perform knitting production, so it is also called the fool circular knitting machine. The machine adopts a computer program to select knitting needles for knitting, non-knitting and tucking. There are two power positions (loop formation and floating yarn, loop formation and tuck) and three power positions (one way can simultaneously knit, tuck and float ), it is used to weave and produce knitted fabrics with large patterns, and can change the color of the yarn. There are four colors, five colors, six colors and eight colors that can be changed mutually, with large jacquard single-sided, jacquard wool Jacquard machines for loops, jacquard sweaters, transfer loops, etc.

The computer jacquard knitting circular knitting machine greatly shortens the product design cycle, reduces the cost of the circular knitting machine, and greatly improves the product quality, which improves the economic and social benefits of the enterprise, and at the same time improves the competitiveness and resilience of the enterprise.

Double circular knitting machine

The double-sided knitting circular knitting machine is a circular knitting machine with two needle cylinders, namely an upper needle cylinder (commonly known as a needle plate) and a lower needle cylinder, and are arranged perpendicular to each other, that is, the needle plate and the needle cylinder are arranged vertically at 90 degrees. It mainly has the following types.

- Rib knitting machine

Rib knitting machine is a special model of double-sided circular knitting machine. It has (1+1) needle track (one needle track on the dial, one needle track on the needle cylinder), (2+2) needle track, (2+4) needle track and (4+4) needle track. Use the mutual arrangement and combination of triangles and knitting needles and yarn arrangement to weave and produce new knitted fabrics.

- Double jersey circular knitting machine

Ordinary double jersey circular knitting machine is also called cotton wool machine, multi-function machine, universal knitting machine, etc. It also has (1+1) needle path, (2+2) needle path, (2+4) needle path and rib knitting machine. (4+4) Needle path. The newly introduced knitting circular knitting machine companies, in order to produce more varieties of patterns, mostly use (2+4) needle circular knitting machines, which use the mutual arrangement and combination of triangles and knitting needles and yarn arrangements to knit Production of new knitted fabrics.

- Double jacquard knitting circular knitting machine

Double jacquard knitting circular knitting machine has two types: small jacquard machine and large jacquard machine.

1) Small double jacquard knitting circular knitting machine

Same as the small single jacquard knitting circular knitting machine, with small double-sided jacquard knitting machines such as ordinary rib, double-sided and transfer loops.

2) Large double jacquard knitting circular knitting machine

Same as large-scale single jacquard knitting circular knitting machine, with large-scale jacquard double-sided jacquard and transfer jacquard machines.

In addition, there are some special large circle machines, namely transfer large circle machine (including transfer rib machine, single-sided transfer large circle machine, double-sided transfer large circle machine, etc.), double terry machine (that is, the fabric has a loop effect on both sides of the fabric ), single-sided machine on the tube (ie double-reverse round machine)