Specifications for the maintenance and maintenance of large circular knitting machines in the workshop

Purpose

In order to make the daily maintenance and maintenance of the company’s production equipment have rules to follow, so as to maintain the normal operation of the production equipment and reduce the incidence of equipment failures, these regulations are specially formulated.

2. Scope of application

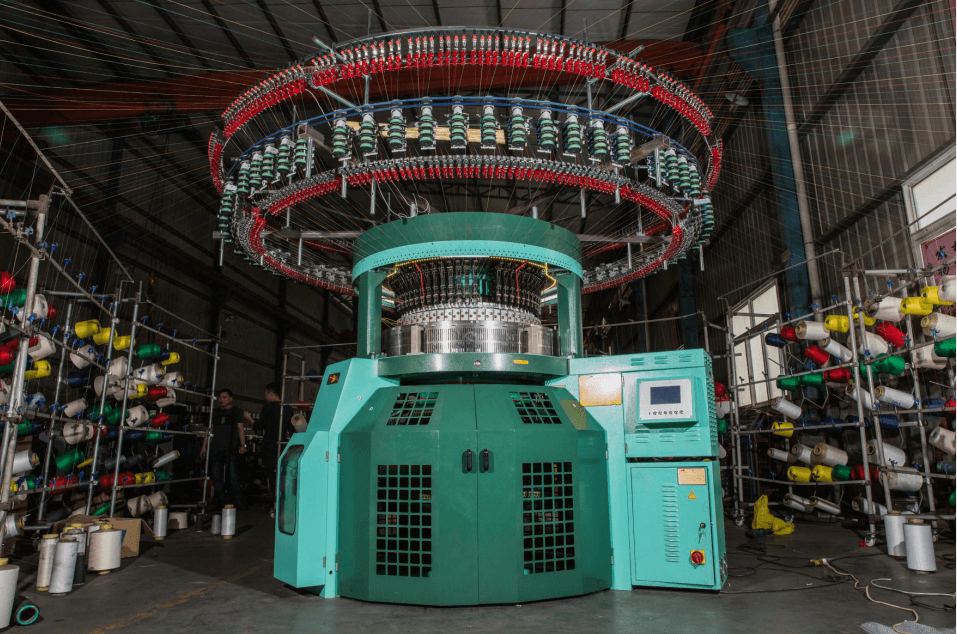

Workshop large circular knitting machine.

3. Content

3.1 Responsible person

The technical group of the production department and the car operator are respectively responsible for the maintenance work. The technicians of the technical team often inspect the workshop every day, communicate with the shift workers, and conduct a comprehensive and detailed inspection of the machine once a month, and deal with problems in a timely manner.

3.2 Day Warranty

3.2.1 Remove the lint and fluff attached to the surface of the creel and machine table every shift. Keep the knitted components and the take-up device clean.

3.2.2 Check the self-stop device and safety device every shift, if there is any abnormality, immediately dismantle or replace it.

3.2.3 Check the active yarn feeding device every shift, and remove it for repair or replace it immediately if there is any abnormality.

3.2.4 Check the oil level mirror of the crankshaft and the oil level pipe of the fuel injector every shift.

3.3 weeks maintenance

3.3.1 Clean the yarn feeding speed adjusting the aluminum plate, remove the lint accumulated in the plate, and check whether the tension of the conveyor belt is normal.

3.3.2 Check whether the belt tension of the transmission system is normal and whether the transmission is stable.

3.3.3 Check the operation of the cloth winder.

3.4 months warranty

3.4.1 Remove the upper and lower plate triangle seats and remove the accumulated lint.

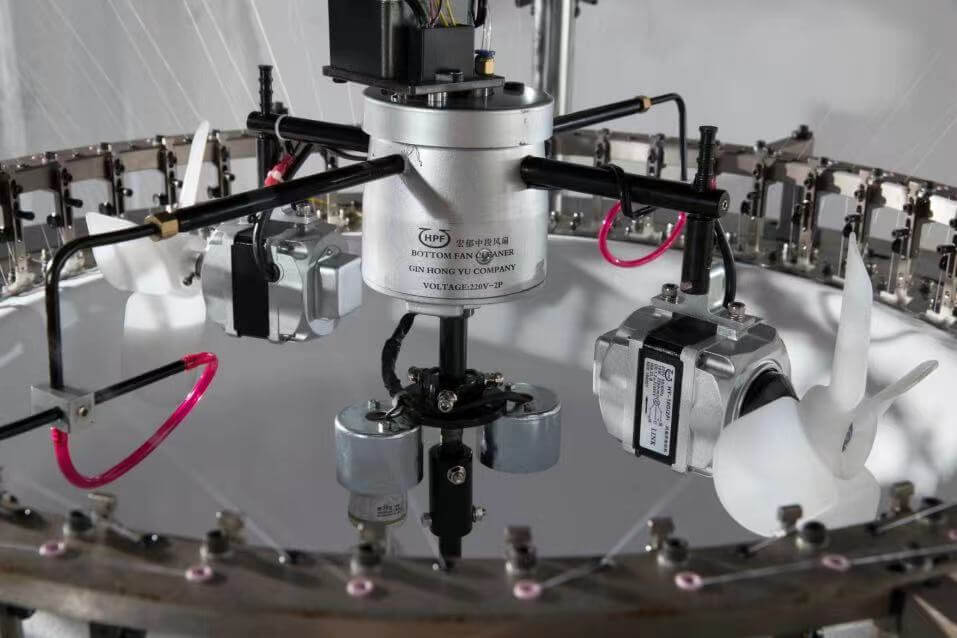

3.4.2 Clean the dust removal fan and check whether the blowing direction is correct.

3.4.3 Clean the lint in all electrical accessories.

3.4.4 Review the performance of all electrical accessories (including self-stop system, safety alarm system, detection system).

3.5 half-year warranty

3.5.1 Washing machine. Thoroughly clean the upper and lower dials, including the knitting needles and sinkers, select all the knitting needles and sinkers, and replace them immediately if damaged.

3.5.2 Clean the fuel injector and check whether the oil circuit is unblocked.

3.5.3 Clean and check the positive yarn accumulator.

3.5.4 Clean the lint and oil stains in the motor and transmission system.

3.5.5 Check whether the waste oil collection oil circuit is unblocked.

3.6 Maintenance and maintenance of main parts of circular knitting machine

3.6.1 Cleaning the needle groove can prevent dirt from entering the knitted fabric with the needle. The cleaning method is: replace the yarn with a low-grade or waste yarn, turn it on at high speed, and inject a large amount of needle oil into the needle cylinder while running Add oil until the dirty oil completely flows out of the tank.

3.6.2 Check whether the knitting needles and sinkers in the needle cylinder are damaged, and the damage should be replaced immediately; if the quality of the cloth surface is too poor, it should be considered whether to renew all.

3.6.3 Check whether the width of the needle groove of the needle cylinder is the same distance (check whether there are straight stripes on the woven fabric surface) and whether the needle groove wall is defective. If the above problems are found, they should be repaired or updated immediately.

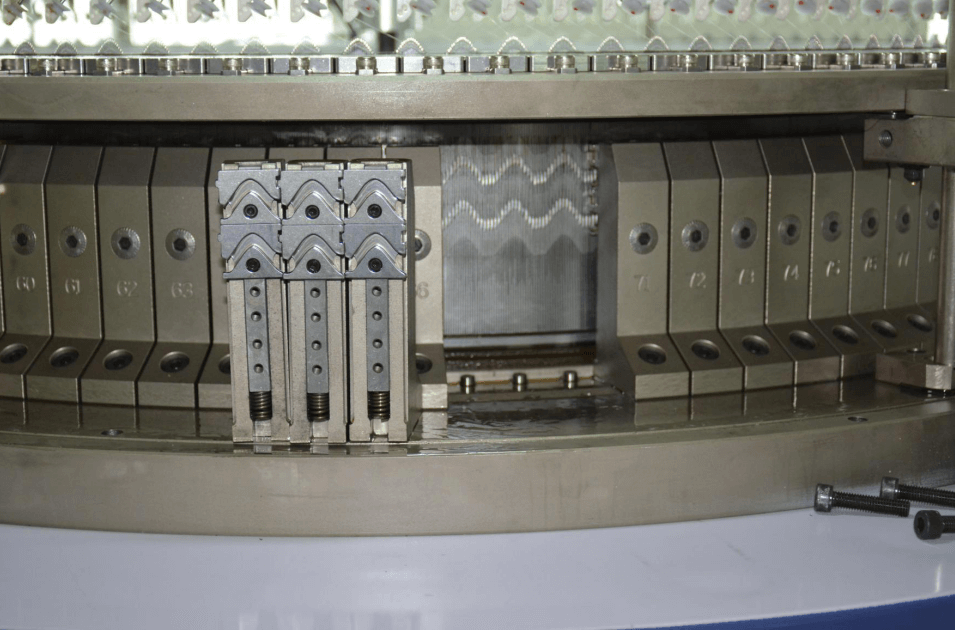

3.6.4 Check the wear of the triangle and confirm whether the installation position is correct and whether the screws are locked.

3.6.5 Check and correct the installation position of each yarn feeder, if any wear is found, it should be replaced.

3.6.6 Correct the installation position of the narrowing triangle of each yarn feeding port so that the length of each loop of the weaving fabric is uniform with each other.

3.7 The lubrication method, oil and lubrication execution of the machine

3.7.1 Lubrication method and oil

3.7.1.1 The oil level mirror of the large chainring should be checked every day. If the oil level is lower than 2/3, the oil should be refueled manually. Use 140#–160# engine oil. During the half-year maintenance, if oily deposits are found, they should be replaced immediately.

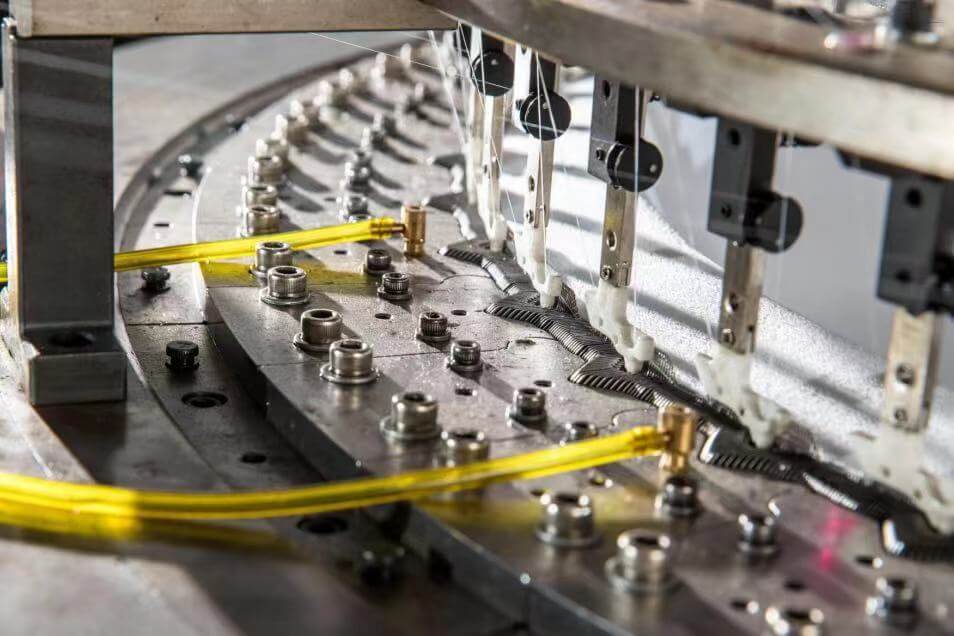

3.7.1.2 Dating transmission gear should be checked once a month and grease should be added. Use No. 4 bentonite grease (commonly known as snow oil).

3.7.1.3 During the half-year maintenance, check all transmission bearings and add grease. Use high-temperature grease.

3.7.1.4 The lubrication of all knitting machines (including oil injection machines) must use special needle oil for high-speed circular knitting machines, or special lubricants for disc knitting machines.

3.7.2 Lubrication execution

Accurately grasp the oil type and lubrication time of each part, so that each designated part of the machine in the whole plant can be lubricated with the specified type and amount within the specified time.

3.8 Maintenance and maintenance of power distribution system

The power distribution system is the power source of the knitting machine. Strict regular maintenance must be implemented to avoid unnecessary failures.

3.8.1 Check the machine for leakage.

3.8.2 Check whether the switch button is invalid.

3.8.3 Check whether the detectors everywhere are safe and effective at any time.

3.8.4 Check the circuit for wear and disconnection.

3.8.5 Check the inside of the motor, clean the dirt attached to each part and add oil to the bearing.

3.9 Precautions for shutdown and storage

The machine is maintained and maintained in accordance with the six-month maintenance program. Lubricating oil is added to the knitted components; oil-proof is added to the knitting needles and sinkers. Finally, the machine is covered with oilcloth soaked in needle oil and sealed in a dry and clean place.

3.10 Storage of machine parts and spare parts

3.10.1 The normal storage of commonly used and vulnerable parts is an important guarantee for the continuity of production. The general storage environment should be a cool, dry place with little temperature difference. The specific storage methods are as follows:

3.10.2 Storage of syringes and dials

First, clean the syringe, put in engine oil and wrap it with oilcloth, and put it in a wooden box to avoid bumps and deformation.

Use compressed air to remove the oil in the syringe before use, and add needle oil when using it.

3.10.3 Storage of triangle

Sort the triangle into the warehouse, store it in a box and add needle oil to prevent it.

3.10.4 Storage of knitting needles and sinkers.

New needles and sinkers should be placed in the original packaging box, do not remove the sealing strip.

Old needles and sinkers must be cleaned and inspected, and the damaged ones must be picked out, stored in a box, and put in needle oil prevention. Note:

All knitting parts (including knitting needles, sinkers, cams and needle cylinders) should only be cleaned with knitting oil, so as not to affect the normal performance of other parts of the machine.

The spray lubrication system of the circular knitting machine must provide clean and dry compressed air without moisture. Therefore, the air compressor unit should be equipped with a water-proof and dehumidifying device. At the same time, it should be ensured that the high-pressure air output by the pipeline is free of dirt and debris. The storage time of parts should not be too long and should be checked regularly.

4. Record

4.1 “Maintenance Record Form”

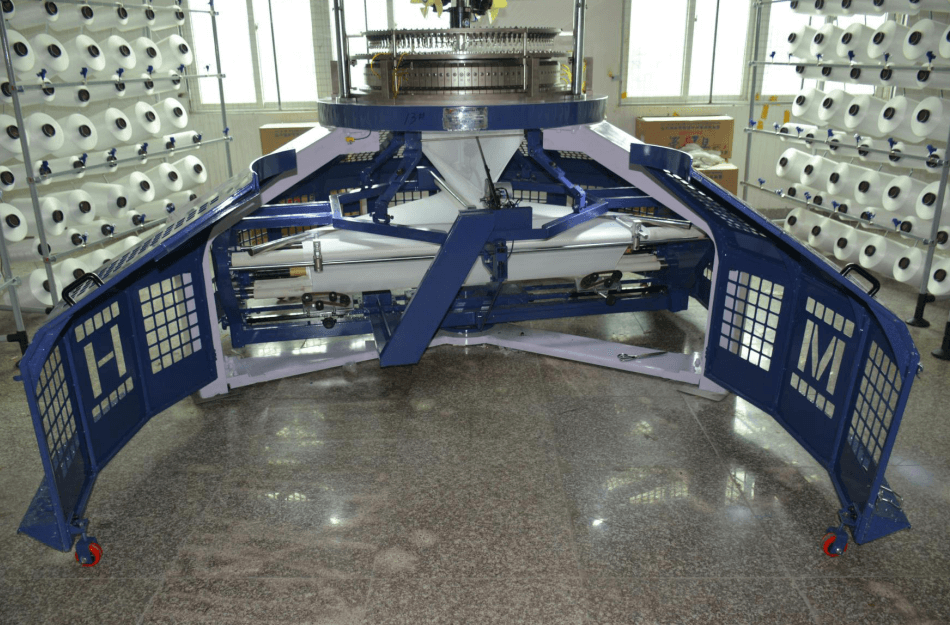

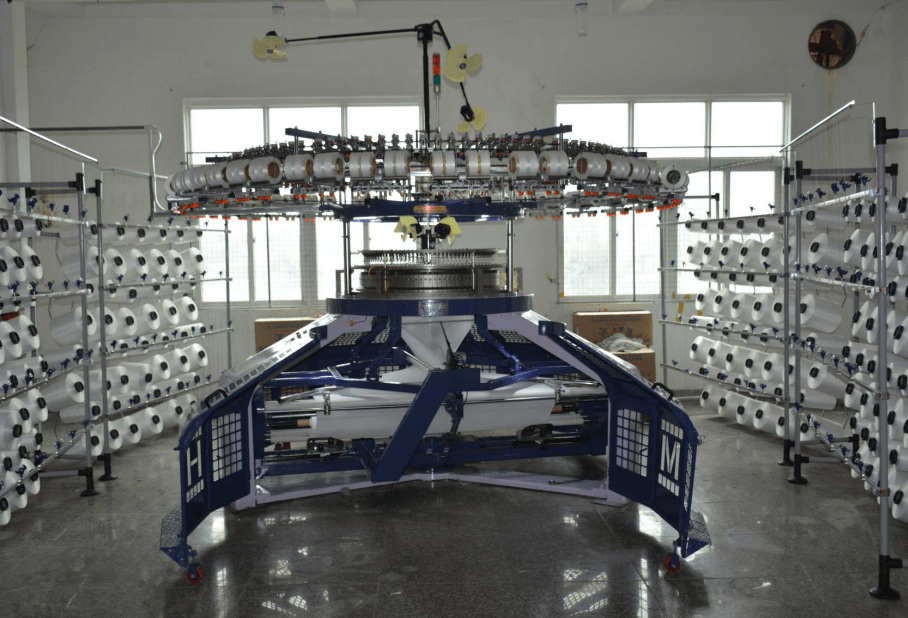

Double Jersey Rib Interlock Circular Knitting Machine install with two tracks CAMs on the dial plate and four tracks CAMs in the cylinder, through adjusting

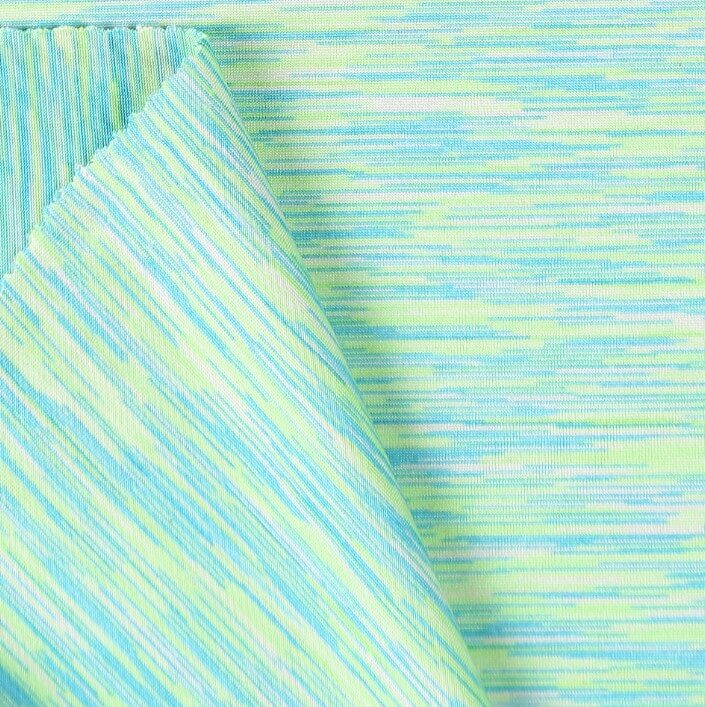

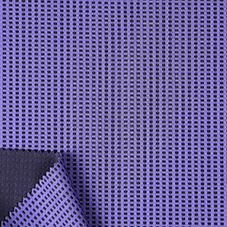

the position of CAMs, the machine can knit various fabrics such as twill, interlining fabric, air layer fabrics, little jacquard interlayer gasket, bubble-bubble, crape, knitting cloth, pique fabric, etc. If the double jersey machine installs lycra feeders and attachments, it can also knit stretch double jersey fabric. All types of fabrics produced by the machine are widely used in producing underwear, coat fabrics, varied sportswear, and fashion fabrics.

•The machine is suitable for long and short fabric, rib fabric, and jacquard fabric, and yarn socket can be independent with spandex device to weave elastic double fabric 2+4 distance

•The machine can weave complex fabric with changed texture and lower material high-class clothing.

The cams on the lower and upper dials of this machine feature a closed-track design with cams of knit, tuck, and miss. The yarn feeder can be adjusted independently allowing knitting of elastic double jersey fiber by installing an additional Lycra attachment. Also comes equipped with varying types of cylinder, easy and quick to transfer, enabling this machine to meet the never-ending demands of the knitting market.

Weight: 2800kg

Condition: new

Knitting type: circular knitting

Application: 24”-68”

Gauge:15G-44G

System support:72F-272F

Needle: China/ Germany

Speed: 16-24r/m

Warranty: 1 year

Lead time:30 days

Stitch Density: High speed

Control system: Hanma Drive type: Sea flight

Related Product

high leg DOUBLE JERSEY OPEN WIDTH KNITTING MACHINE

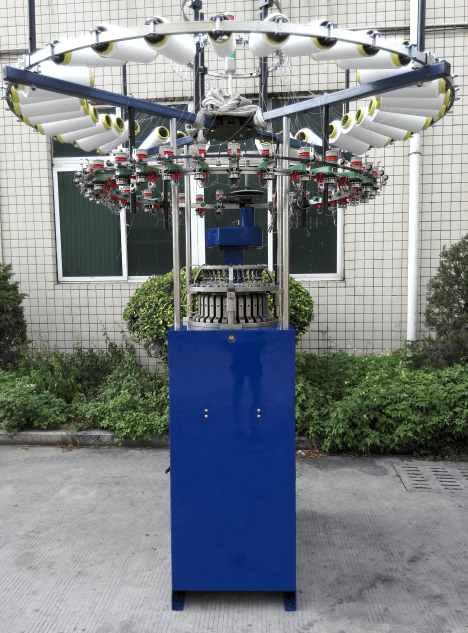

HIGH-SPEED Small size RIB Circular KNITTING MACHINE

Double terry circular knitting machine

Velvet Shearing Circular Knitting Machine

High Speed Rib Knitting Machine

PILE LOOP SHEARING CIRCULAR KNITTING MACHINE

DOUBLE JERSEY Circular KNITTING MACHINE

DOUBLE JERSEY OPEN WIDTH KNITTING MACHINE

Related Article

What is heat-setting knowledge?

circular knitting machine guide

what is Basic knowledge of circular knitting

What is the Knowledge of knitted fabrics

what is the kind of circular knitting machine

Circular knitting machine basic operation knowledge

Read moreCircular knitting machine basic operation knowledge

circular knitting machine price

Contract us

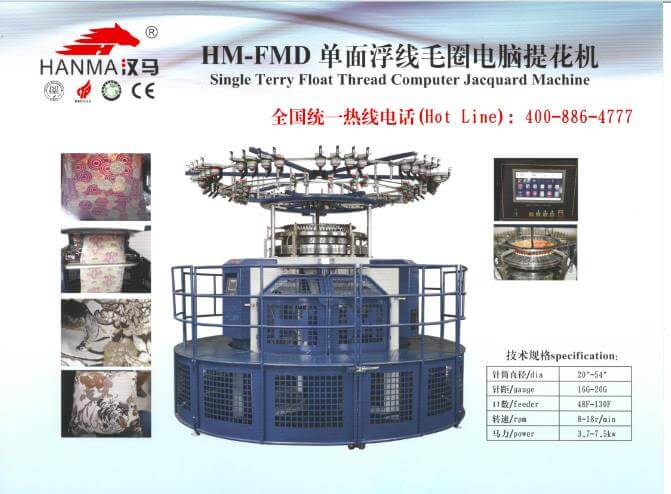

| Condition: New | Product Type:fabric | Type:Circular | Production Capacity:250-750kg |

| Place of Origin: Fujian China (Mainland) | Brand Name:HANMA (circular knitting machine) | Model Number:HM-DF4 (circular knitting machine) | Power(W):5.5kw (circular knitting machine) |

| Knitting Style: knitted | Knitting Method: Double | Computerized: No | Weight:2.5TON |

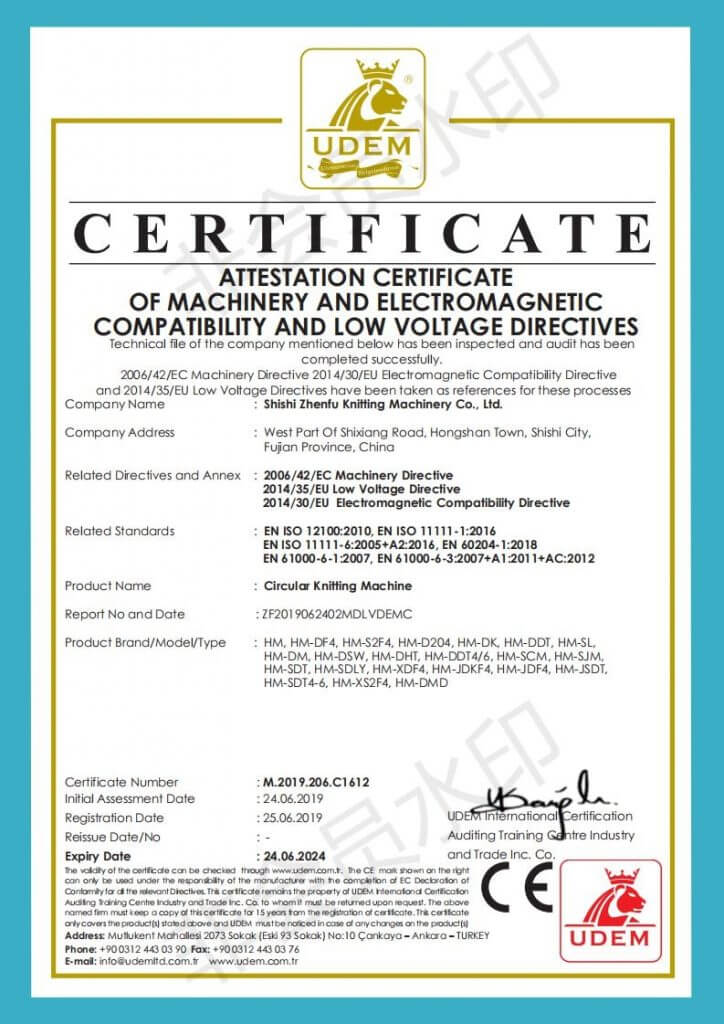

| Dimension(L*W*H):2.35*2.28*2.28M | After-sales Service Provided:Engineers available to service machinery overseas | speed:0-30RPM | Certificate: CE |

| machine type: double jersey | turn way: anticlockwise | fabric function:sports garment |

Company Profile

Zhenfu Knitting Machinery Co., Ltd. is a professional enterprise specializing in manufacturing machines, woven products, and apparel. We are also engaged in the production and design of fabrics and large diameter circular knitting machines for woof weaving and knitting. We have three trademarks — “HANMA”, “LUHU”, “ZHENFU”.We introduced foreign advanced computer process equipment and test and measurement instruments. We also research information reflection from consumers for stratifying customers’ different demands. We have a group of engineer technicians with rich experience. They can develop new products according to customers’ specifications. We are based on the enterprise tenet of “Credit, Factualism, and Innovation” and persist in the management concept of “Quality is the Base and Credit is the First”. We can supply top-ranking products and perfect after-sales services to our customers. We have taken root in a vehemently competing market of diameter circular knitting machines. Our company was awarded ISO9001 certificate in 2003. We have developed into a production factory with a certain scale. We offer large diameter circular knitting machines, including rib universal machines, large high-speed and single-sided jacquard cylinders, high-speed and single-sided large diameter circular knitting machines, back-to-face packed pole loop machines, and single-sided sanitary clothes. We welcome all clients to contact us.

| No | Description | Supplier | Brand | Quantity |

| 1 | Insert flake type cylinde&dlar(Germany metal) | Hanma | China | 1 unit |

| 2 | Needles | Groz-beckert | Germany | 1 Set |

| 3 | Positive storage yarn feeders | Hanma | China | 1 Unit |

| 4 | Oiling lubricator | Hongsheng | China | 1 Set |

| 5 | Yarn Creel | Hanma | China | 1 Set |

| 6 | One way take-down device | Hanma | China | 1 Set |

| 7 | Invertor | Sunyue | China | 1 Set |

| 8 | Fabric Spreader equipment | Hanma | China | 1 Set |

| 9 | Cams | Japan | 1 Set | |

| 10 | Digital indicator control panel | Hanma | China | 1 set |

| 11 | Automatic dust fans with blower equipment. | San song | China | 1 set |

| 12 | Radar type round 360’ clear dust equipment | San song | China | 1 set |

| 13 | Spare tools | |||

| 14 | Operation manual for invertor & controller panel | |||

| 15 | Extra Spare parts : (a) 100pcs needles (b)Feeders 1pcs (c)Air blower gun 1 set (d)Fuse 4pcs (e) Yarn carrier 1pcs (f)Needle oil 1 liter |

*Features:

1.Most of the structures and main parts are produced by an advanced processing center, which ensures precision and accuracy. Interlock fabric needs very high precision, Hanma machine can help you to reach the beautiful surface, to catch the high-end customer.

2.All cams are made of special alloy steel and processed by CNC under CAD / CAM and heat treat. The process guarantees the great hardness and wear-proof.

3.Use GROZ-BECKERT needles and KERN-LIEBER’S sinkers which ensure the fabric quality and long life of the machine.

4.The fabric knitted can be widely used for many fields, such as diving fabric, yoga fabric, underwear fabric, sandwich fabric, car seat fabric, and all kinds of double jersey fabric.

Related Product

Related Article

Rare earth heating fibers

Textile fabric width control

Several types of regenerated fibers that are easily confused.

Read moreSeveral types of regenerated fibers that are easily confused.

Key technologies for double-sided circular knitting machine needle plate calibration

Read moreKey technologies for double-sided circular knitting machine needle plate calibration

How a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)

Read moreHow a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)