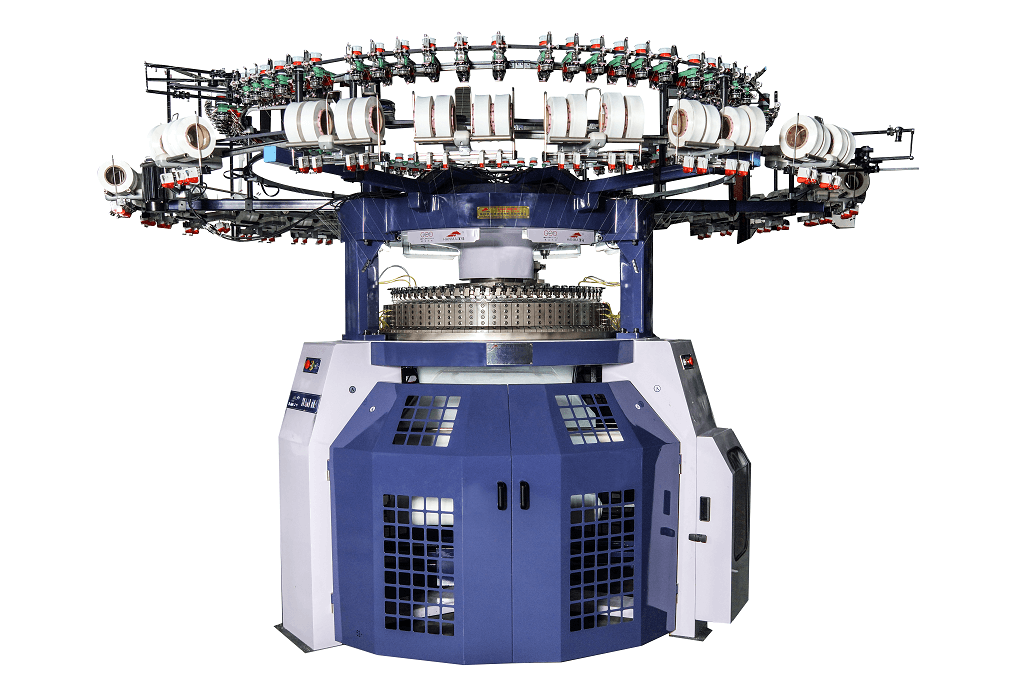

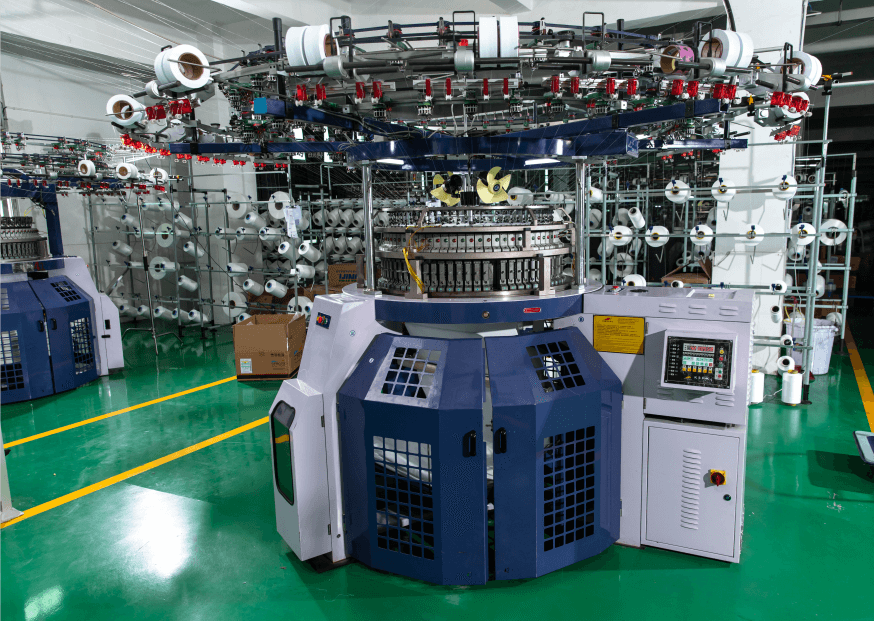

What is HANMA CIRCULAR KNITTING MACHINE TEST SERVO YARN FEEDING SYSTEM?

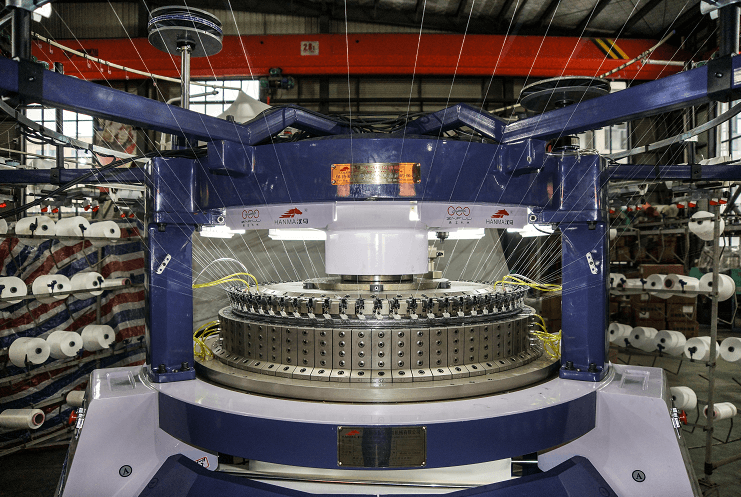

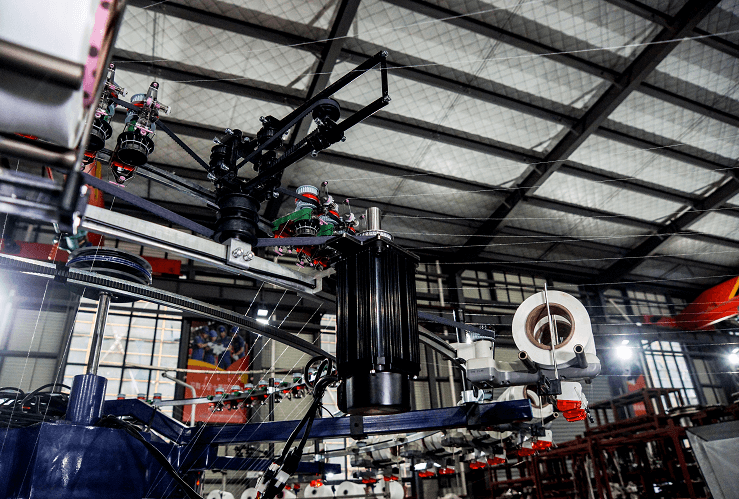

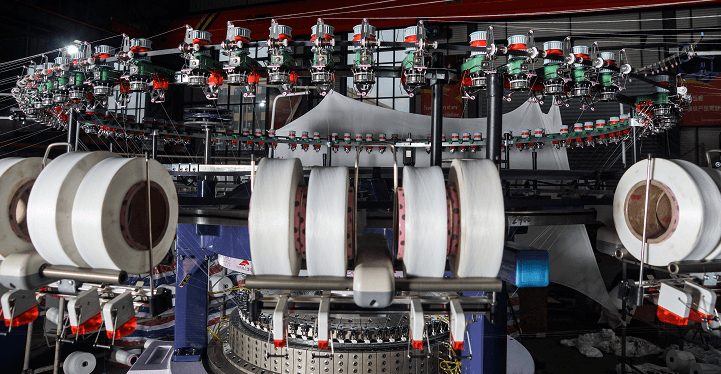

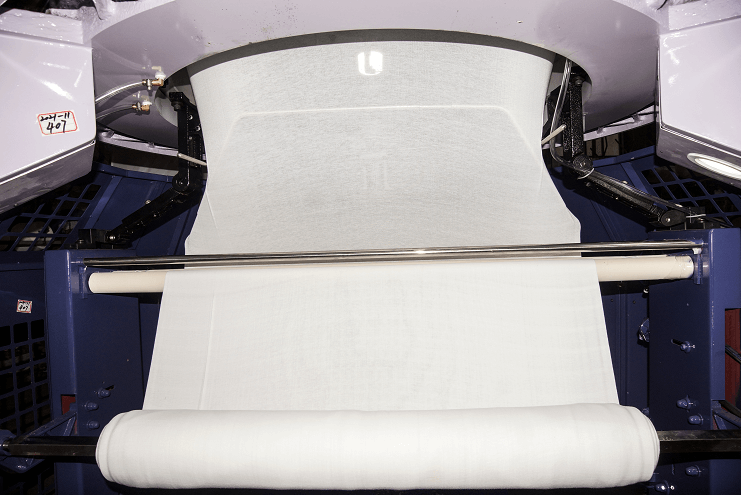

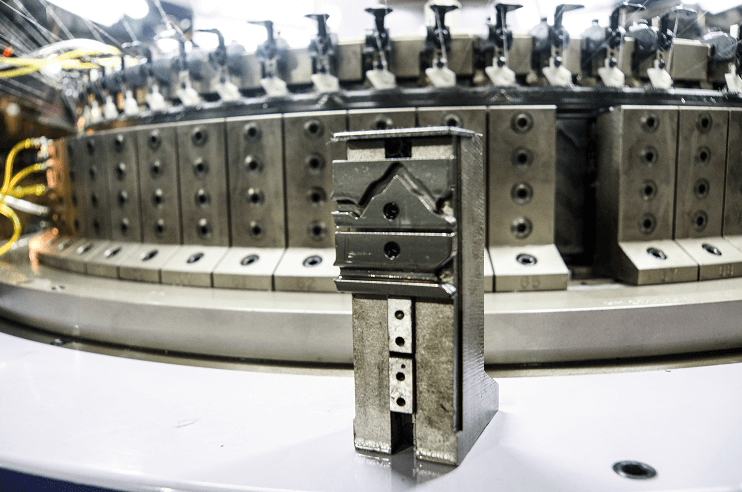

A circular knitting machine, scientific name knitting circular weft knitting machine or knitting circular weft knitting machine, is common textile equipment. In the yarn feeding mechanism of the traditional big round machine, the shaft of the yarn feeding aluminum disc and the main power motor are driven by the synchronous belt and the synchronous wheel, the main power motor drives the yarn feeding aluminum disc to rotate, and the yarn feeding aluminum disc drives the yarn conveyor to rotate through the synchronous wheel. When the large circular machine works, it is necessary to monitor the length of the conveyed yarn. The yarn length is an important index to ensure fabric quality. In the above yarn feeding structure, the yarn length adjustment requires mechanical engineers to replace yarn feeding aluminum discs of different sizes with experience, which not only requires high skills of engineers, but also cumbersome mechanical steps for replacing yarn feeding aluminum discs. At the same time, the yarn feeding mechanism of the traditional large circular machine needs an external yarn measuring device for yarn length calculation, which not only increases the cost of production equipment but also because the yarn measuring device relies on the electric pulse signal transmitted by the yarn measuring lens. Generally, there are 30 electric pulses in a circle, and the calculation accuracy is one-thirtieth of the outer circumference of the yarn conveying wheel, so the yarn length calculation is not accurate enough.

Technical realization elements:

One of the purposes of the invention is to overcome the above shortcomings and provide a large circular machine servo yarn feeding method with yarn length calculation. Setting a yarn length calculation module in the yarn feeding servo driver can not only reduce the hardware cost of the external yarn tester, but also improve the accuracy of yarn length calculation and facilitate use and management.

In order to solve the above technical problems, the invention provides a large circular machine servo yarn feeding method with yarn length calculation, which comprises the following steps:

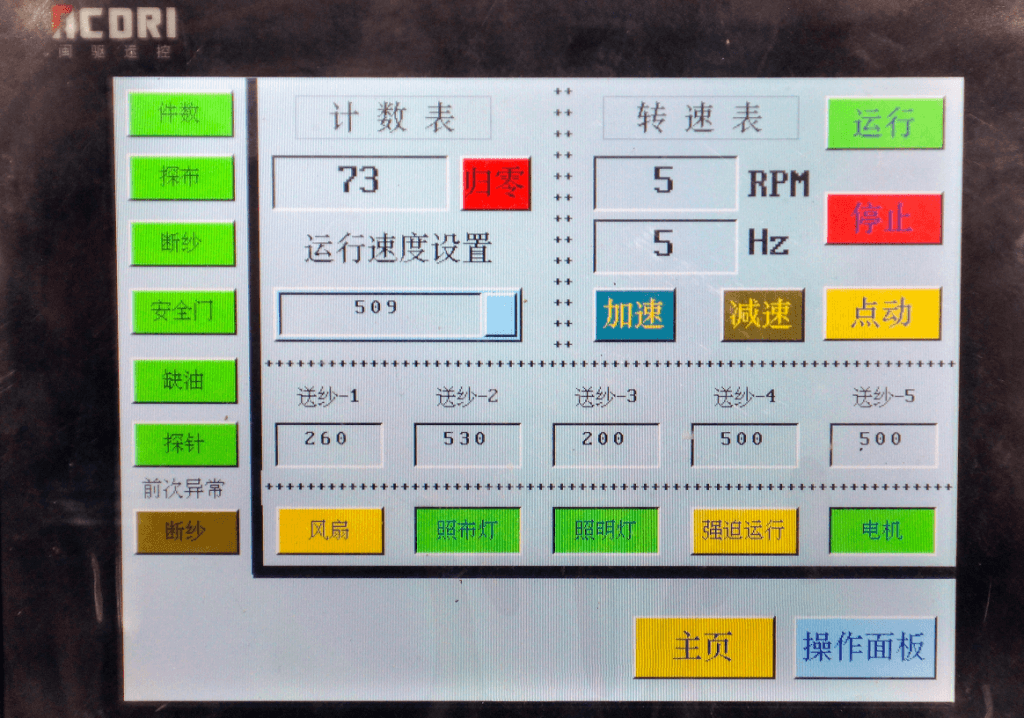

Inputting the desired yarn length value, yarn length range value and total needle value through the touch screen, the yarn feeding servo driver sets the electronic gear ratio according to the desired yarn length value, and saves the yarn length range value and total needle value at the same time;

The hollow shaft encoder follows the main shaft of the large circular machine, converts the operation speed and angle of the main shaft of the large circular machine into pulse signals, and feeds back to the yarn feeding servo driver;

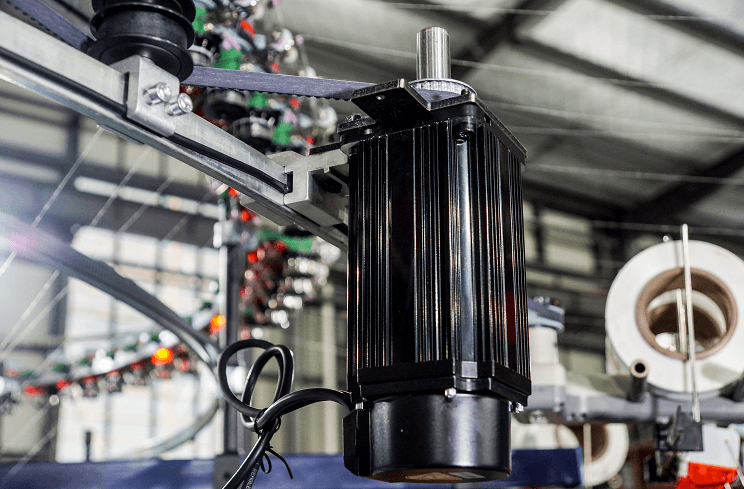

The yarn feeding servo driver controls the pulse command sent to the yarn feeding servo motor according to the feedback pulse signal and the electronic gear ratio;

The yarn feeding servo motor rotates according to the received pulse command and drives the yarn feeding wheel to run;

The yarn feeding servo driver calculates the actual yarn length value and determines whether it exceeds the yarn length range;

The touch screen displays the actual yarn length value and alarm information according to the calculation result of yarn feeding servo driver.

The technical scheme of the application adopts a servo yarn feeding system to replace the yarn feeding aluminum disc driving the rotation of the yarn feeder and the driving gear transmission mechanism with a servo motor. By setting the yarn length on the touch screen, the electronic gear ratio of the servo driver is changed, which is more intuitive for the operator. At the same time, it is more convenient and faster than the traditional mechanical structure to replace the yarn feeding aluminum disc and reduce the labor cost.

Further, the large circular machine servo yarn feeding method with yarn length calculation comprises a plurality of yarn feeding servo drivers and a plurality of yarn feeding servo motors, and the yarn feeding servo driver corresponds to the yarn feeding servo motor one by one.

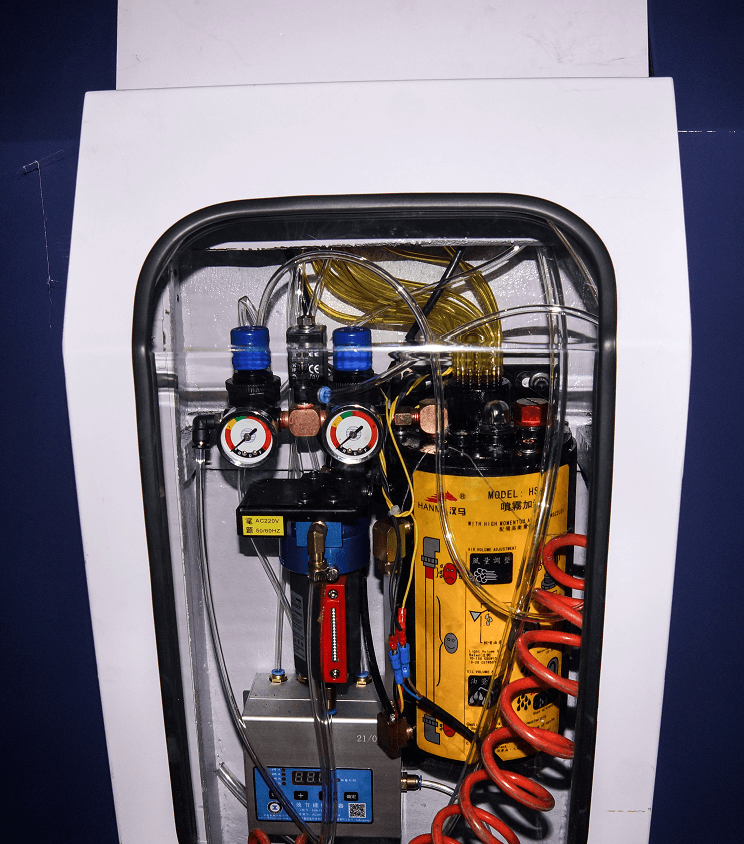

Further, the yarn feeding servo driver is arranged in the yarn feeding servo system control cabinet, which comprises a yarn feeding servo driver, a control line, a power encoder line, a leakage protector, a switching power supply, a terminal strip and an incoming terminal.

Further, the “yarn feeding servo driver calculates the actual yarn length value and determines whether it exceeds the yarn length range”, including the following steps:

The yarn feeding servo driver receives the counter signal sent by the main shaft of the large circular machine;

Judge the parity of the total number of received counter signals;

If the total number of counter signals received is odd, clearing the encoder pulse value of the yarn feeding servo driver;

If the total number of counter signals received is an even number, save the encoder pulse value of the yarn feeding servo driver and calculate the actual yarn length value this time. The calculation formula is: where l is the actual yarn length value this time, R is the yarn feeding wheel radius, q is the saved encoder pulse value this time, P is the driving pulse value required for one revolution of the yarn feeding servo motor, and N is the total needle value; Judge whether the actual yarn length value is within the set yarn length range. If the actual yarn length value exceeds the yarn length range, carry out alarm processing;

Repeat the above steps to calculate the actual yarn length value for many times, take the average value according to the set value, and calculate the average yarn length value after removing the maximum yarn length and the minimum yarn length.

In the technical scheme of the application, the yarn length calculation module is built in the yarn feeding servo driver to collect the incremental pulse signal to calculate the yarn length value, which not only saves the equipment cost of the traditional external yarn tester, but also because the encoder of the servo is usually 2500 electric pulses in a circle, and the calculation accuracy is one 2500 of the outer circumference of the yarn feeding wheel, the calculated yarn length is more accurate, It can intuitively monitor and alarm the real-time yarn length value, which greatly improves the work efficiency.

Accordingly, the application also provides a large circular machine servo yarn feeding system with yarn length calculation, which comprises a touch screen, a hollow shaft encoder, a yarn feeding servo driver and a yarn feeding servo motor, wherein,

The touch screen is used to input the expected yarn length value, yarn length range value and total needle value, and display the actual yarn length value and alarm information according to the calculation result of the yarn feeding servo driver;

A hollow shaft encoder for following the main shaft of the large circular machine, converting the operation speed and angle of the main shaft of the large circular machine into a pulse signal and feeding back to the yarn feeding servo driver;

A yarn feeding servo driver for setting an electronic gear ratio according to the desired yarn length value and saving the yarn length range value and the total needle value; Controlling a pulse command sent to the yarn feeding servo motor according to the feedback pulse signal and the electronic gear ratio; It is used to calculate the actual yarn length value and judge whether it exceeds the yarn length range;

The yarn feeding servo motor is used to rotate according to the received pulse command and drive the yarn feeding wheel to run.

Further, the yarn feeding servo driver calculates the actual yarn length value and determines whether it exceeds the yarn length range, including the following steps:

The yarn feeding servo driver receives the counter signal sent by the main shaft of the large circular machine;

Judge the parity of the total number of received counter signals;

If the total number of counter signals received is odd, clearing the encoder pulse value of the yarn feeding servo driver;

If the total number of counter signals received is an even number, save the encoder pulse value of the yarn feeding servo driver and calculate the actual yarn length value this time. The calculation formula is: where l is the actual yarn length value this time, R is the yarn feeding wheel radius, q is the saved encoder pulse value this time, P is the driving pulse value required for one revolution of the yarn feeding servo motor, and N is the total needle value; Judge whether the actual yarn length value is within the set yarn length range. If the actual yarn length value exceeds the yarn length range, carry out alarm processing;

Repeat the above steps to calculate the actual yarn length value for many times, take the average value according to the set value, and calculate the average yarn length value after removing the maximum yarn length and the minimum yarn length.

Further, the large circular machine servo yarn feeding system with yarn length calculation comprises a plurality of yarn feeding servo drivers and a plurality of yarn feeding servo motors, and the yarn feeding servo driver corresponds to the yarn feeding servo motor one by one.

Further, the yarn feeding servo driver is arranged in the yarn feeding servo system control cabinet, which comprises a yarn feeding servo driver, a control line, a power encoder line, a leakage protector, a switching power supply, a terminal strip and an incoming terminal.

Accordingly, the application also provides a large circular machine, comprising a large circular machine servo yarn feeding system with yarn length calculation according to any one of claims 5-8.

Related Product

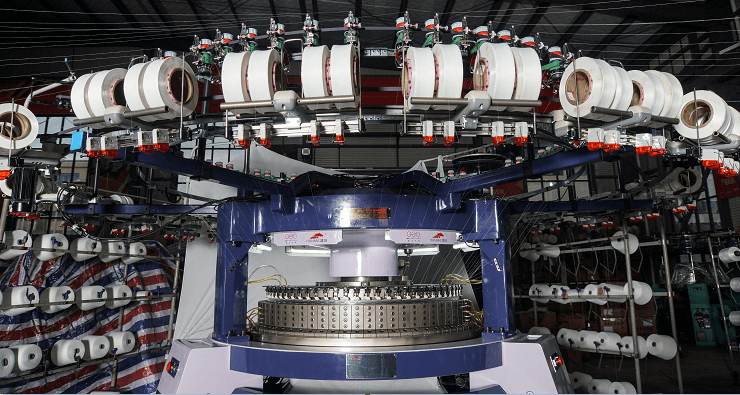

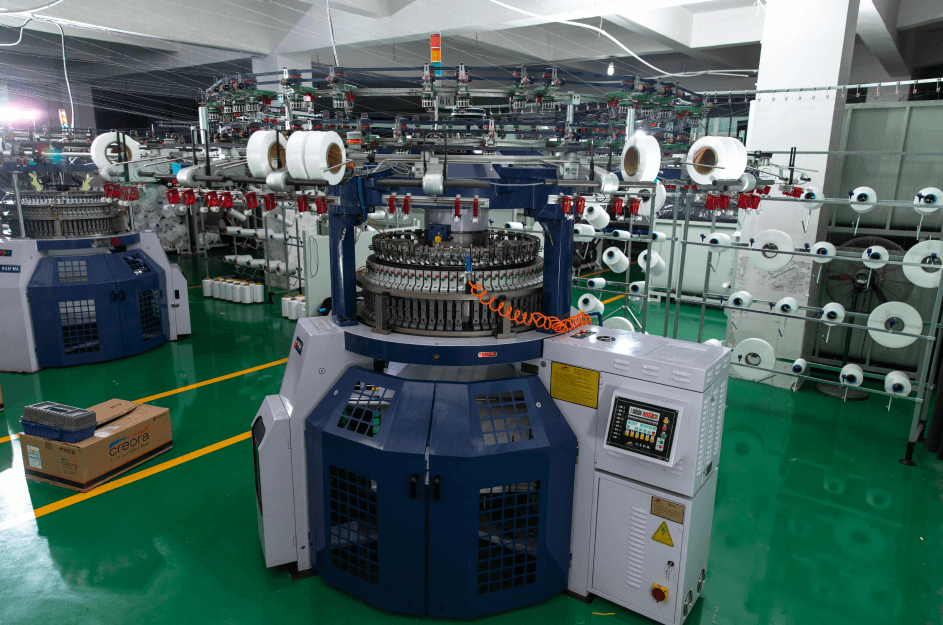

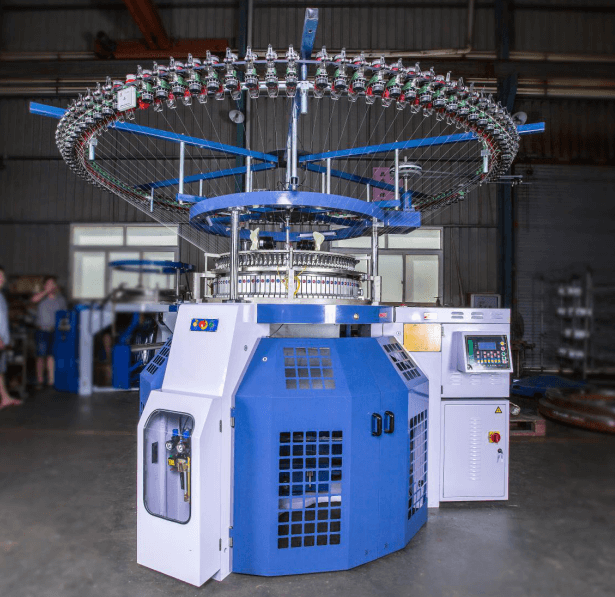

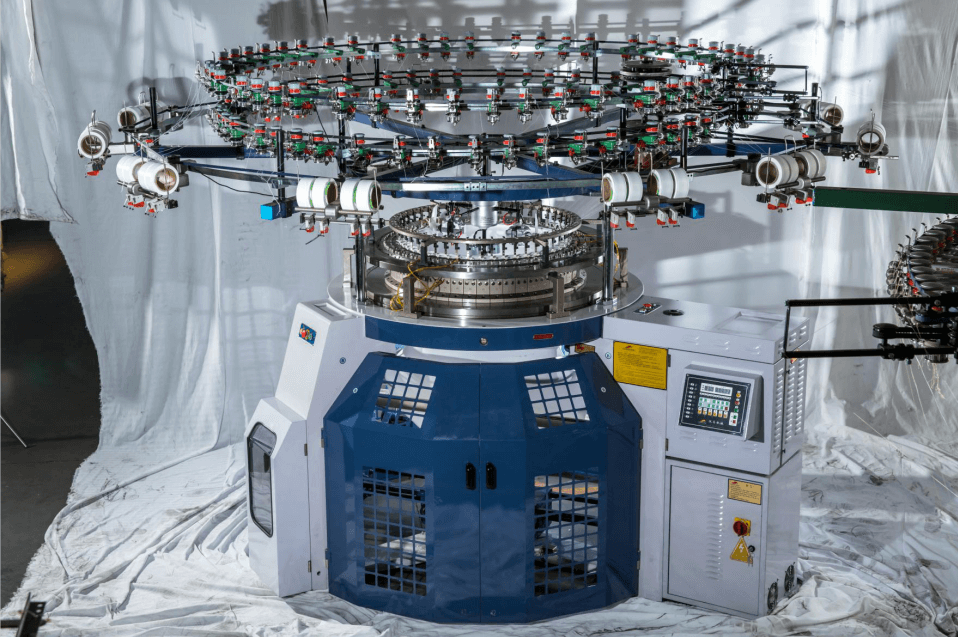

Double Jersey Jacquard (utopian) Circular Knitting Machine

SINGLE JERSEY KNITTING MACHINE

SINGLE TERRY CIRCULAR KNITTING MAchiNE

SINGLE JERSEY OPEN WIDTH circular KNITTING MACHINE

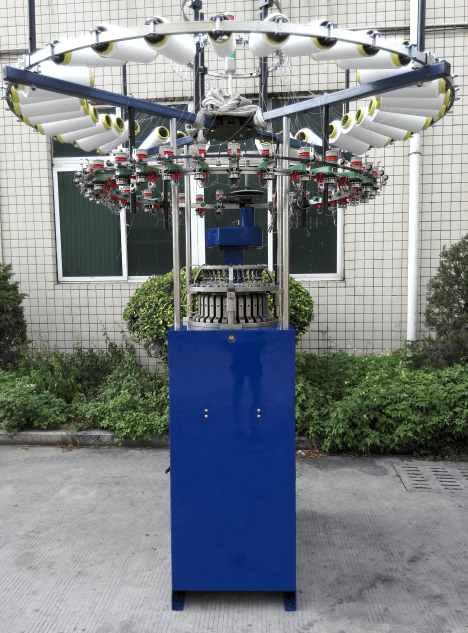

SMALL SIZE SINGLE JERSEY CIRCULAR KNITTING MACHINE

SINGLE JERSEY JACQUARD circular KNITTING MACHINE(UTOPIAN)

Related Article

Rare earth heating fibers

Textile fabric width control

Several types of regenerated fibers that are easily confused.

Read moreSeveral types of regenerated fibers that are easily confused.

Key technologies for double-sided circular knitting machine needle plate calibration

Read moreKey technologies for double-sided circular knitting machine needle plate calibration

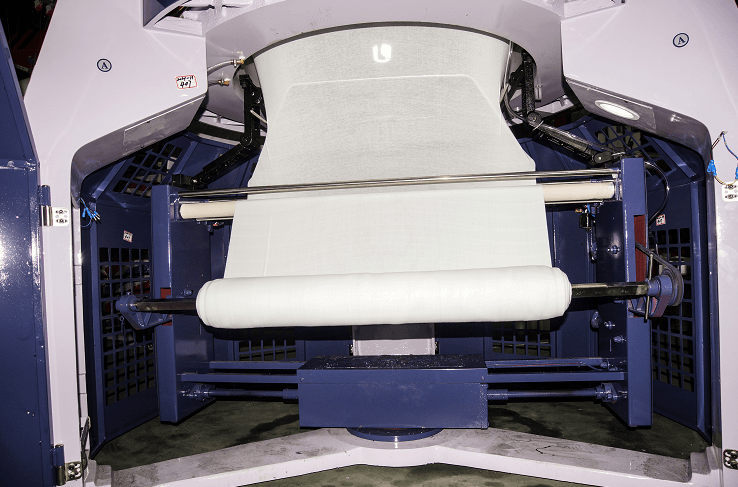

How a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)

Read moreHow a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)