Fluff and Polish

Raising and buffing knitted fabrics is a kind of post-treatment processing method. Raising fabrics include pure cotton terry, pure cotton terry cloth, t/c Terry and terry cloth, CVC Terry, etc.

The customary distinction method is: the terry cloth has small loops and large loops. This kind of terry fabric fuzzing uses steel needle rollers to mechanically cut the terry structure and produce fuzz. There are many weaving structures of frosted fabrics. They use the mechanical friction between carbon fibers of the frosting machine and sandpaper to produce uniform short fluff on the surface of the fabric.

Influencing factors and precautions

The fabrics with great influence are mainly t/c fabrics with low gram weight, loose weaving structure, and high horizontal and vertical elasticity. They are not soft enough, either they can’t afford to pile up, or they are buckled (the Terry is lifted, but it is not cut). The auxiliary factory will only sell a single flocking agent, and I don’t know the root cause of poor flocking.

Fluffing agent: it is well known in the industry that low yellowing film is compounded with less than 10% dimethylsilicone oil lotion (also known as fluffing oil). This fluffing agent formula can only provide a smooth and soft feel, and has no effect on this kind of buckle fluffing fabric.

Cotton Terry and terry cloth with tight weaving structure, fluffy film, and a little high ammonia silicone oil and dimethylsilicone oil lotion (fuzzing oil) can enrich hairiness once.

Do not use amino silicone oil for t/c fabrics. The resilience and viscosity of amino silicone oil will have a negative effect on flocking, which will increase the softness, smoothness and elasticity of the fabric, and increase the probability of buckle and tear of the flocked fabric. Sometimes it feels that the fabric is very soft, but it can’t afford to pile or buckle.

The correct softening method of t/c fabric is: the film is mixed with dimethyl silicone oil lotion, and then combined with a little multifunctional finishing agent (also known as moisture absorption and sweat wicking finishing agent).

The pile fabric with low gram weight must not be soft and slippery, which will greatly reduce the strength of the fabric, tear the fabric when raising, and the loose elasticity of the fabric will increase, which is easy to hang; Just add a little fluffy and smooth feel; Heavy fabrics can be soft and smooth, which can reduce the number of fuzzing tracks.

For various reasons, the textile factory did not use pile yarn to weave, resulting in the phenomenon of no pile or buckle, but it is different from the phenomenon of no pile or buckle caused by loose weaving structure or the increase of loose elasticity of the fabric due to improper softening scheme, which cannot be confused.

Thin, short and dense pile raising process

Fuzzing process is to expose the fibers on the surface of the fabric to increase the thickness of the fabric, improve its hand feel and enhance its heat preservation performance through softeners.

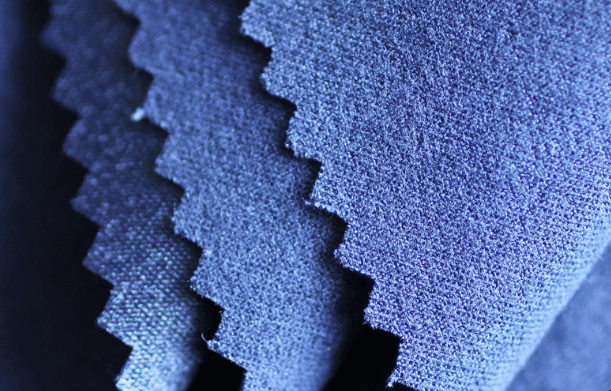

The fuzzing process directly determines the style and quality of the fabric. Through the fuzzing finishing of the fabric, the appearance and hand feel of the fabric can be significantly improved, and the warmth retention and practicality of the fabric can be improved.

In this project, by selecting the appropriate fabric structure, the tension control and shearing device are improved, and the factors such as the galling strength, galling sequence and galling times are deeply studied, and a short, dense and thin pile fabric with good application performance is developed.

Raw material selection

The fabric of this project includes base fabric layer and Terry layer, in which the base fabric layer is usually woven with ordinary polyester filament fiber cross section, and the yarn density is Wei 0.22~0.33 tex; The terry layer is woven from ultra-fine denier, fine denier or functional polyester filament, and the terry layer completely wraps the base cloth layer, showing a reverse wrapping structure. The fabric structure is compact, which increases the difficulty of carding and shearing, and overcomes the problems that light and thin fabrics are prone to hair straightening, hole defects and poor bursting when they are brushed.

Device optimization

Improve the tension control device

The tension control of the fuzzing machine is unstable, which is easy to cause the instability of fabric fuzzing quality, and serious will cause fuzzing and cloth breaking, which will affect the fuzzing of the fabric. The tension control device of the fabric feeding and the tension control device of the fabric discharging roller of the fuzzing machine are improved. Through device improvement and process optimization, a thin pile fabric has been developed, which is short and dense, has fewer holes, and has excellent hand feel and application performance.

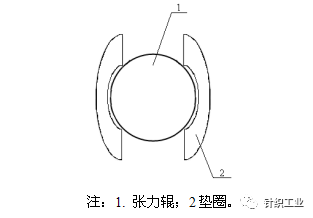

a. Feeding tension control device

The improved feeding tension control device hugs the bearing through the oil pressure control washer 2 to produce a damping tension effect. The fabric rotates on the passive tension roller 1, driving the passive tension roller 1 to operate, thereby generating tension, which is controlled by the damping force controlled by the oil pressure. In order to prevent the fabric from slipping on the passive tension roller, the passive tension roller can be wrapped with anti-skid rubber.

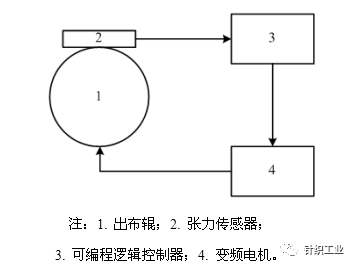

b. Tension control device of cloth delivery roller

The improved cloth outlet roller tension control device measures the fabric tension through the tension sensor installed on the cloth outlet roller, and feeds back the measured tension to the PLC at the same time. The motor speed of the cloth outlet roller can be controlled by setting the tension value on the PLC, so as to accurately control the tension of the fabric on the cloth outlet roller. Among them, PLC has the choice of speed control and tension control, which can solve the tension control mode of different elastic fabrics, so as to achieve the stable quality of fabric production.

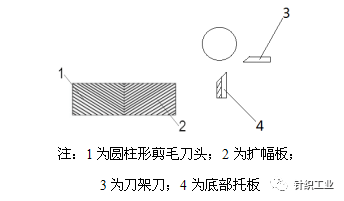

Knife head expanding device of shearing machine

Expanding device of shearing machine cutter head

The new cutter head expanding device of shearing machine has two advantages: with the help of this device, the curling of fabric can be stripped smoothly, so that the shearing effect of fabric edge is also stable, and the amount of waste cloth can be reduced; It can reduce the probability of holes in the shearing process.

Fabric development process

The process flow is: raising → combing → shearing.

Galling process

2% raising agent was selected to determine the galling sequence of “reverse side → front side → reverse side → front side → reverse side → front side” for 3 times of mild galling.

carding process

In this project, the medium reverse carding process is selected.

Shearing

The shearing knife distance is the main factor to control the shearing height. After many tests, the shearing tension, brush distance, shearing knife distance and other process parameters are optimized. Finally, the front shearing process parameters are determined as wool direction: smooth wool, shearing tension: 2.5 KGF, cloth speed tension: 1.5 KGF, knife distance: 0.8/0.15 inch, knife speed: 850 r/min, brush distance: 2.5 inch, brush speed: 50 r/min.

Sharpen, pull, scratch and brush?

- Sanding

It refers to friction on the cloth surface with sanding roller or metal roller;

Different fabrics are combined with different sand mesh numbers to achieve the desired sanding effect.

The general principle is that high count yarn uses high mesh sand skin, and low count yarn uses low mesh sand skin.

Sanding rolls are used for forward rotation and reverse rotation. Generally, an odd number of sanding rolls are used.

[factors affecting sanding effect include]

Speed, speed, moisture content of cloth, covering angle, tension, etc - Gripping

It uses a steel wire bending needle at a certain angle to insert into the yarn and hook out the fiber to form hairiness;

It has the same meaning as plucking, but it’s just a different statement;

Different fabrics use different steel needles, which can be divided into round heads and sharp heads. Generally speaking, cotton ones use sharp heads and wool ones use round heads.

[influencing factors]

Speed, speed of needle cloth roller, number of needle cloth rollers, moisture content, tension, needle cloth density, steel needle bending angle, yarn twist, additives used in pretreatment, etc. - Bristles

It uses a bristle roller like a brush to sweep the cloth surface;

Different cloth and treatment use different brush rollers, including bristle brush, steel wire brush, carbon wire brush, ceramic fiber brush.

For simple treatment, use bristle brushes, such as the brush cloth before singeing; Wire brushes are generally fabrics that need to be fluffed violently, such as knitted flannelette; Carbon wire brush is used for high-grade cotton fabric, and the surface treatment requires fine; The treatment requires more refined use of ceramic fibers.

[influencing factors]

Number of brush rollers, rotating speed, rigidity of brush wire, fineness of brush wire, density of brush wire, etc.

The difference between the three

Gripping and galling are the same concept, that is, the same process. The equipment used is a flanging machine, which uses a steel needle roller to pull out the micro fibers in the fabric yarn to form a surface fluff effect. The specific products include flannelette, silver tweed and so on. The galling process is also called “fluffing”.

The equipment used in the buffing process is a buffing machine, which uses rollers such as sandskin, carbon, ceramics, etc. to grind out the microfiber in the fabric yarn to form the fluff effect on the surface. Compared with the brushed products, the buffed fluff is short and dense, and the wool feeling is very delicate. The specific products include buffed yarn card, buffed silk, peach skin velvet, etc. Some buffed products do not look obvious, but the hand feeling is greatly improved.

Bristling is mainly a special process for corduroy, because the wool of corduroy is to cut the weft yarn of the surface tissue, disperse the yarn through the bristle and form a closed velvet strip. The equipment used is a bristling machine, which is generally equipped with 8~10 hard brushes and 6~8 crawler soft brushes. Thick corduroy also needs to be brushed after brushing. In addition to hard and soft brushes, the rear bristling machine is also equipped with wax plates, and the wool is waxed at the same time during the brushing process, which makes the corduroy strip shiny, Therefore, the back brushing machine is also called waxing machine.

Related Article

Rare earth heating fibers

Textile fabric width control

Several types of regenerated fibers that are easily confused.

Read moreSeveral types of regenerated fibers that are easily confused.

Key technologies for double-sided circular knitting machine needle plate calibration

Read moreKey technologies for double-sided circular knitting machine needle plate calibration

How a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)

Read moreHow a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)