Introduction

Jacquard Circular Knitting Machines have revolutionized the textile industry by enabling intricate and detailed pattern creation on fabrics. These machines offer a wide range of design possibilities, from complex motifs to multiple colors, allowing designers and manufacturers to unleash their creativity. With their advanced needle selection and control systems, Jacquard knitting machines produce high-quality fabrics that cater to various applications in fashion, home textiles, and technical textiles. In this blog post, we will delve into the working principle, advantages, applications, and considerations of Jacquard Circular Knitting Machines, highlighting their role in pushing the boundaries of textile design and production.

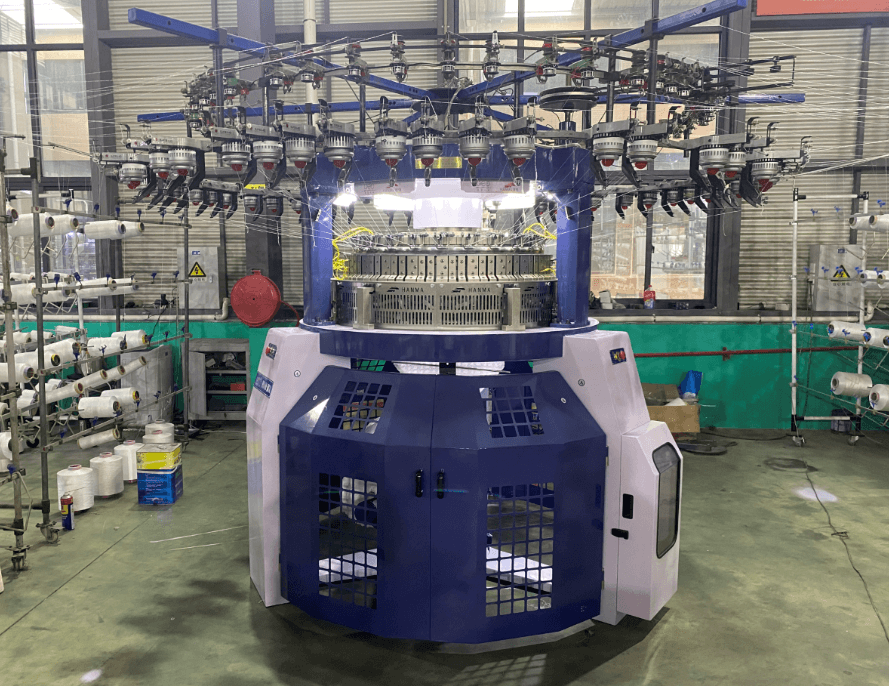

Definition of Jacquard Circular Knitting Machine

A Jacquard Circular Knitting Machine is a specialized type of circular knitting machine that is designed to create intricate patterns and designs on knitted fabrics. It utilizes a Jacquard mechanism, named after Joseph-Marie Jacquard, to control individual needles and yarns during the knitting process. The Jacquard mechanism allows for precise needle selection, enabling the creation of complex patterns, multicolored designs, and detailed motifs on the fabric. By manipulating the needles and yarns, Jacquard Circular Knitting Machines offer a high level of design flexibility and customization options, making them suitable for producing a wide range of textiles, including apparel, home textiles, and technical textiles.

Significance and applications of Jacquard knitting

Significance of Jacquard Knitting:

Jacquard knitting holds significant importance in the textile industry due to its ability to create intricate and detailed patterns on knitted fabrics. The use of the Jacquard mechanism allows for precise control over individual needles, resulting in complex designs, multicolored motifs, and varying textures. This technology offers a new level of creativity and customization, enabling designers and manufacturers to produce unique and visually captivating textiles. The significance of Jacquard knitting lies in its capability to push the boundaries of textile design, elevating the aesthetics and versatility of knitted fabrics.

Applications of Jacquard Knitting:

1. Fashion and Apparel: Jacquard knitting finds extensive application in the fashion industry for creating unique and eye-catching garments such as sweaters, dresses, skirts, and accessories. The ability to incorporate intricate patterns and multiple colors allows designers to showcase their creativity and produce high-end fashion pieces.

2. Home Textiles: Jacquard knitted fabrics are used in various home textile applications, including upholstery, curtains, draperies, beddings, and decorative textiles. The intricate patterns and textures achieved through Jacquard knitting add a touch of sophistication and elegance to interior spaces.

3. Technical Textiles: Jacquard knitting plays a crucial role in the production of technical textiles used in diverse sectors such as automotive, sports, and medical applications. These fabrics can incorporate functional elements, intricate structures, and branding details, making them suitable for applications like seat covers, sportswear, compression garments, and medical bandages.

4. Industrial and Functional Textiles: Jacquard knitting is also applied in industrial and functional textiles, including filtration fabrics, reinforcement materials, and specialty textiles. The precise control over stitch formation and pattern allows for the creation of textiles with specific properties and functionalities.

The applications of Jacquard knitting are vast and continue to expand as designers and manufacturers explore its potential. By combining aesthetics with functionality, Jacquard knitted fabrics contribute to the advancement and innovation of the textile industry.

Working Principle of Jacquard Circular Knitting Machines

A. Overview of the Knitting Process:

The knitting process in Jacquard Circular Knitting Machines follows the basic principles of circular knitting. The machine consists of a cylinder with a series of needles arranged in a circular formation. Yarn is fed into the machine, and the needles work in a synchronized manner to create knitted fabric in a continuous tube form.

B. Introduction to the Jacquard Mechanism:

The Jacquard mechanism in these machines is responsible for controlling individual needles during the knitting process. It utilizes a series of hooks, needles, and punch cards or electronic systems to determine which needles will be selected for each stitch.

C. Needle Selection and Control System:

The needle selection and control system in Jacquard Circular Knitting Machines enable the creation of intricate patterns and designs. Depending on the desired pattern, specific needles are selected and manipulated to form different types of stitches. This selection is achieved through the use of punch cards or electronic systems that control the movement of the needles.

D. Yarn Feeding and Tensioning:

Yarn feeding and tensioning are crucial aspects of the knitting process. Yarn is fed into the machine through feeders or packages, and proper tensioning ensures consistent stitch formation. The yarn is guided through various guides and tensioning devices to maintain the desired yarn tension throughout the knitting process.

By understanding the working principles of Jacquard Circular Knitting Machines, including the knitting process, Jacquard mechanism, needle selection and control system, and yarn feeding and tensioning, manufacturers can harness the full potential of these machines to create intricate and visually appealing patterns on knitted fabrics.

Key Features and Advantages of Jacquard Circular Knitting Machines

A. Intricate Pattern Creation:

Jacquard Circular Knitting Machines excel at creating intricate and detailed patterns on knitted fabrics. The precise control over individual needles allows for the formation of complex motifs, intricate textures, and varying stitch structures. This feature enables designers to bring their creative visions to life and produce fabrics with unique and captivating designs.

B. Multiple Color Capability:

One of the significant advantages of Jacquard knitting is its ability to incorporate multiple colors into the fabric. By utilizing different yarns and controlling their placement with the Jacquard mechanism, these machines can produce fabrics with intricate color patterns, gradients, and color blocks. This opens up endless possibilities for creating visually stunning and vibrant textiles.

C. Design Flexibility and Customization Options:

Jacquard Circular Knitting Machines offer exceptional design flexibility and customization options. Designers can create patterns with precise control over stitch structure, density, and yarn placement. They can experiment with various textures, geometric designs, floral motifs, logos, and more. This flexibility allows for the production of unique fabrics tailored to specific design requirements and customer preferences.

D. Enhanced Fabric Quality and Aesthetics:

The intricate patterns and precise stitch control achieved by Jacquard knitting machines result in fabrics with enhanced quality and aesthetics. The fine details and smooth transitions between colors and textures contribute to a premium look and feel of the fabric. Additionally, the controlled yarn tensioning and consistent stitch formation lead to improved fabric integrity and durability.

E. Efficient Production Process:

Despite the complex patterns and multiple color capabilities, Jacquard Circular Knitting Machines offer an efficient production process. The advanced technology and automation streamline the knitting process, increasing production speed and output. This efficiency is particularly beneficial for large-scale manufacturing, where high productivity is essential to meet market demands.

By leveraging the key features and advantages of Jacquard Circular Knitting Machines, manufacturers can produce high-quality, visually captivating fabrics with intricate patterns and multiple colors. The design flexibility, customization options, enhanced fabric quality, and efficient production process make Jacquard knitting an invaluable tool for textile designers and manufacturers seeking to push the boundaries of creativity and meet the evolving demands of the market.

Applications of Jacquard Circular Knitting Machines

A. Fashion and Apparel Industry:

1. Knitwear: Jacquard Circular Knitting Machines are widely used in the production of knitted garments, including tops, bottoms, and accessories. The intricate patterns and designs achieved through Jacquard knitting add a touch of uniqueness and sophistication to knitwear.

2. Dresses and Skirts: Jacquard fabrics are popular choices for creating elegant and eye-catching dresses and skirts. The ability to incorporate complex patterns and textures allows designers to create stunning and intricately designed garments.

3. Sweaters and Cardigans: Jacquard knitting is particularly well-suited for producing sweaters and cardigans with detailed motifs, colorwork, and textural elements. These garments showcase the craftsmanship and artistry of Jacquard fabrics.

B. Home Textiles:

1. Upholstery Fabrics: Jacquard Circular Knitting Machines are utilized in the production of upholstery fabrics for furniture. The intricate patterns and designs add visual interest and a luxurious touch to upholstery, enhancing the overall aesthetics of interior spaces.

2. Curtains and Draperies: Jacquard fabrics are commonly used in curtains and draperies, offering a wide range of design options. The ability to incorporate complex patterns and textures enables the creation of visually appealing window treatments.

3. Beddings and Blankets: Jacquard knitted fabrics are also employed in the production of beddings and blankets. The intricate designs and high-quality fabrics provide both comfort and style, transforming the bedroom into a cozy and visually pleasing environment.

C. Technical Textiles:

1. Automotive Textiles: Jacquard Circular Knitting Machines are used to produce automotive textiles such as seat covers, headliners, and interior trims. The precise control over stitch formation allows for the integration of functional and decorative elements into these textiles.

2. Sports Textiles: Jacquard fabrics find applications in sports textiles, including activewear, compression garments, and sports accessories. The ability to create patterns, ventilation zones, and branding details enhances both the performance and aesthetics of sports apparel.

3. Medical Textiles: Jacquard knitting technology is utilized in the production of medical textiles, including bandages, compression stockings, and orthopedic garments. The intricate patterns and controlled fabric properties contribute to the functionality and effectiveness of these medical textiles.

Jacquard Circular Knitting Machines find versatile applications across various industries, including fashion and apparel, home textiles, and technical textiles. The ability to create intricate patterns, incorporate multiple colors, and achieve design flexibility makes Jacquard fabrics highly desirable for a range of products, adding a touch of elegance and sophistication to the end result.

Conclusion

A. Recap of the Importance and Versatility of Jacquard Circular Knitting Machines:

Jacquard Circular Knitting Machines play a crucial role in the textile industry, offering unparalleled capabilities in creating intricate patterns, multiple colors, and design flexibility. These machines enable the production of high-quality fabrics with enhanced aesthetics, making them essential tools for designers and manufacturers across various sectors.

B. Potential for Innovation and Creativity in Textile Design and Production:

The use of Jacquard Circular Knitting Machines opens up a world of possibilities for innovation and creativity in textile design and production. Designers can explore intricate motifs, complex patterns, and unique color combinations, pushing the boundaries of what is possible in fabric creation. This technology allows for the development of truly one-of-a-kind textiles that stand out in the market.

C. Encouragement to Explore the Possibilities Offered by Jacquard Knitting Technology:

In conclusion, the potential of Jacquard knitting technology is vast and exciting. It empowers designers and manufacturers to unleash their creativity, create visually stunning fabrics, and meet the diverse demands of different industries. By embracing Jacquard Circular Knitting Machines, the textile industry can continue to thrive with innovative designs, exceptional quality, and endless possibilities.

As we move forward, let us embrace the importance and versatility of Jacquard Circular Knitting Machines, harness the potential for innovation and creativity, and explore the endless possibilities offered by this remarkable technology. Together, we can shape the future of textile design and production and bring forth a new era of captivating and unique fabrics.

Related Article

Rare earth heating fibers

Textile fabric width control

Several types of regenerated fibers that are easily confused.

Read moreSeveral types of regenerated fibers that are easily confused.

Key technologies for double-sided circular knitting machine needle plate calibration

Read moreKey technologies for double-sided circular knitting machine needle plate calibration

How a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)

Read moreHow a Circular Knitting Machine Releases and Lowers the Fabric (Shake-down Process)