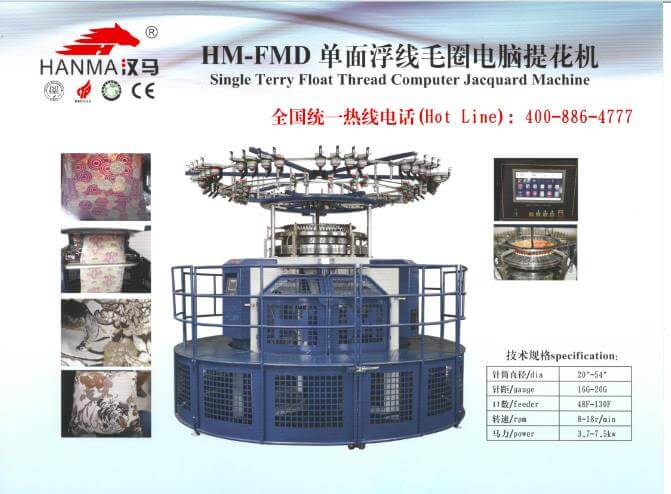

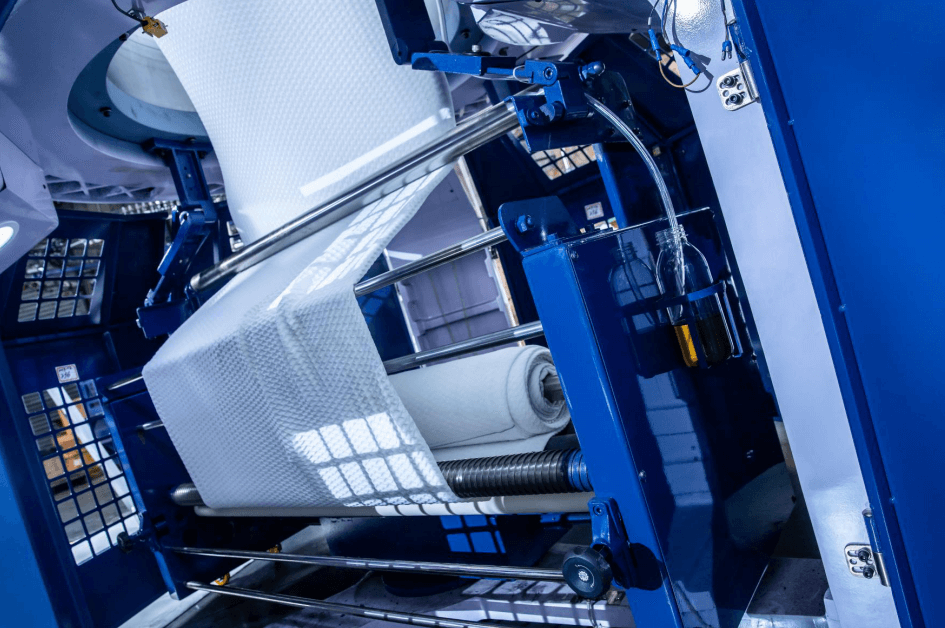

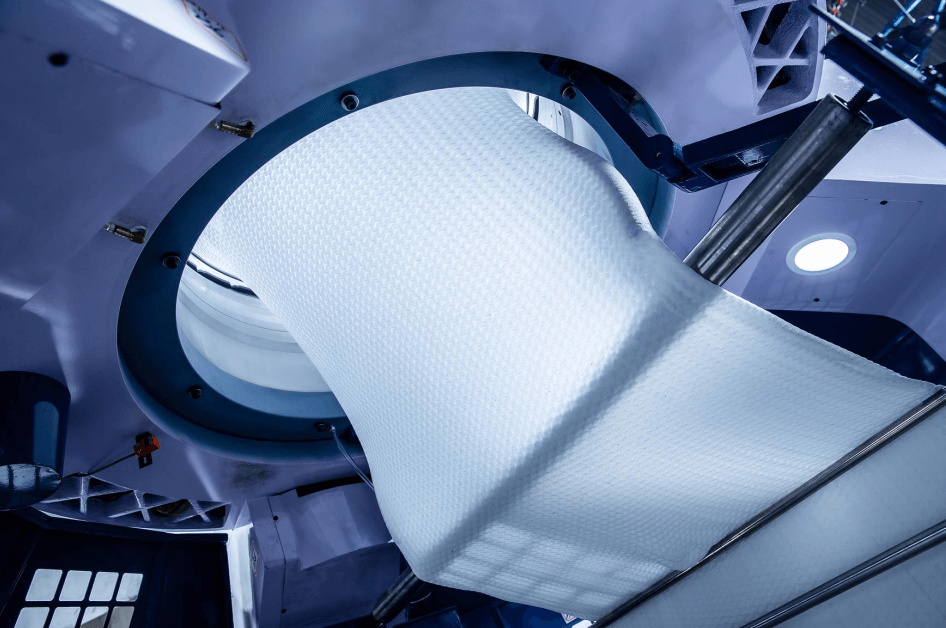

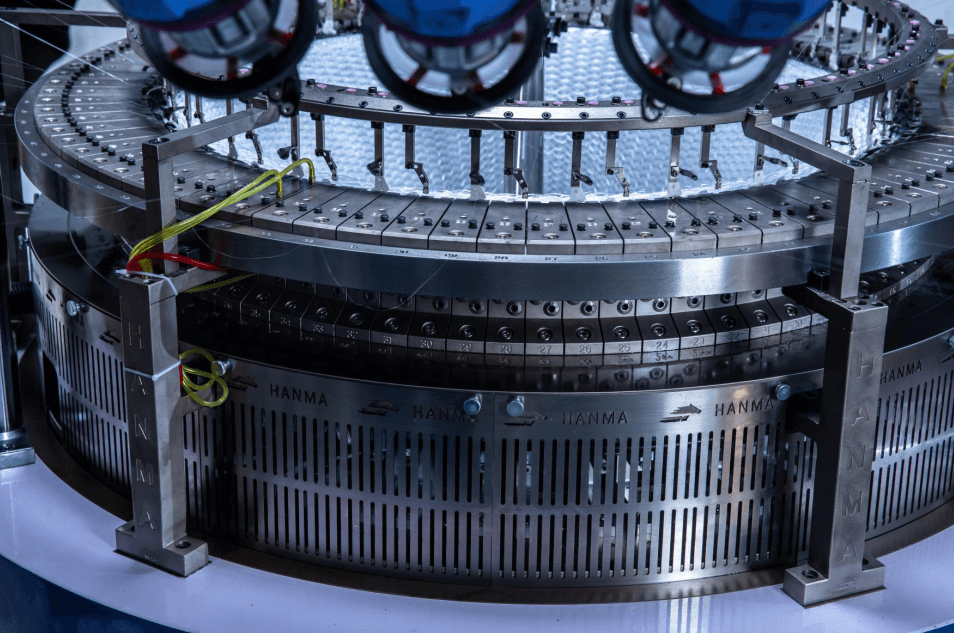

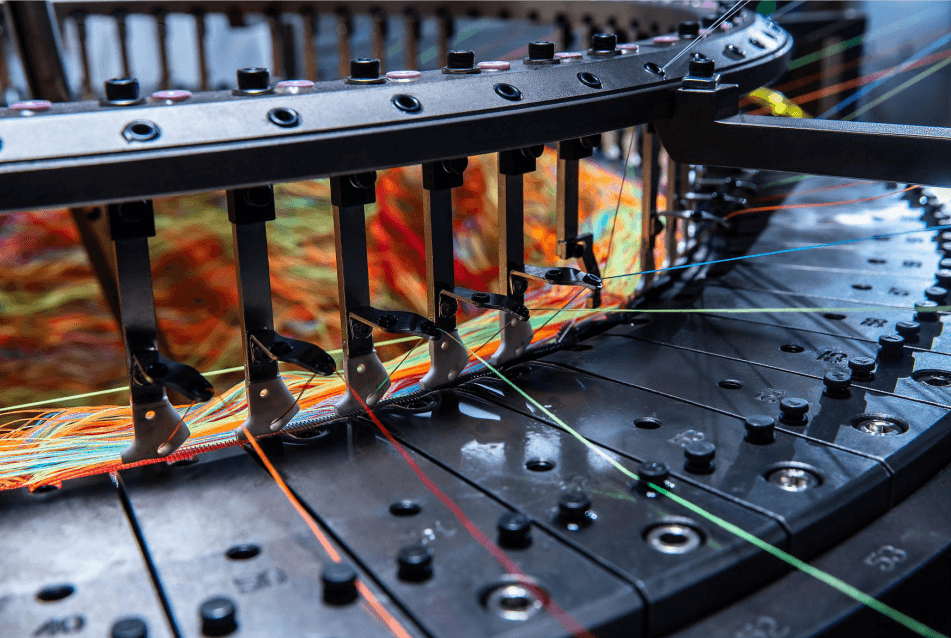

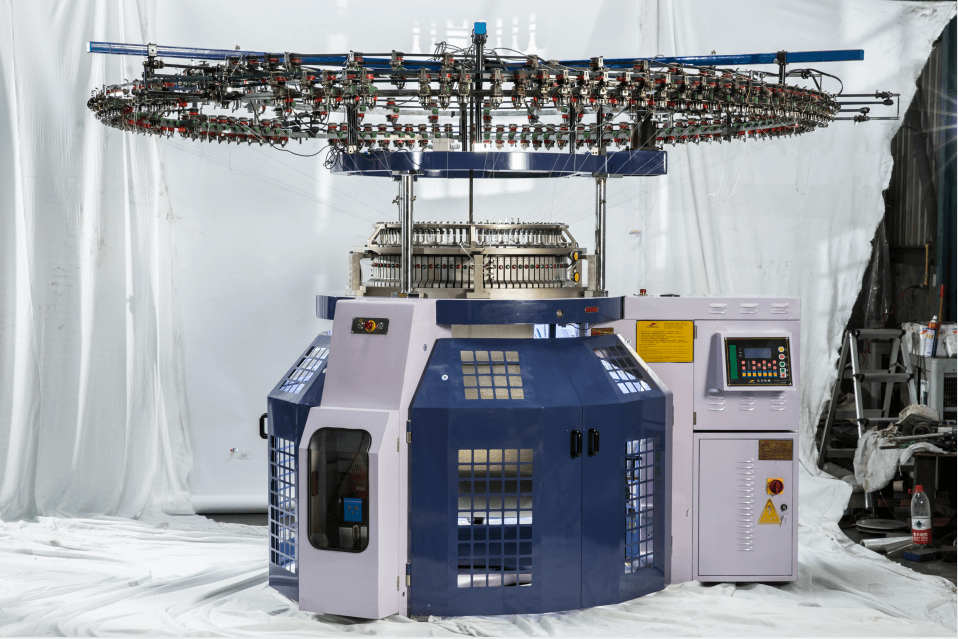

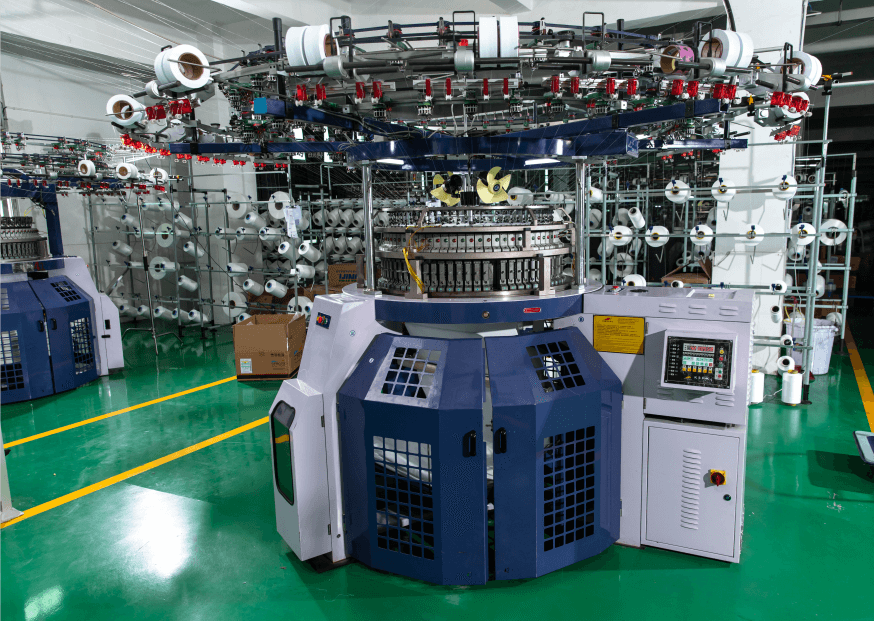

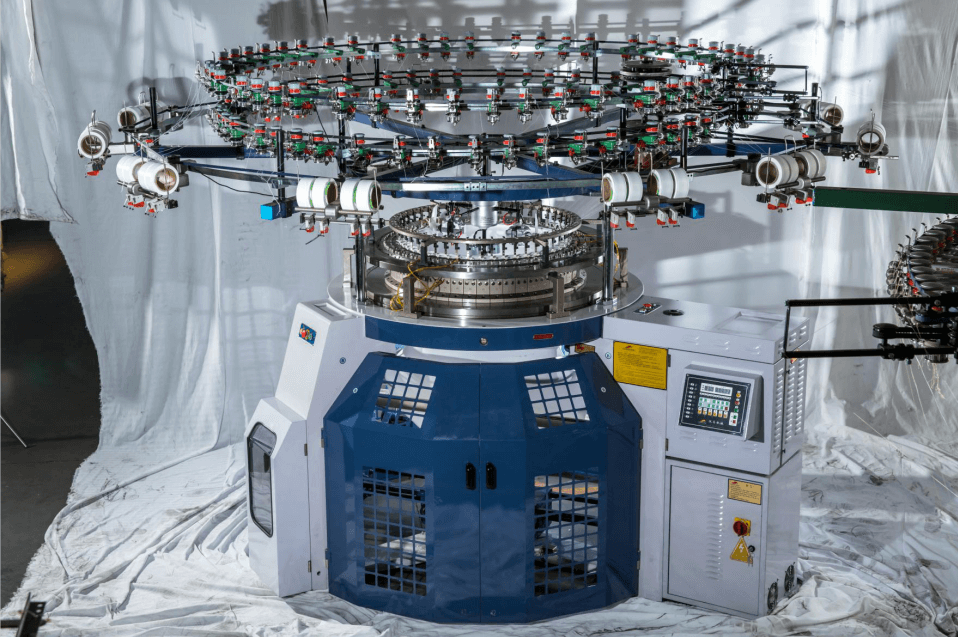

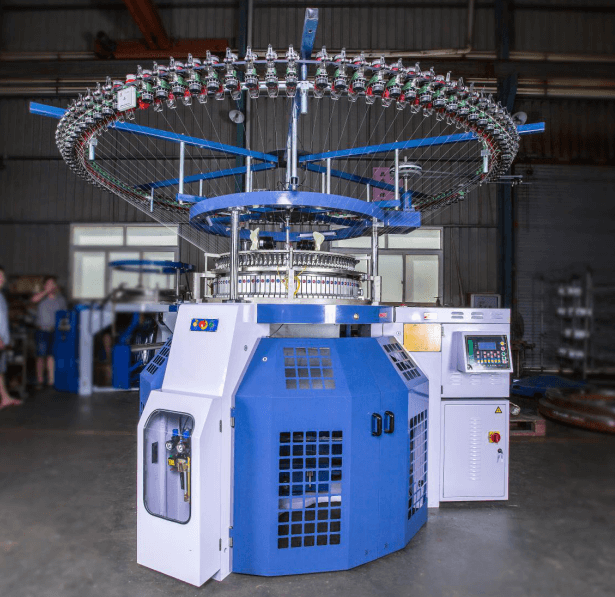

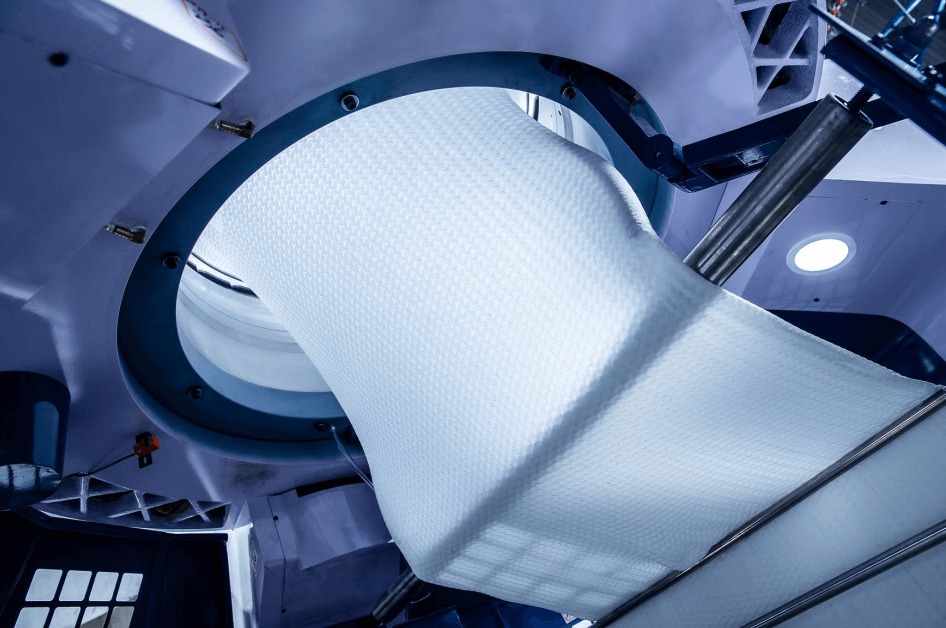

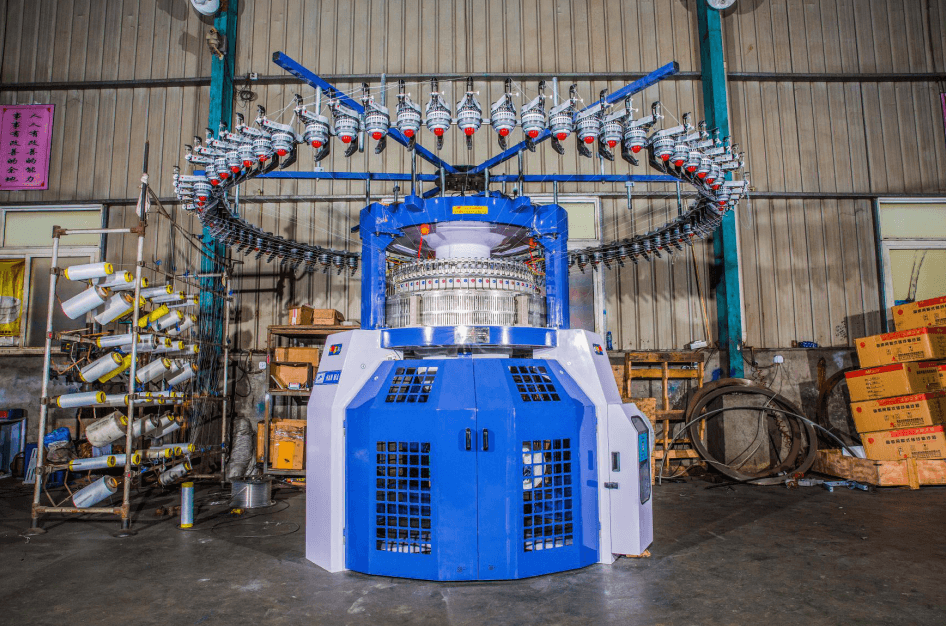

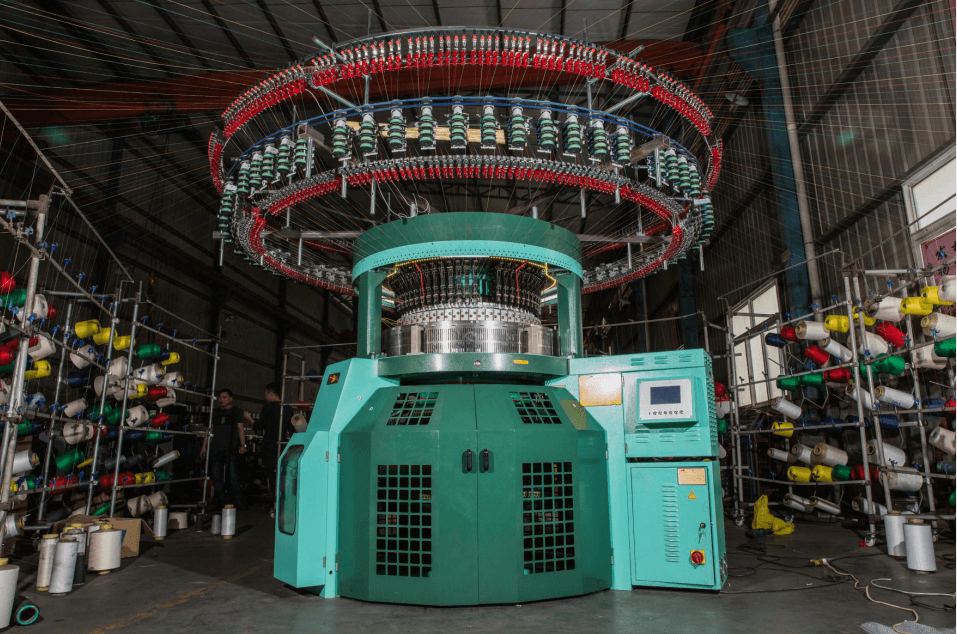

“Hanma “ Brand Single Terry Float Thread Computer Jacquard Machine, Specializing Multicolor High-grade Sofa Cover Fabric, Curtain Fabric, Auto Pillow Etc., Can up To 6 Colors, The Machine is made by advanced processing Equipment And imported Materials, With Fast speed, High Output,

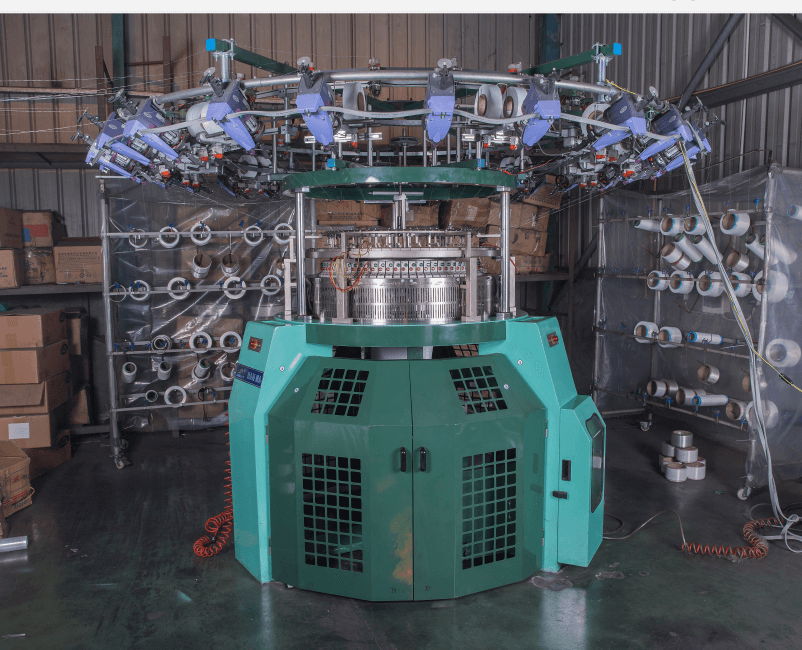

A revolutionary design is born from the single jersey four tracks model series, Hanma’s latest float plating knitting machines. Based from the patented technology in striper jacquard successful in the upholstery industries, the advantages of simple four tracks structure with the “ float plating” performance can reach the woven like marked request.

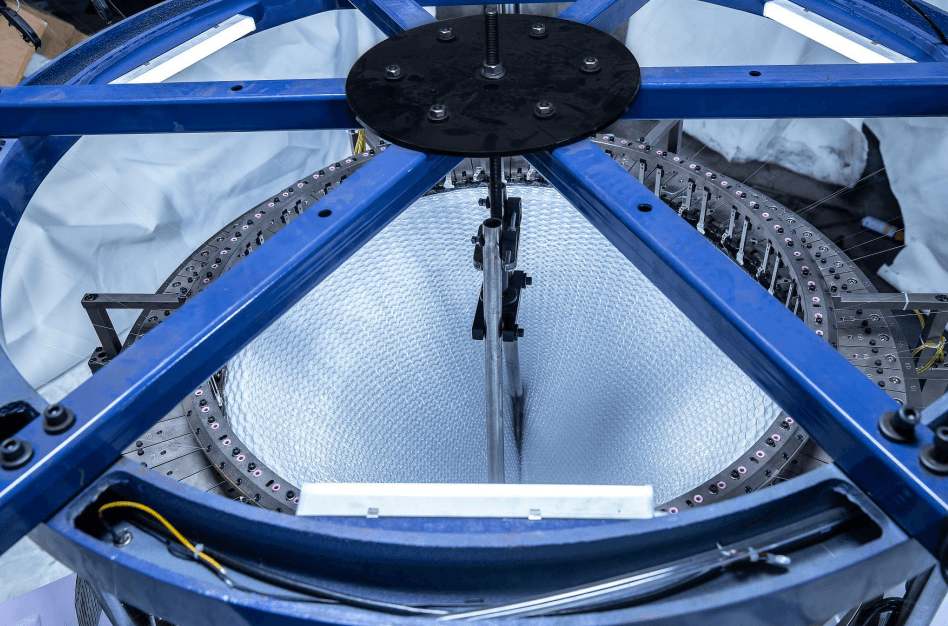

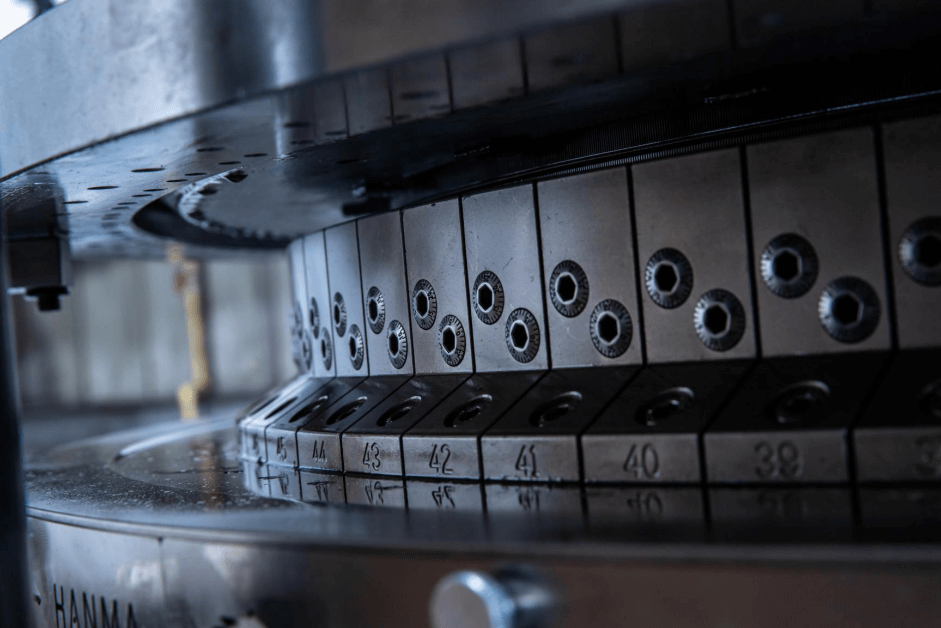

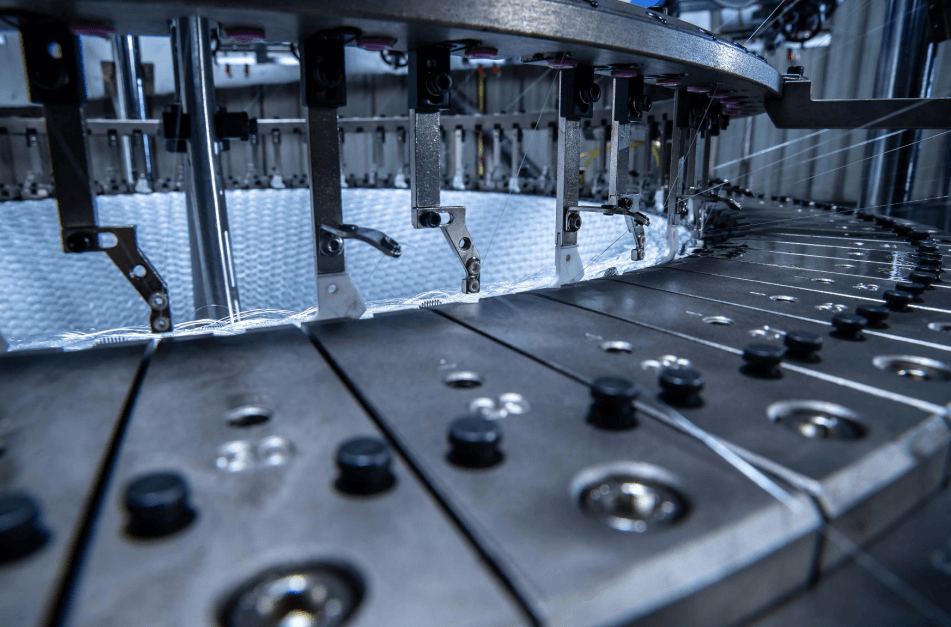

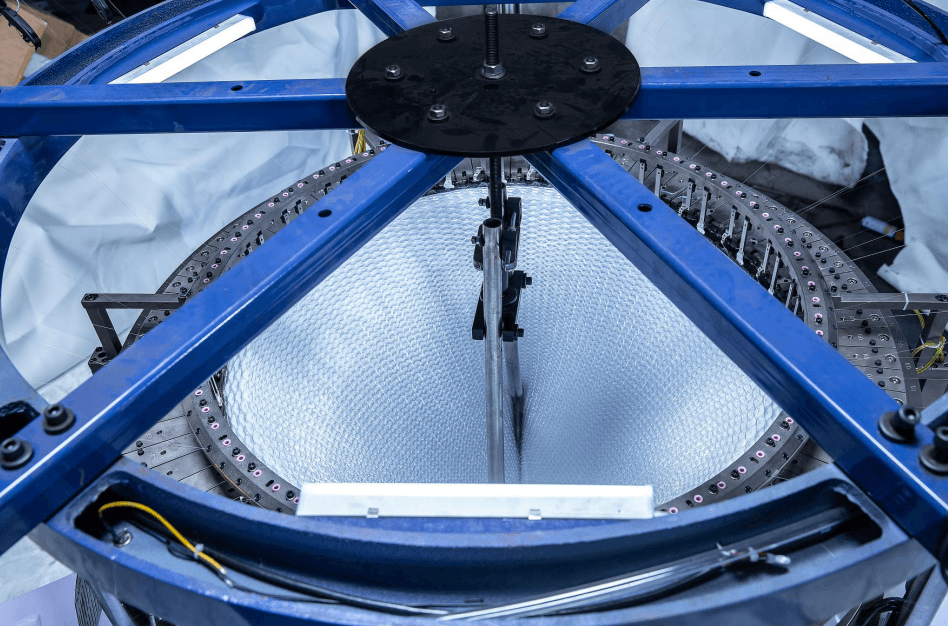

Even so, every feat of the PL-KSFP(B) is very much a product of Hanma’s float plating technology. New resources and new investment in the latest computer aided design and engineering facilities, with statistical process control and many other leading edge disciplines are ensuring for perfect knitting processing with basic four cams track system only. With certain yarns arranged, woven-like fabrics including knitted denim can be better than ever before. The cam system has the potential to be converted easily for other single jersey structure.

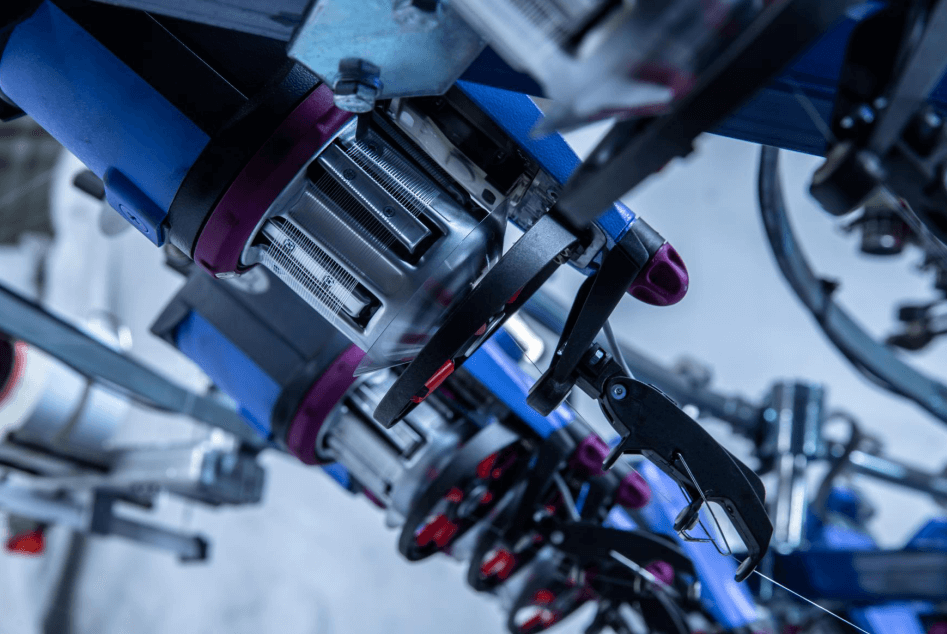

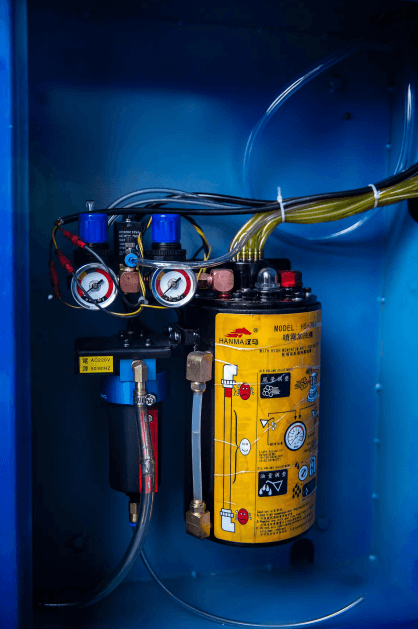

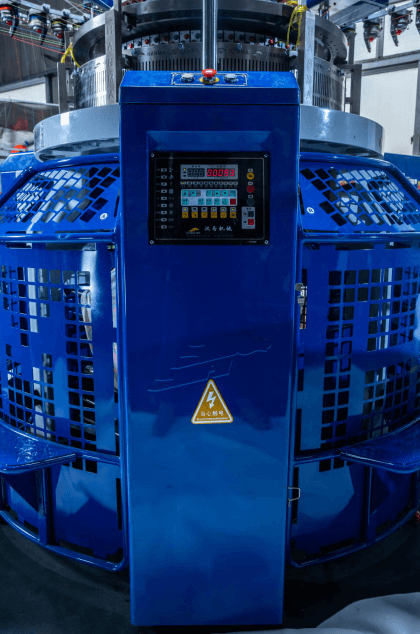

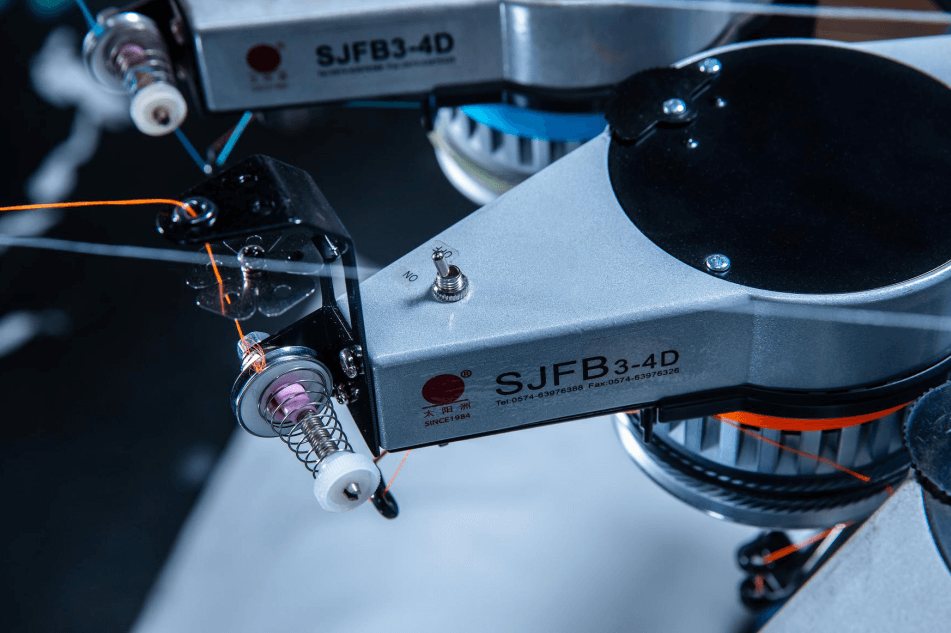

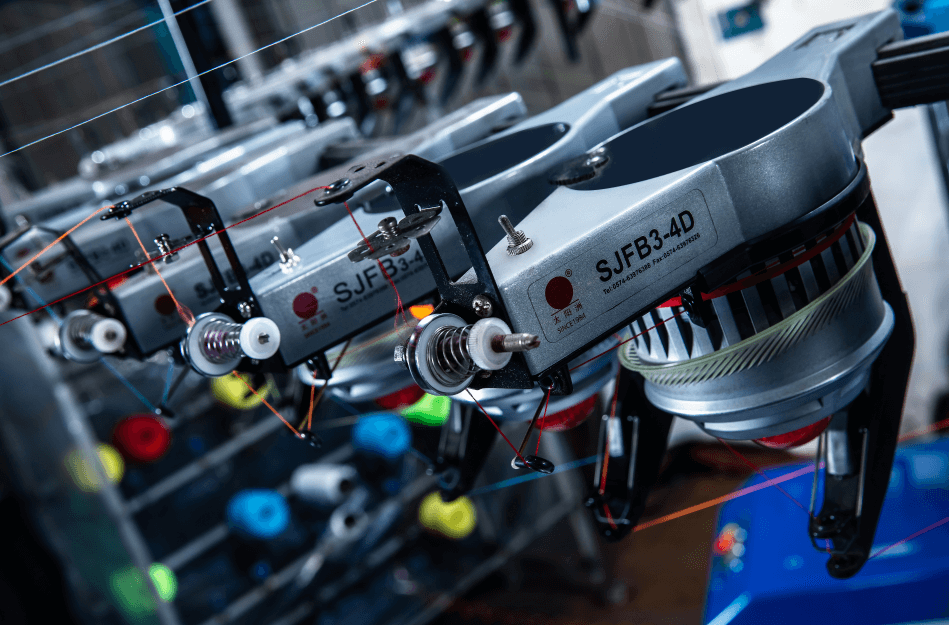

The PL-KSFP(B) is equipped with Hanma’s Knitel technology and the sophisticated yarn feeding design with the carrier system. The quality wheel gearbox is oil bathed for high quality fabric production even in sudden braking. High quality can surface for improving sinker and needle lifetime. Powerful interior anti-dust fan and blower for knitting head area cleaning. Digital option devices supply for full factory management & quality control.

Diameter 20’-54’

Gauge: 16G-20G

Feeder: 48F-130F

RPM: 8-18r/min

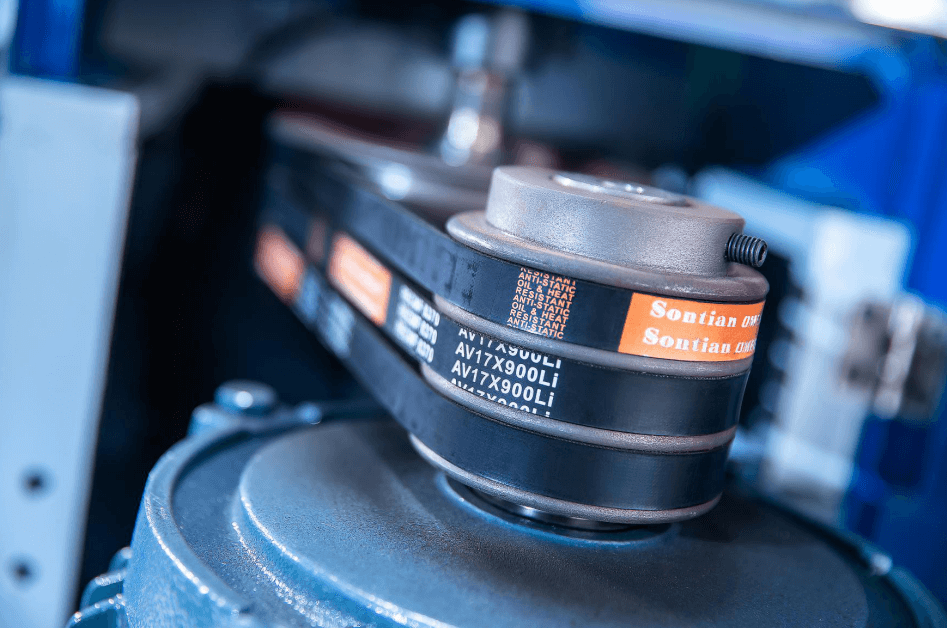

Power:3.7-7.5kw

related product

High speed three thread fleece circular knitting machine

SINGLE TERRY FLOAT THREAD COMPUTER JACQUARD Circular knitting MACHINE

SINGLE JERSEY JACQUARD circular KNITTING MACHINE(UTOPIAN)

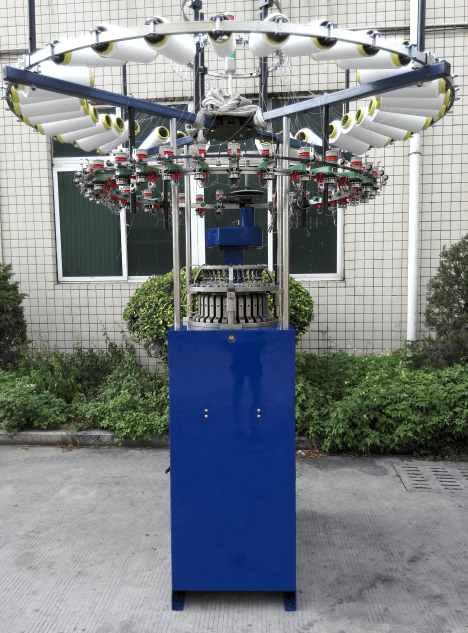

SMALL SIZE SINGLE JERSEY CIRCULAR KNITTING MACHINE

SINGLE JERSEY OPEN WIDTH circular KNITTING MACHINE

SINGLE TERRY CIRCULAR KNITTING MAchiNE

SINGLE JERSEY KNITTING MACHINE

Contract us

| No | Description | Supplier | Brand | Quantity |

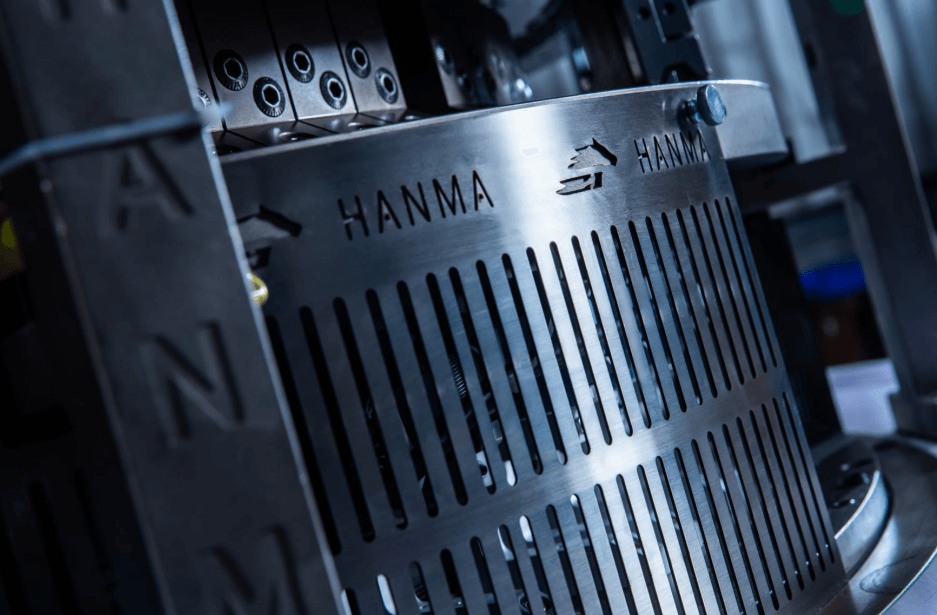

| 1 | Insert flake type cylinde&dlar (Germany metal) | Hanma | China | 1 unit |

| 2 | Needles | Groz-beckert | Germany | 1 set |

| 3 | Sinkers | Groz-beckert | Germany | 1 set |

| 4 | Electric Positive storage yarn feeders | Sun | China | 1 unit |

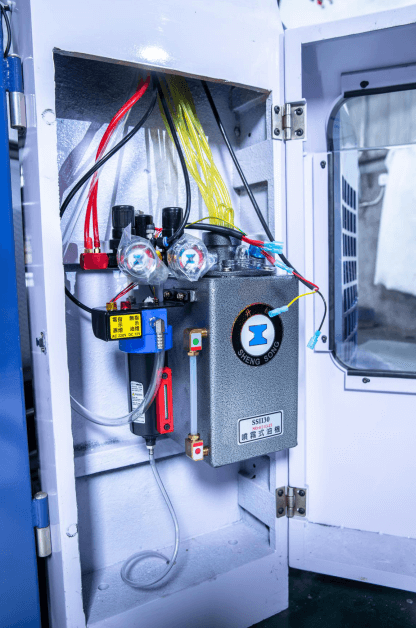

| 5 | Oiling lubricator | Hongsheng | China | 1 unit |

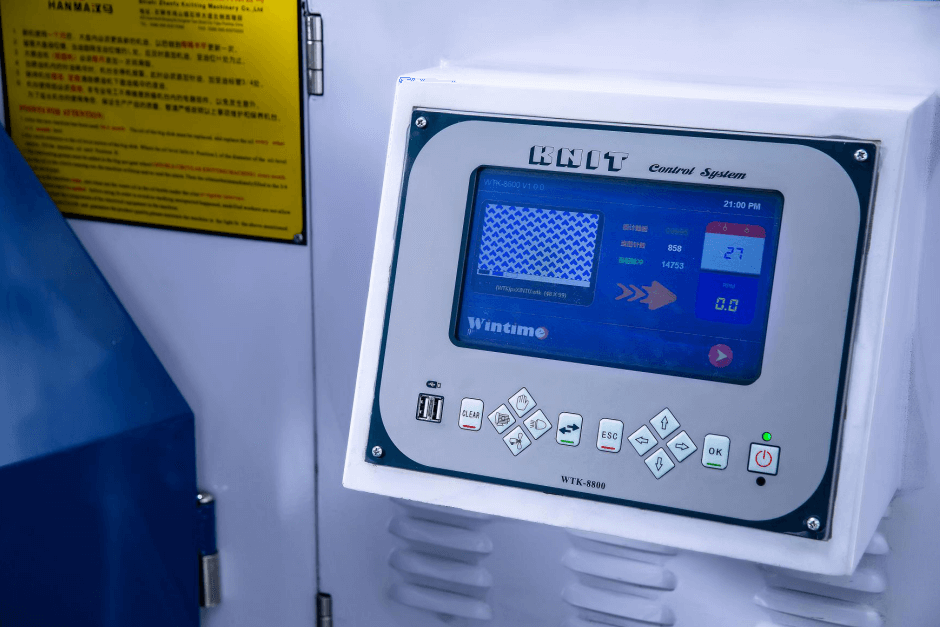

| 6 | Computer system (3ways) | Chuangda Model | China | 1 unit |

| 7 | Needle selector system | Chuangda Model | China | 1 unit |

| 8 | Yarn creel Tube Aluminium | Hanma | China | 1 set |

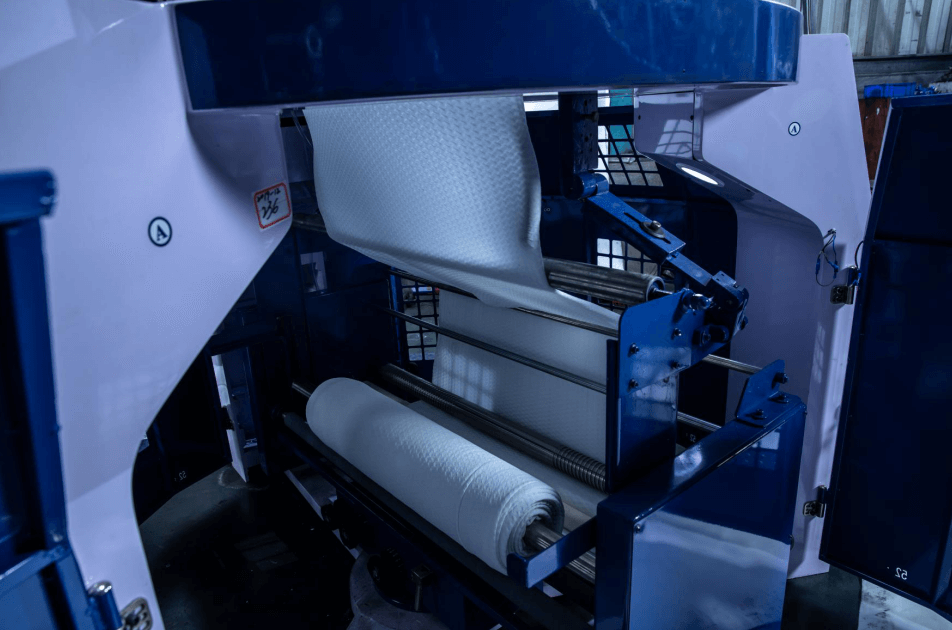

| 9 | One ways Take-down device | Yongtai | Taiwan | 1 set |

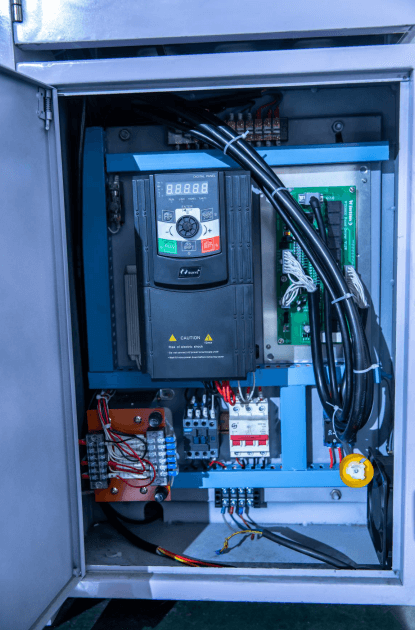

| 10 | Invertor for motor controller | Sunyue | Taiwan | 1 set |

| 11 | fabric Spreader equipment | Hanma | China | 1 set |

| 12 | Sinker cams | Japan | China | 1 set |

| 13 | Knit Cams | Japan | China | 1 set |

| 14 | Automatic dust fans with blower equipment. | San song | China | 1 set |

| 15 | Radar type round 360”Clear dust equipment | San song | China | 1 set |

| 16 | Control panel LCD Screen | Hanma | Taiwan | 1 set |

| 17 | Spare tools | 1 set | ||

| 18 | Operation manual for invertor & controller panel | 1 set | ||

| 19 | Extra Spare parts : (a) 100pcs needles (b)100pcs sinkers (c)Feeders 2pcs (d)Air blower gun 1 set (e)Fuse 4pcs (f) Yarn carrier 1pcs (g)Needle oil 1 liter(h) extra needle selector 1 pc |

| Condition: New | Product Type:fabric | Type:Circular | Production Capacity:250-750kg |

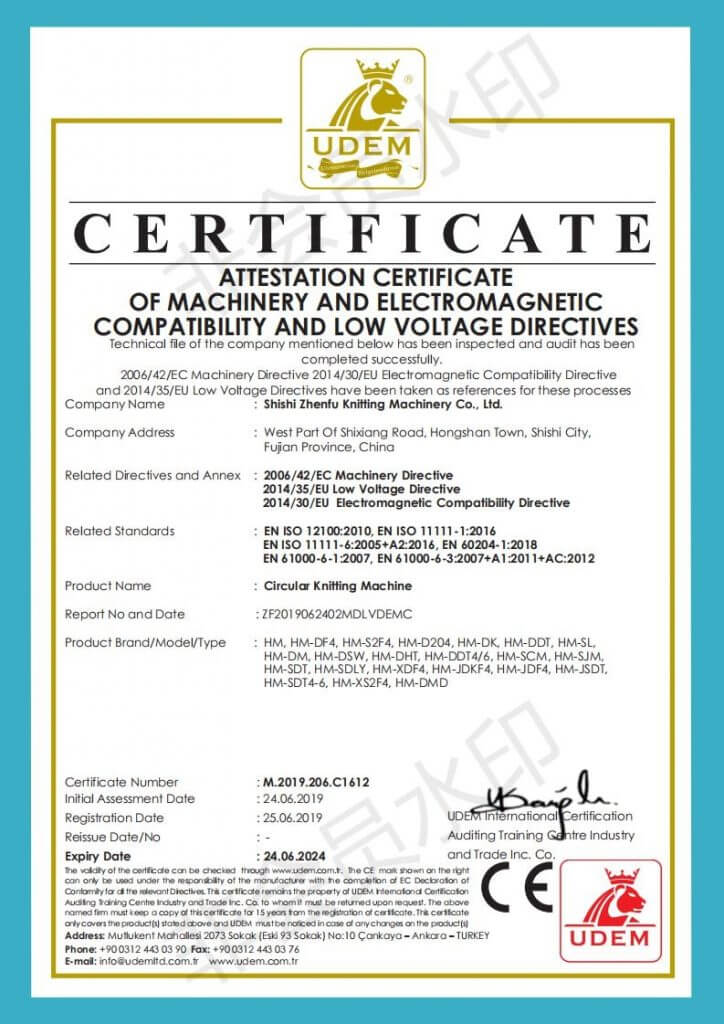

| Place of Origin: Fujian China (Mainland) | Brand Name:HANMA (circular knitting machine) | Model Number:HM-DF4 (circular knitting machine) | Power(W):5.5kw (circular knitting machine) |

| Knitting Style: knitted | Knitting Method: Single | Computerized: Yes | Weight:2.5TON |

| Dimension(L*W*H):2.35*2.28*2.28M | After-sales Service Provided:Engineers available to service machinery overseas | speed:0-30RPM | Certificate: CE |

| machine type: single terry jacquard | turn way: anticlockwise | fabric function:sports garment |

Related RFQ

Company Profile

Zhenfu Knitting Machinery Co., Ltd. is a professional enterprise specializing in manufacturing machines, woven products, and apparel. We are also engaged in the production and design of fabrics and large diameter circular knitting machines for woof weaving and knitting. We have three trademarks — “HANMA”, “LUHU”, “ZHENFU”.We introduced foreign advanced computer process equipment and test and measurement instruments. We also research information reflection from consumers for stratifying customers’ different demands. We have a group of engineer technicians with rich experience. They can develop new products according to customers’ specifications. We are based on the enterprise tenet of “Credit, Factualism, and Innovation” and persist in the management concept of “Quality is the Base and Credit is the First”. We can supply top-ranking products and perfect after-sales services to our customers. We have taken root in a vehemently competing market of diameter circular knitting machines. Our company was awarded ISO9001 certificate in 2003. We have developed into a production factory with a certain scale. We offer large diameter circular knitting machines, including rib universal machines, large high-speed and single-sided jacquard cylinders, high-speed and single-sided large diameter circular knitting machines, back-to-face packed pole loop machines, and single-sided sanitary clothes. We welcome all clients to contact us.

Related product

Computerized Single Jersey Auto-Striper circular Knitting Machine

Computerized Single Jacquard Circular Knitting Machine

Computer Jacquard circular knitting machine

DOUBLE JERSEY JACQUARD CIRCULAR KNITTING MACHINE

DOUBLE JERSEY AUTO-STRIPER CIRCULAR KNITTING MACHINE (FOUR/SIX COLORS)

DOUBLE RIB JACQUARD CIRCULAR KNITTING MACHINE

Related Article

Circular knitting machine basic operation knowledge

Read moreCircular knitting machine basic operation knowledge

circular knitting machine price

what is the structure of large circular knitting machines

Read morewhat is the structure of large circular knitting machines