How to distinguish pure cotton from polyester cotton?

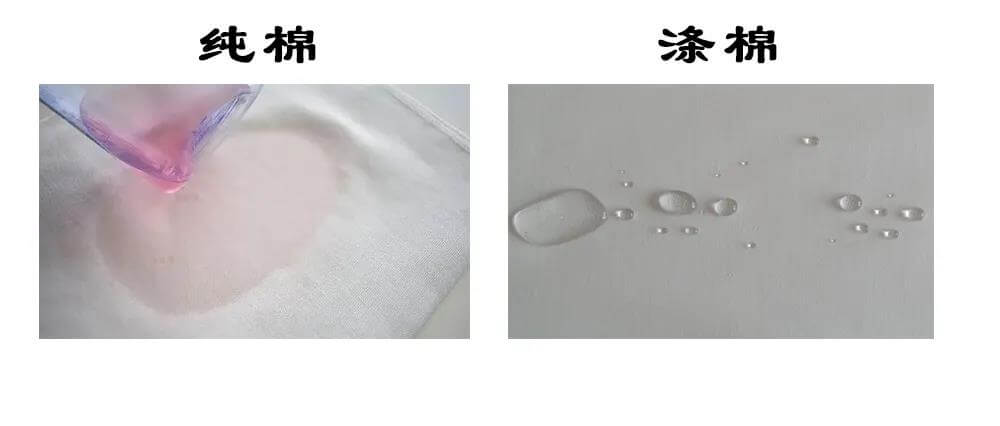

Cotton is fiber and hair is keratin. It’s totally different. Cotton won’t burn the smell of hair. Pure cotton feels soft, but the twist is astringent, easy to dye, but the color boundary is not as clear as polyester cotton. Find a thread and burn it, it will burn into a fine ash, and there will be no caking on the thread. Pure cotton has good water absorption. Polyester cotton is the opposite.

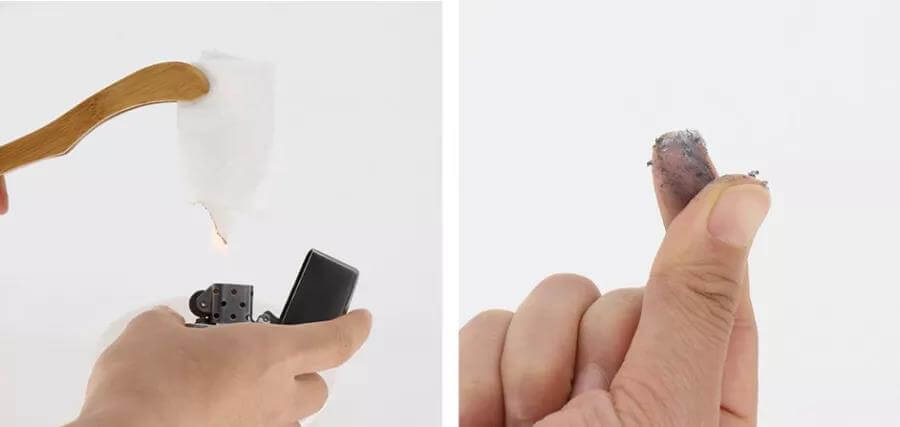

Find a thread from the clothes and light it. If there is a burning smell, that is, the smell of burning hair, it is pure cotton. You can try it. Pure cotton feels more textured and polyester feels smoother. In addition, pure cotton doesn’t pilling and polyester pilling. When put in water, pure cotton can easily absorb water, but polyester won’t.

Take some yarn from the cloth, light it and blow it out. Rub the burned residue with your fingers. It feels that polyester-cotton has hard particles; Without hard particles, all ash is pure cotton.

Pure cotton is made of natural cotton fiber. Generally, there is a label [cotton] / cotton / C. Pinch it with your hand. If it’s wrinkled. It’s pure cotton. After burning pure cotton, it’s noodles. Otherwise, it’s a hard black thing with oil droplets (blocks). Put it in your mouth and bite it. If it creaks, it’s not pure cotton. If there’s no sound, it’s pure cotton.

Characteristics of pure cotton fabrics

① Hygroscopicity: cotton fiber has good hygroscopicity. Under normal circumstances, the fiber can absorb water into the surrounding atmosphere, with a moisture content of 8-10%, so it contacts people’s skin and makes people feel soft but not stiff. If the humidity of cotton cloth increases and the surrounding temperature is high, all the water content in the fiber will evaporate and disperse, so as to keep the fabric in water balance and make people feel comfortable.

② Moisture retention: because cotton fiber is a bad conductor of heat and electricity, the thermal conductivity is very low, and because cotton fiber itself has the advantages of porosity and high elasticity, a large amount of air can be accumulated between fibers, and the air is a bad conductor of heat and electricity, pure cotton fiber textiles have good moisture retention, and people feel warm wearing pure cotton fabrics and clothes.

③ Heat resistance: pure cotton fabric has good heat resistance. When the temperature is below 110 ℃, it will only cause water evaporation on the fabric and will not damage the fiber. Therefore, the wearing, washing, printing, and dyeing of pure cotton fabric at room temperature have no impact on the fabric, which improves the washing, wearing, and wearing performance of the pure cotton fabric.

④ Alkali resistance: cotton fiber has great resistance to alkali. When cotton fiber is in an alkali solution, the fiber will not be damaged. This performance is conducive to washing, disinfection, and impurity removal after taking. At the same time, it can also dye, print, and process pure cotton textiles, so as to produce more new cotton varieties.

⑤ Hygiene: cotton fiber is a natural fiber. Its main component is cellulose, as well as a small number of waxy substances, nitrogen-containing substances, and pectin. Pure cotton fabric has been inspected and practiced in many aspects. The contact between the fabric and the skin has no stimulation and negative effect. It is beneficial and harmless to the human body for a long time and has good hygienic performance.

All cotton is pure cotton. 100% cotton fabric. It feels soft and comfortable. Polyester cotton is a mixture of polyester and cotton. It feels less comfortable than cotton. It’s not as good as cotton. A variety of fabrics are made of polyester staple fiber and cotton fiber blended yarn, commonly known as cotton Dacron.

Polyester is the largest variety with the highest yield in synthetic fiber. Polyester has many trade names, “polyester” is the trade name of our country. The chemical name is polyethylene terephthalate, which is usually polymerized by chemicals, so the scientific name often carries “poly”. Polyester is also called polyester. Structure and performance: the structure shape is determined by the spinneret hole. The cross-section of conventional polyester is circular without a middle cavity. By changing the cross-sectional shape of the fiber, special-shaped fiber can be made. Improve brightness and cohesion. Fiber macromolecules have high crystallinity and orientation, so the fiber has high strength (20 times that of viscose fiber) and good friction resistance. It is not easy to wrinkle, crisp, good shape retention, good light resistance, and heat resistance. It can be dried and ironed quickly after washing and has good wearability after washing. Polyester is a chemical fiber fabric, which is not easy to sweat. It feels pricked and pulled. It is easy to generate static electricity. It looks bright obliquely.

one

Visual identification method:

A. All cotton: there are many fluffs and poor surface finish

B. Polyester cotton: relatively little fluff, good surface finish, and certain luster.

two

Combustion method:

A. All cotton: near flame, burning paper, less ash, soft black ash.

B. Polyester cotton: near flame shrinkage, dripping, foaming, weak fragrance, hard light brown

Cotton has the advantages of absorbing sweat, breathable, soft, warm, and sensitive, but its disadvantages are easy to shrink and deform! Now it is very good to add some polyester to cotton clothes, and now pure clothes are so cheap. Clothes with polyester or spandex are more expensive. Adding polyester will make up for the shortcomings of cotton.

What are the skills to distinguish brocade cotton from polyester cotton?

Brocade cotton is more wear-resistant than polyester cotton. Under the same proportion of ingredients, the former feels generally stiff.

Brocade cotton: it is interwoven with nylon silk and pure cotton yarn on an air-jet loom. It is an ideal material for making casual clothes and fashion. Specifications include plain, twill, extinction, square root, and other series. The cloth has a bright luster and a smooth and full feel. It is mostly suitable for windbreakers, cotton jackets, jackets,s, and other styles.

Refined cotton: refers to combed cotton

Polyester: it is an important variety of synthetic fiber and the trade name of polyester fiber in China. It is a fiber made from purified terephthalic acid (PTA) or dimethyl terephthalate (DMT) and ethylene glycol (eg) through esterification or transesterification and polycondensation, polyethylene terephthalate (PET), spinning, and post-treatment.

Polyester cotton: it refers to the general name of polyester and cotton blended fabric, commonly known as dacron of cotton.

Chemical fiber: chemical fiber fabric is a new type of clothing material developed in modern times. Here mainly refers to pure spinning, blending or interwoven fabrics processed from chemical fibers, that is, fabrics woven from purified fibers, excluding blends and interwoven fabrics with natural fibers. The characteristics of chemical fiber fabrics are determined by the characteristics of the chemical fibers themselves.

CVC = chief value of cotton is mainly composed of cotton, that is, cotton accounts for more than 50%. The more cotton components, the more expensive the price.

T / R polyester viscose: T / R fabric is polyester viscose blended fabric. Polyester viscose blend is a kind of blend with strong complementarity. Polyester viscose has not only cotton type, wool type, but also medium-length type. Wool fabric is commonly known as “Kuaiba”. When the polyester is not less than 50%, the blended fabric can maintain the characteristics of firmness, wrinkle resistance, dimensional stability, and strong washability and wearability of polyester. The mixing of viscose fiber improves the air permeability and melt hole resistance of the fabric; The pilling and the anti-static phenomenon of the fabric are reduced.

Polyester / Viscose Blend: multi-purpose 65 / 35 or 67 / 33. Polyester / rich blend is the same as polyester/viscose. This kind of blended fabric is characterized by smooth, bright color, strong wool feeling, good hand elasticity, and good moisture absorption; But the non-ironing property is poor.

Nylon/nylon: it is the Chinese name of synthetic fiber nylon, also known as “nylon” and “nylon”, and its scientific name is polyamide fiber, that is, polyamide fiber. Because Jinzhou Chemical Fiber Factory is the first factory in China to synthesize polyamide fiber, it is named “nylon”. It is the earliest variety of synthetic fiber in the world. It has been widely used because of its excellent performance and rich raw material resources.

How to identify?

● pure cotton has a good hand feel, comfortable use, easy dyeing, a rich variety of patterns, soft and warm, strong moisture absorption, washing resistance, and less static electricity, but it is easy to wrinkle, easy to shrink, has poor elasticity, acid and alkali resistance, and should not be treated for a long time at a high temperature of more than 100 ℃, so it is best to spray wet when ironing cotton products, which is easy to iron. If possible, use a steam iron to iron the product after each use, and the effect will be better.

● yarn-dyed pure cotton is a kind of pure cotton fabric, which is woven with warp and weft yarns of different colors. Due to dyeing before weaving, the dye permeability is strong, the color fastness is good, and the three-dimensional feeling of different color yarn fabric is strong and the style is unique. It has the characteristics of pure cotton fabric, but usually, the shrinkage is greater.

● the warp and weft density of high count and High-Density Jacquard pure cotton fabric is particularly large, and the weaving method is rich. Therefore, the fabric has a thick feel, good durability, and a high surface finish. It is a mostly light color, with natural color flowers at the bottom, which is particularly chic and elegant. It is a more advanced kind of pure cotton fabric.

● polyester cotton brand products generally adopt polyester-cotton fabrics with a ratio of 65% polyester and 35% cotton. Polyester cotton is divided into plain and twill. Plain polyester-cotton cloth has a thin surface, good strength and wear resistance, and small shrinkage. The appearance of the product is not easy to be out of shape, and the price is affordable and durable, but the comfort and intimacy are not as good as pure cotton. In addition, because polyester is not easy to dye, polyester cotton fabrics are mostly light and light tone, which is more suitable for spring and summer. Twill polyester cotton is usually more dense than plain, so it appears dense and thick, and its surface luster and feel are better than plain.

Can you tell the difference between polyester cotton, all cotton, and all polyester cloth with the naked eye or touch?

Burn, watch the fire. The flame of cotton is soft and finally burned into ash. The polyester will jump and emit black smoke and burn into hard caking. Polyester cotton is the combination of the two. Generally, you can also see the small jump of flame. In most cases, it is soft, much like pure cotton, but in the end, it produces hard blocks, which are smaller than pure polyester.

Polyester – cotton is a kind of yarn made of polyester staple and cotton

The combustion method can be used to distinguish. When polyester meets heat, it will melt into black beads, accompanied by black smoke, while the cotton will burn into ash. When polyester and cotton products burn, they will feel like polyester. However, due to the slightly high ignition point of cotton (400 degrees), the red ash of cotton can be seen at the end of combustion.

Related Article

What is knowledge of yarn-dyed

what is Textile technology knowledge

What is heat-setting knowledge?

circular knitting machine guide

what is the structure of large circular knitting machines

Read morewhat is the structure of large circular knitting machines