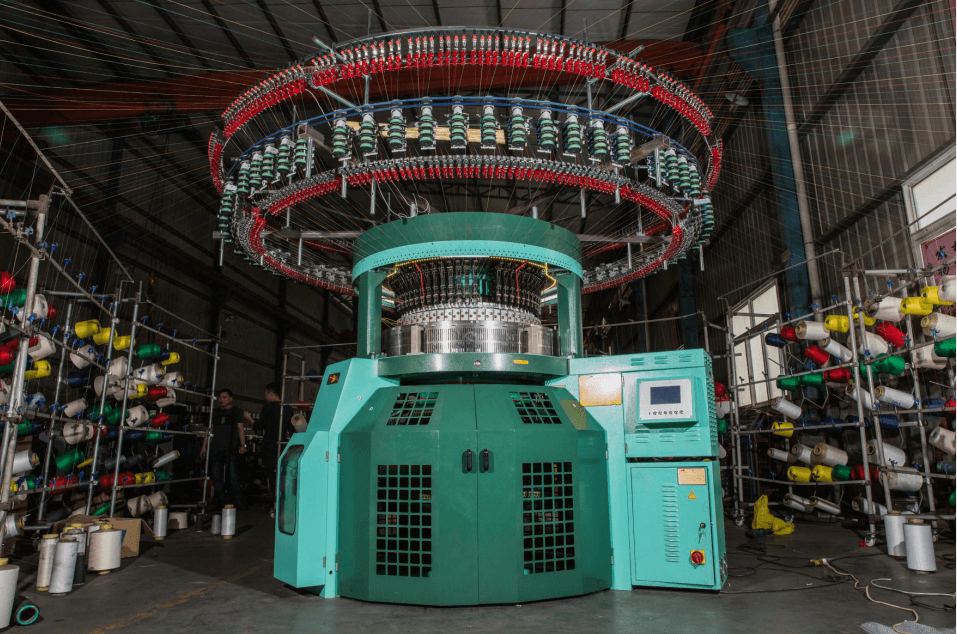

Computer Vision-Aided Fabric Inspection System for On-Circular Knitting Machine

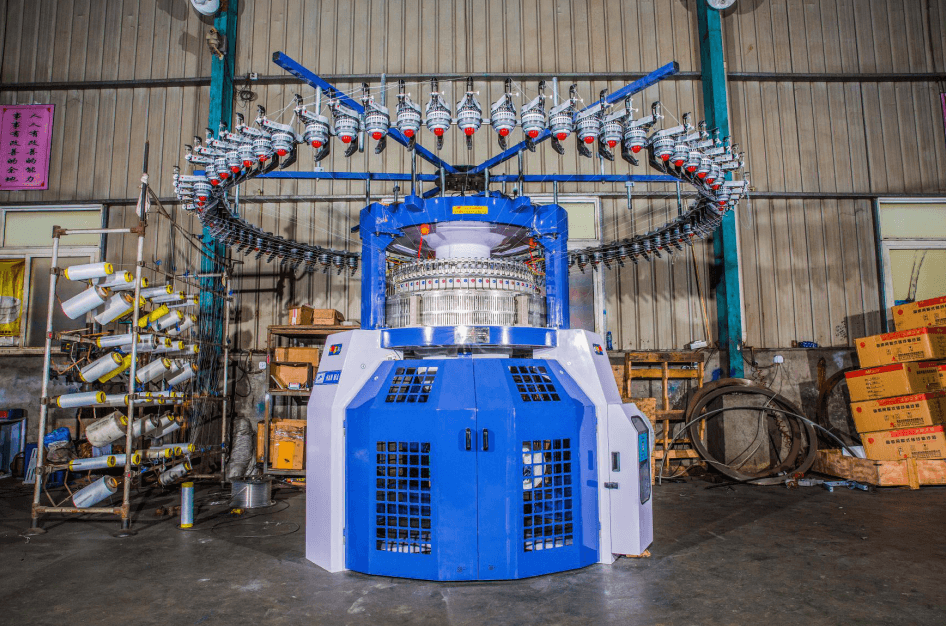

This paper describes a computer vision-based fabric inspection system implemented on a circular knitting machine to inspect the fabric under construction. The study consisted of two parts. In the first part, detection of defects in knitted fabric was performed and the performance of three different spectral methods, namely the discrete Fourier transform, the wavelet, and the Gabor transforms was evaluated off-line. In the second part, knitted fabric defect-detection and classification were implemented online. The captured images were subjected to a defect-detection algorithm, which was based on the concepts of the Gabor wavelet transform, and a neural network (as a classifier). An operator encountering defects also evaluated the performance of the system. The fabric images were broadly classified into seven main categories as well as seven combined defects. The results of the designed system were compared with those of human vision.

The 1 technical standards

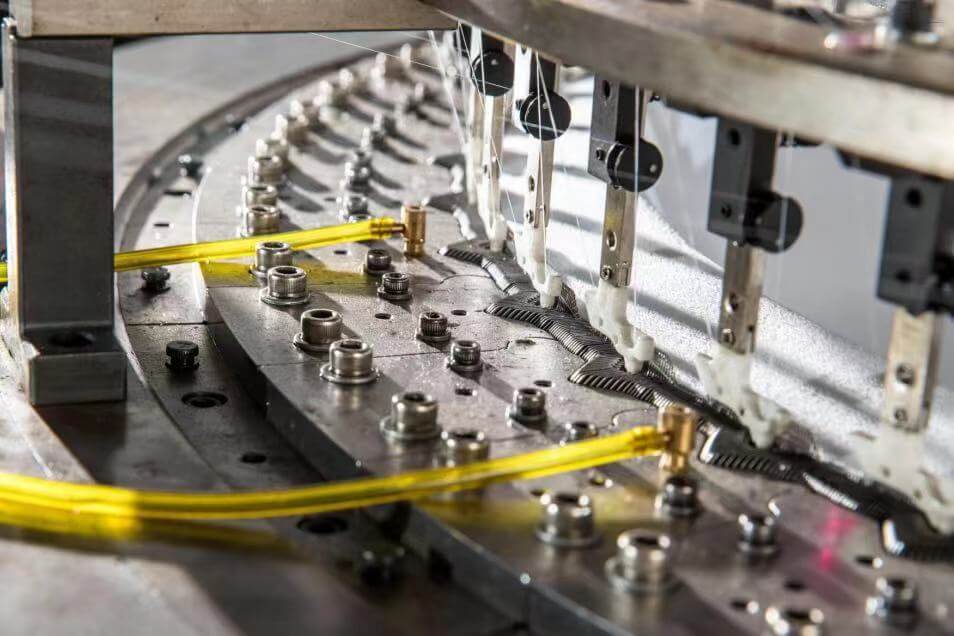

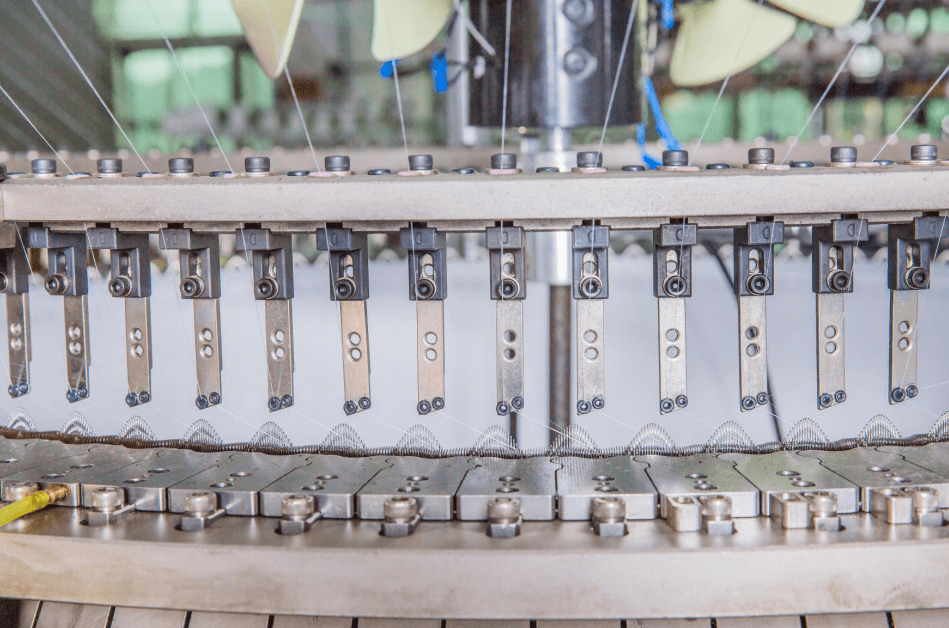

Use the dial indicator or feeler inspection

(1) on the dial from Pingdu: Standard <0.05mm

(2) on the dial from roundness: Standards <0.05mm

(3) from the needle cylinder roundness: Standards< 0.05mm

(4) the needle cylinder from Pingdu: Standard< 0.05mm

(5) the needle plate, needle cylinder co-circularity: Standard< 0.05mm

(6) the needle plate, needle cylinder co-circularity: Standard< 0.05mm

(7) clearance 0.15mm-0.20mm upper wall triangle and the needle cylinder

(8) clearance 0.15mm-0.20mm triangle and the needle cylinder lower ring

The 2 primary adjustment

In order to use the machine more safe and efficient, machine before using the

following examination and primary adjustment.

(1) motor drive check when the power is connected, please be sure to immediately

check the direction of the drive motor, the motor drive, and motor shell tags shown in

different directions, the wiring must be changed immediately (motor in the motor

terminal box, three-phase in two relatives too)

(2) motor drive belt check and adjustment start work before, please check the

drive belt tension, applying 1-1.8kg in the middle-pressure belt, the beltline deformation

should not be more than 3.5mm, too loose or too tight should immediately adjust until

it reaches the requirement. Adjustment methods are as follows: loosen the motor seat fixed

screws, moving motor outward or inward, to tension after reaching the required locking

screws Note: the first three days after the operation, recheck once, after every three

months to do an inspection

(3) dust blowing system adjustment

Fan dust blowing system should make a specific adjustment, the fan in the best position,

so that its power rotation, can reach every corner in the yarn.

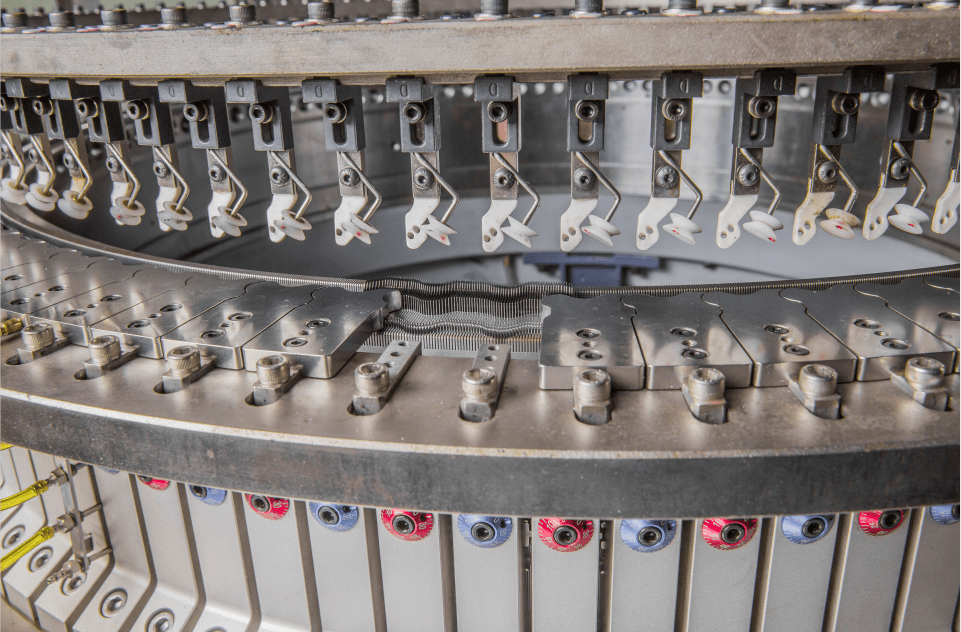

(4) yarn feeding transmission system adjustment

Fine adjustment of A yarn feeding aluminum plate feeding aluminum disc diameter, can serve to fine-tune the transmission ratio, changing the feeding amount, adjustment methods are as follows: first-round nut wrench to loosen the yarn feeding aluminum plate at the top of the. The upper cover rotates to the “+” direction, aluminum plate 12 blocks the outward expansion, increasing the diameter of the wheel body, thereby increasing the feeding quantity, instead, to “-” the direction of rotation, sliding adduction, wheel diameter reduced, yarn feeding amount will also reduce the surface cover rotation process.

According to keep parallel, otherwise, the slider may fall from the grooves. yarn feeding The aluminum disc diameter adjustable range is 70mm-200mm. aluminum plate after the adjustment, the new lock nut. Yarn feeding aluminum plate do adjustment, coping with yarn feeding transmission belt to adjust the tension. Adjust the tension of B yarn feeding belt if the drive belt is too loose, the yarn storage device will slip stop, the influence of yarn, so before starting with yarn feeding transmission belt following adjustment: loosen the roller screw, the rollers outward along with the sliding rod pull move, this should make the belt in the yarn storage device of the whole ring. Uniform stress. A locking screw.

(5)the examination of grease lubrication The lubricating condition of each part and check the transmission system and batching system, a daily supplement of grease lubrication, to avoid the lack of grease lubrication wear parts.

Related Product

Computerized Single Jersey Auto-Striper circular Knitting Machine

Computerized Single Jacquard Circular Knitting Machine

Computer Jacquard circular knitting machine

DOUBLE JERSEY JACQUARD CIRCULAR KNITTING MACHINE

DOUBLE JERSEY AUTO-STRIPER CIRCULAR KNITTING MACHINE (FOUR/SIX COLORS)

DOUBLE RIB JACQUARD CIRCULAR KNITTING MACHINE

Related Article

What is heat-setting knowledge?

circular knitting machine guide

what is Basic knowledge of circular knitting

What is the Knowledge of knitted fabrics

what is the kind of circular knitting machine

Circular knitting machine basic operation knowledge

Read moreCircular knitting machine basic operation knowledge